Magnetic gear composite multiport wave power generator

A magnetic gear and multi-port technology, applied in ocean energy power generation, engine components, machines/engines, etc., can solve problems such as low efficiency, narrow controllable bandwidth, poor stability, etc., achieve high torque density, eliminate friction loss, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

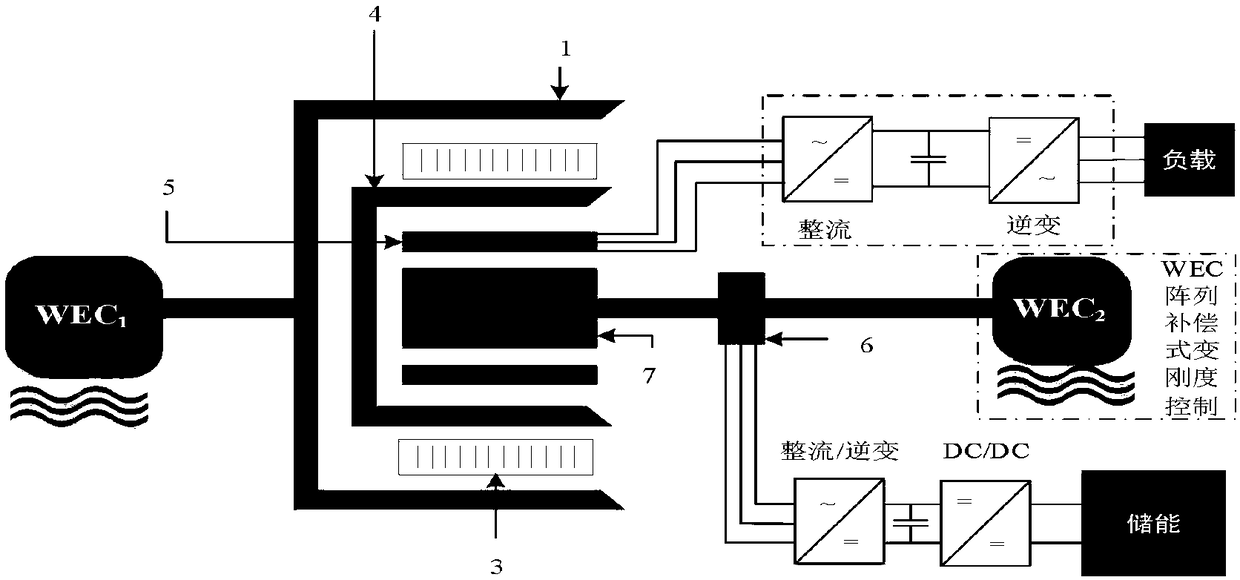

[0018] The invention provides a magnetic gear composite multi-port wave generator. When working in the power generation state, it can be applied in new energy development fields such as wave power generation. It directly converts the low-speed motion of the wave energy conversion device into high-speed motion and generates power, increasing the power density of the entire system.

