Jig and method for testing static curl of flexible material

A technology of flexible materials and test fixtures, which is applied in the direction of analyzing materials, testing the strength of materials by applying a stable bending force, measuring devices, etc., and can solve the problems of no measuring equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention.

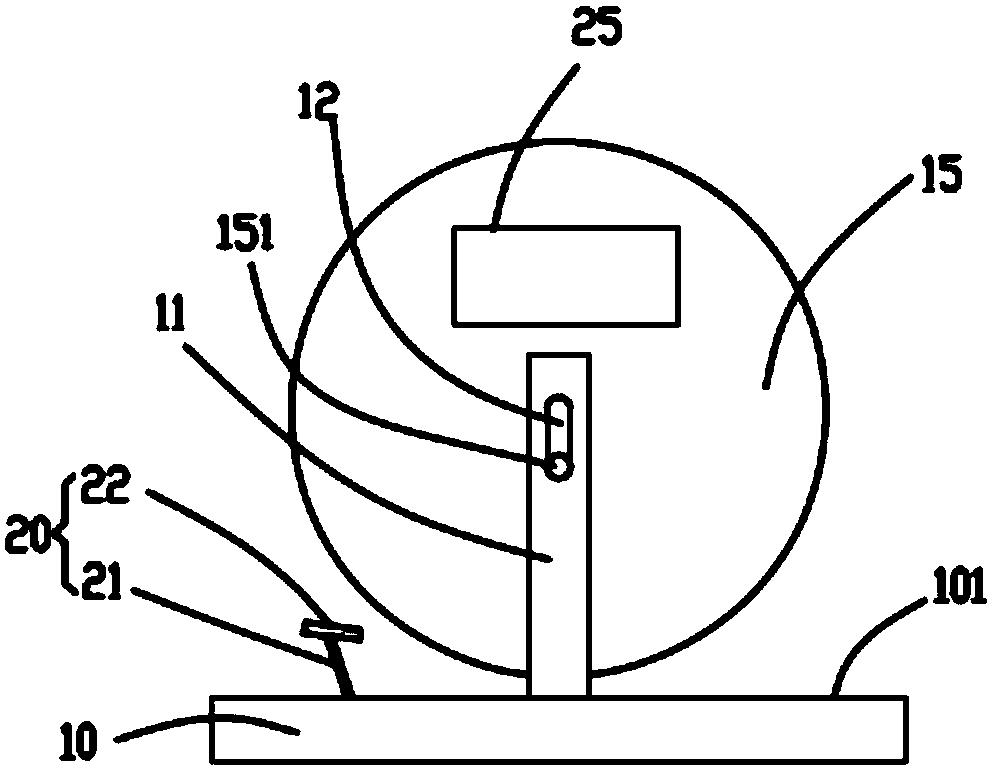

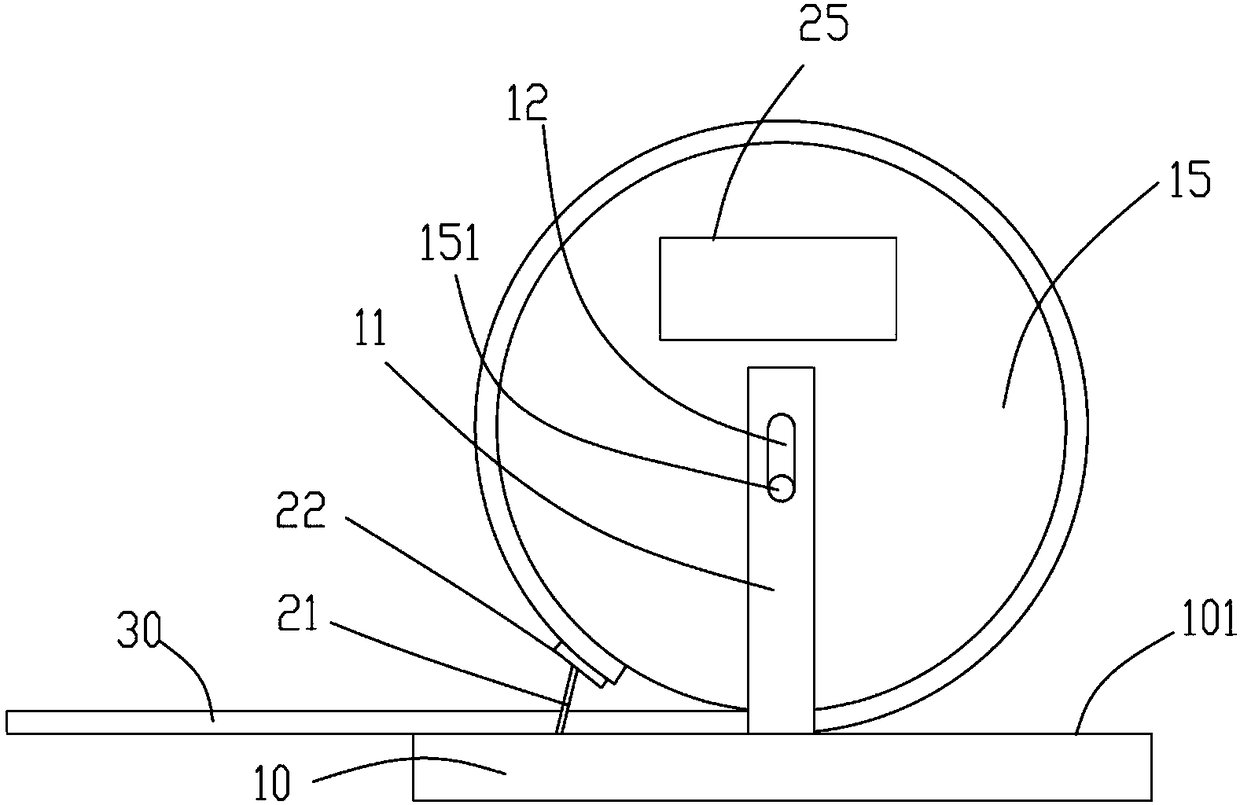

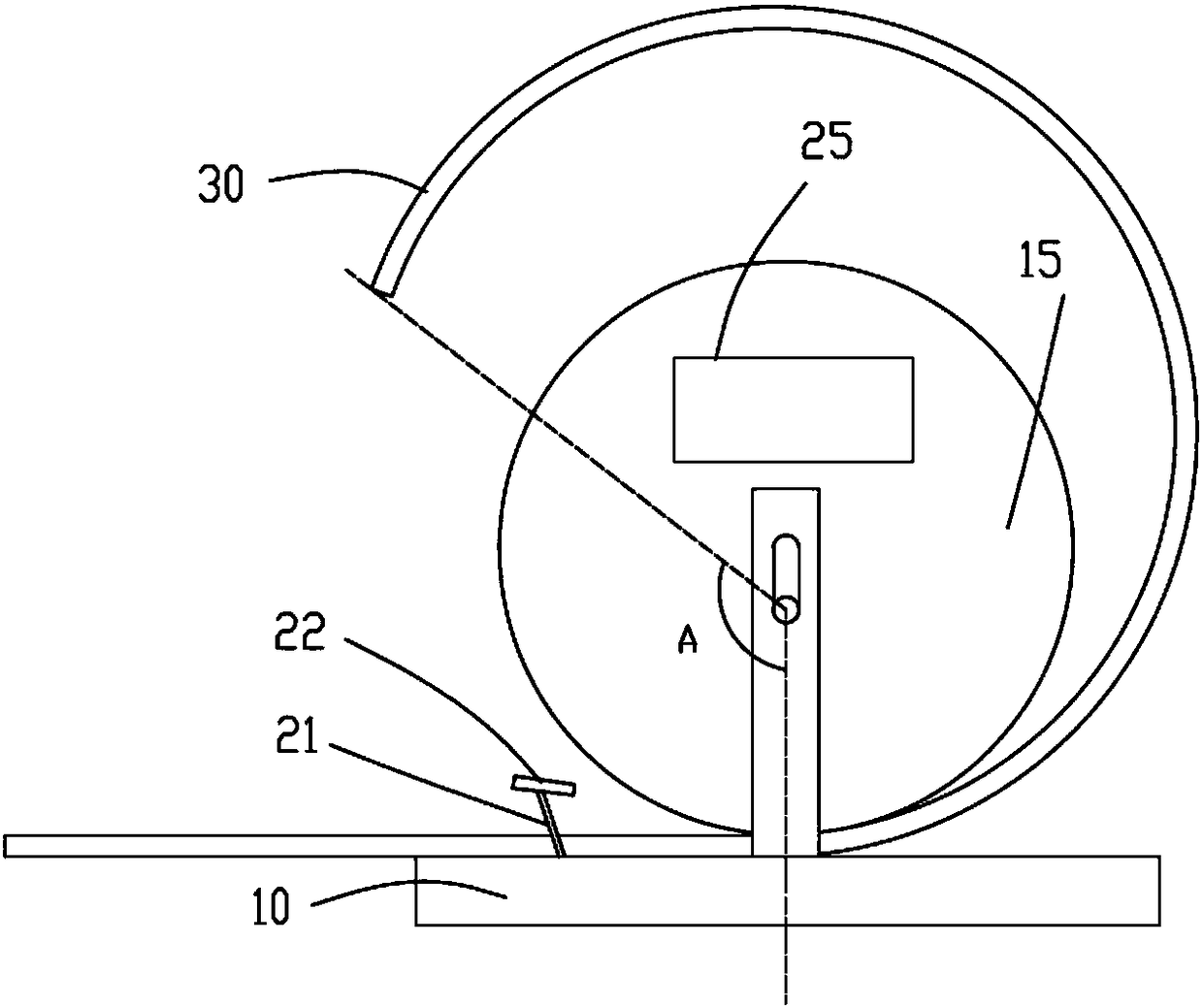

[0042] see figure 1 and figure 2 , the present application provides a flexible material static crimp test fixture for testing the recovery characteristics of a flexible material used in a flexible electronic device from a crimped state to a stretched state. The test fixture includes a base 10 , a curved surface carrier 15 , a limiter 20 and a control device (not shown). The curved surface carrier 15 is detachably mounted on the base 10 ; the curved surface of the curved surface carrier 15 is used to curl and carry the flexible material 30 . A part of the flexible material 30 is placed on the surface of the base 10 and is held between the curved surface carrier 15 and the surface of the base 10 , and the end is positioned by the limiter 20 , wherein the flexible mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com