Method for extracting polysaccharide of dendrobium officinale

A technology for Dendrobium officinale polysaccharide and Dendrobium officinale, which is applied in the field of extracting Dendrobium officinale polysaccharide and achieves the effects of high extraction rate, low volatility and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

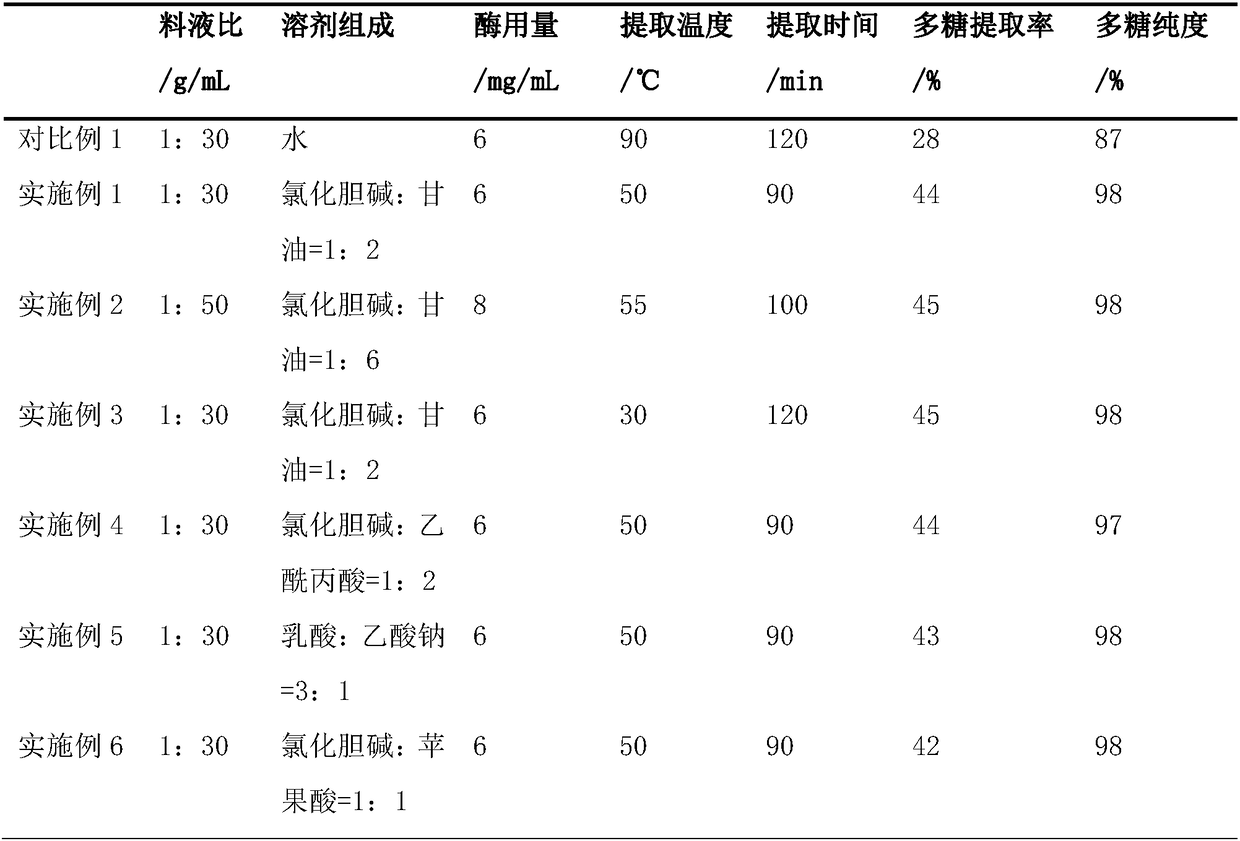

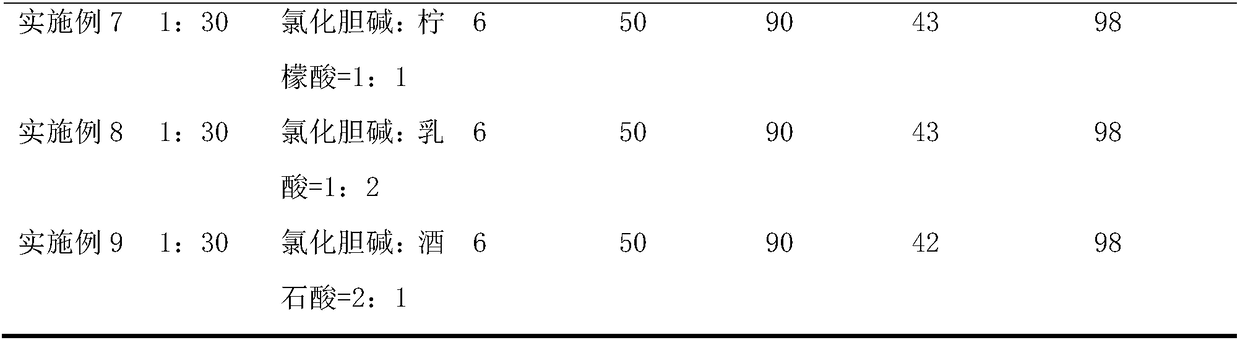

Examples

Embodiment 1

[0028] (1) Mix the Dendrobium officinale powder with the deep eutectic solvent (choline chloride: glycerol=1:2, mol / mol) according to the solid-liquid ratio of 1g: 30mL, then add the compound enzyme ( Cellulase: pectinase=1:1, mg / mg), extracted at 50°C for 90min;

[0029] (2) The obtained extract is subjected to solid-liquid separation, and the supernatant is purified with macroporous resin AB-8 to obtain crude sugar liquid;

[0030] (3) Then use a dialysis bag (3500Da) to dialyze the crude sugar solution in running water for 24 hours, then dialyze it in distilled water for 24 hours, change the distilled water every 8 hours, and then vacuum concentrate it to 1 / 4 of the original volume at 50°C. Add 95% ethanol solution equivalent to 4 times the volume of the concentrated solution to precipitate the polysaccharide. Specifically, during the precipitation process, add slowly while stirring, first add an ethanol solution equal to the concentrated solution to precipitate the polysac...

Embodiment 2

[0037] (1) Mix the Dendrobium officinale powder with the deep eutectic solvent (choline chloride: glycerol=1:6, mol / mol) according to the solid-liquid ratio of 1g: 50mL, then add the compound enzyme ( Cellulase: pectinase=1:1, mg / mg), extract at 55°C for 100min;

[0038] Steps (2)-(4) refer to Example 1.

[0039] The extraction rate of polysaccharide was determined to be 45%, the recovery rate of polysaccharide separated and purified by AB-8 macroporous resin was 96%, the decolorization rate and protein removal rate were 98% and 98% respectively, and the purity of the final purified polysaccharide was 98%.

Embodiment 3

[0041] (1) Mix the Dendrobium officinale powder with the deep eutectic solvent (choline chloride: glycerol=1:2, mol / mol) according to the solid-liquid ratio of 1g: 30mL, then add the compound enzyme ( Cellulase: pectinase=1:1, mg / mg), extracted at 30°C for 120min;

[0042] Steps (2)-(4) refer to Example 1.

[0043] The extraction rate of polysaccharide was determined to be 45%, the recovery rate of polysaccharide separated and purified by AB-8 macroporous resin was 97%, the decolorization rate and protein removal rate were 97% and 98%, respectively, and the purity of the final purified polysaccharide was 98%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com