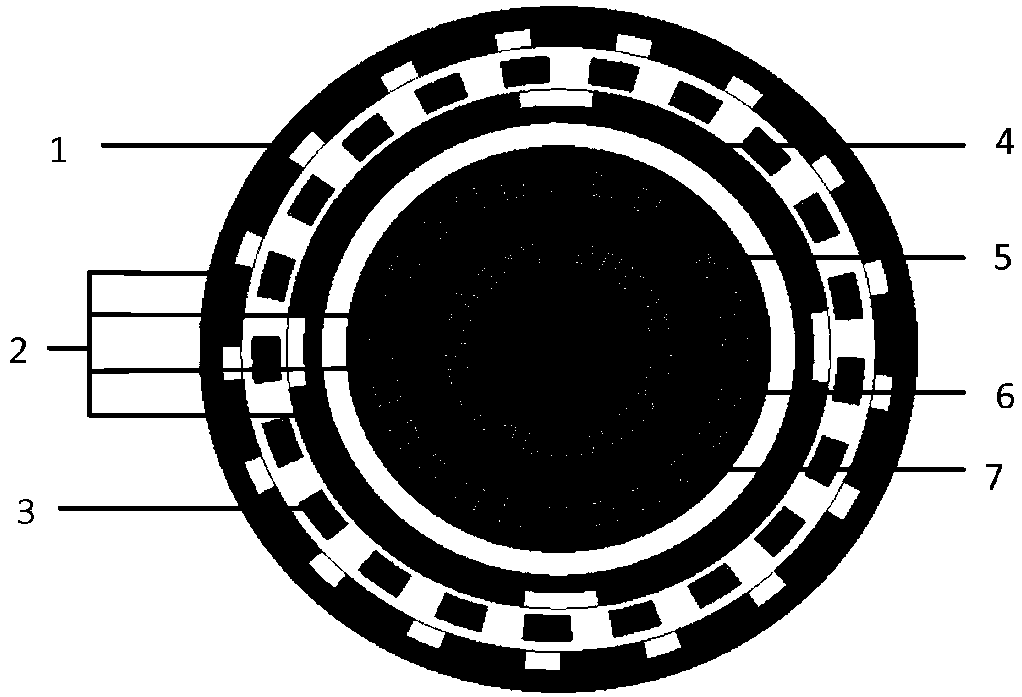

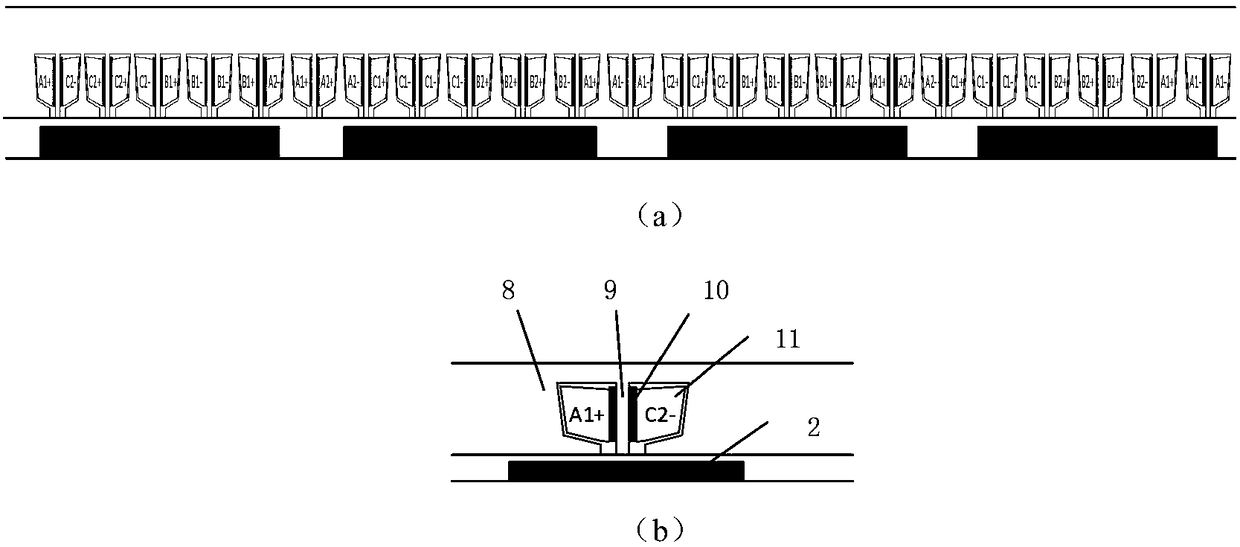

[0019] Structurally, the motor is mainly composed of five concentric parts. The inner rotor 7 of the motor, the stator 5 of the motor, the inner rotor of the magnetic gear (the outer rotor of the motor) 4, the magnetic adjustment ring 3 and the outer rotor of the magnetic gear are arranged in sequence from the inside to the outside. 1. Specifically, the magnetic gear composite multi-port wave generator can be equivalently composed of a coaxial magnetic gear and an inner rotor permanent magnet motor. Wherein the coaxial magnetic gear is composed of a magnetic gear outer rotor 1, a magnetic adjustmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com