Water and electricity integrated diesel intelligent heating device

An intelligent heating and integrated technology, applied in the direction of fuel heat treatment device, charging system, engine components, etc., can solve the problems of user safety hazards, waste, high cost, etc., achieve high application reliability, ensure application quality, and reduce operation cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

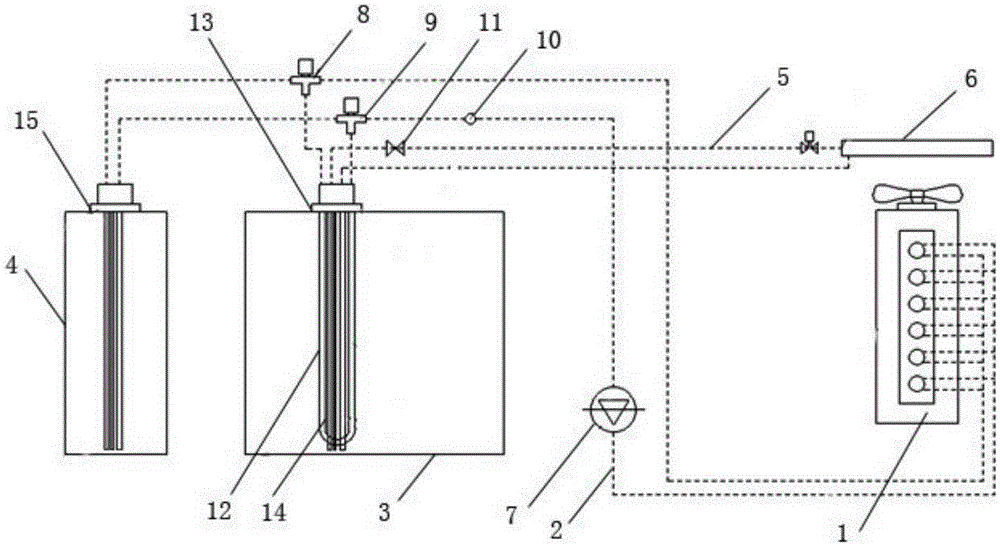

[0028] An embodiment of the present invention provides a water and electricity integrated diesel intelligent heating device, see figure 1 , the hydroelectric integrated diesel intelligent heating device includes an engine 1, a main fuel tank 3 and an auxiliary fuel tank 4 communicated with the engine 1 through a heating oil supply pipeline 2, and an engine water inlet and outlet 6 communicated with the main fuel tank 3 through a circulating water pipeline 5 , oil pump 7, oil return regulating tee 8, oil suction regulating tee 9 and filter 10 arranged in sequence on the heating oil supply pipeline 2, regulating valve 11 arranged on the circulating water pipeline 5, arranged in the main oil tank 3 The inner water circulation heating pipeline 12, the water electric oil quantity sensor 13 and the fuel tank electric heater 14 arranged at the end of the water circulation heating pipeline 12, and the integrated oil quantity sensor 15 arranged at the end of the auxiliary fuel tank 4. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com