Automobile integrated heat radiation module

An integrated heat dissipation and automobile technology, applied in the direction of indirect heat exchanger, heat exchanger type, dispersed particle separation, etc., can solve the problems that are difficult to meet, the heat of the radiator core is quickly taken away, and the performance of the car is affected, so as to improve the performance of the car. The effect of cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

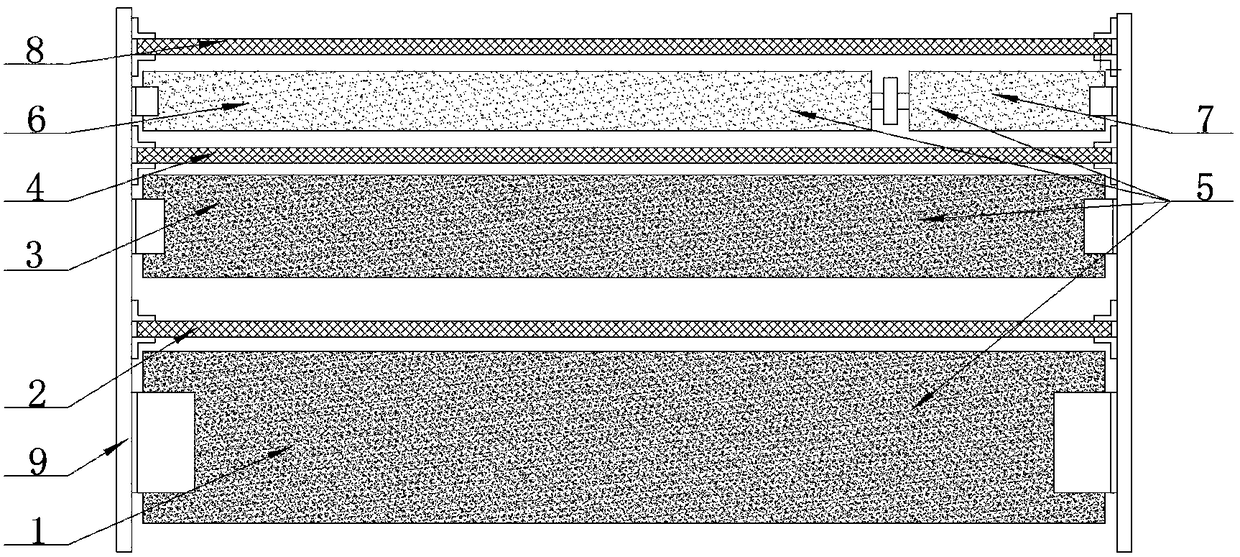

[0015] Such as figure 1 As described above, it is an integrated heat dissipation module for an automobile, including a radiator 1 for dissipating heat from the power system of the automobile, and a first net box 2 is provided on the windward side of the radiator 1, and the first net box 2 is filled with extremely easy The calcium chloride granular matter that absorbs water is provided with condenser 3 on the windward side side of the first net cage 2, and the second net cage 4 that is filled with calcium chloride granular matter is provided on the windward side side of condenser 3, in the second One side of the windward side of the cage 4 is provided with an intercooler 6 and an oil cooler 7 side by side, and the intercooler 6, the oil cooler 7, the condenser 3 and the radiator 1 are collectively arranged together, which not only saves space, but also To facilitate heat dissipation, the surfaces of the radiator 1, condenser 3, intercooler 6 and oil cooler 7 are covered with si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com