Sludge in-situ treatment device

An in-situ sludge treatment technology, applied in the field of machinery, can solve problems such as the impact on the ecological environment of river slopes, increase the area occupied by sludge storage yards, and increase the cost of temporary cofferdams, so as to achieve strong economic benefits and promotional power, reduce Project operating cost, the effect of a wide range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The purpose of this embodiment is to provide a device capable of improving the water quality of a river.

[0039] This embodiment specifically provides an in-situ treatment device for sludge, which is used for mechanical equipment, especially equipment with a hydraulic system, such as tractors, dredgers, and wheel excavators. The in-situ sludge treatment device is installed at the front end of the arm of the excavator, and is connected to the arm of the excavator by a connecting component. Its main function is to stir the river sediment and inject chemicals.

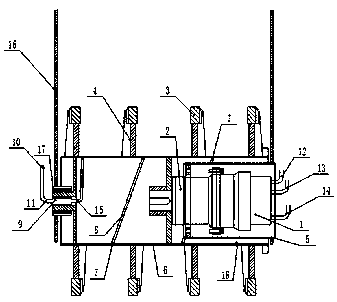

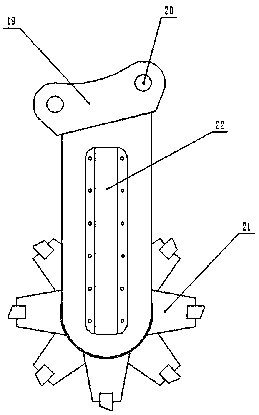

[0040] The sludge in-situ processing device at least includes a sludge stirring device and a powder delivery device; the sludge stirring device is installed on the small arm of the excavator through the connecting shaft 20 installed on the connecting assembly 19 of the fixed body 16 .

[0041] The sludge stirring device at least includes hydraulic motor 1, transmission gear 2, milling gear 3, stirring and milling ...

Embodiment 2

[0067] In this embodiment, the hydraulic excavator is provided with an amphibious pontoon. In the wide river channel and the construction environment with deep river water, the present invention can still be used to control the silt in situ; or the hydraulic excavator can be placed on the floating boat to achieve the same purpose.

[0068] The remaining implementation modes, technical solutions and technical effects produced are the same as those in Example 1.

[0069] In the description of the present invention, it should be noted that although the present invention is applied to the field of sludge treatment and hydraulic excavators, it can also be used in other fields, such as being installed on a tractor, fertilizing the soil, loosening the ground; Installed on a pontoon with a hydraulic system, the pontoon is used to control the silt in the river; the silt stirring device in the present invention can also stir other materials (such as chemical raw materials, feed fertiliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com