Internet of things perception method for furniture flexible production

A flexible, Internet of Things technology, applied in the field of Internet of Things perception, can solve problems such as increasing the difficulty of production management, different production processes, low flexibility, etc., to improve the level of visualization, eliminate inspections, and save time for goods inventory. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

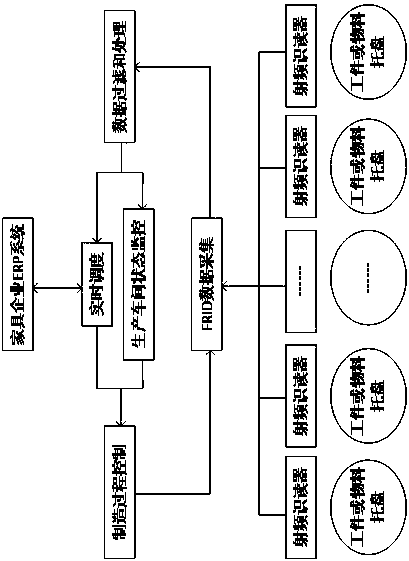

[0021] The Internet of Things sensing method for furniture flexible production in this embodiment refers to data collection, data filtering and processing methods, that is, the reader communicates with a PC through a serial port or a network. The PC is connected to the database server through the local area network. During the production process, the application system monitors the electronic tags in the effective range of the reader, and collects the information in the tags. The collected real-time production data is transmitted, filtered and processed by the middleware. , saved to the enterprise database, the furniture manufacturing process management and control system monitors the entire production process, the database is shared within the enterprise LAN, each component forms a fixed ID number through the nesting system, and is associated with an electronic label, and is transferred to In the feeding buffer zone, during processing, the electronic tag is scanned within the ...

specific Embodiment approach 2

[0029] Different from Embodiment 1, in this embodiment, an Internet of Things sensing method oriented towards flexible furniture production, the collection and processing of raw material storage information in Step 1 is as follows: the warehouse administrator returns the inventory materials After class coding, bind it to the RFID tag, read and write the information of the material in and out of the warehouse through the handheld reader, and upload the relevant information to the system database; receive the raw material demand information prompted by the system, and check the system inventory In the current situation, the required raw materials are taken out, handed over to the production material distribution personnel, and transported to the designated processing station. Fixed electronic tag readers are installed around the warehouse, and the entire furniture production warehouse is monitored through PCs and fixed readers. dynamic monitoring.

specific Embodiment approach 3

[0030] Different from the first or second specific embodiment, in this embodiment, an Internet of Things sensing method oriented towards the flexible production of furniture, the material acquisition and material cutting information collection and processing described in step 2 are as follows: ERP system every day Automatically assign individual production tasks, individuals go to the workshop control room to swipe their cards, the system automatically prints their work tasks, and issues raw material access requirements to the storage terminal. After receiving the raw material demand information, the warehouse checks the status of the system inventory and takes out the required raw materials. The personnel are transported to the designated processing station, and the raw material information is automatically imported into the system through the handheld terminal by the material cutting personnel to scan and confirm the receipt of the raw materials. The material cutting personnel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com