Method for producing thermoprinted matt stay wire

A production method and matte technology, applied in other household appliances, flat products, household appliances, etc., can solve the problems of large color difference of paper packaging boxes, easy light transmission or unsatisfactory shading effect, large brightness and color contrast, etc. To achieve the effect of preventing random code scanning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

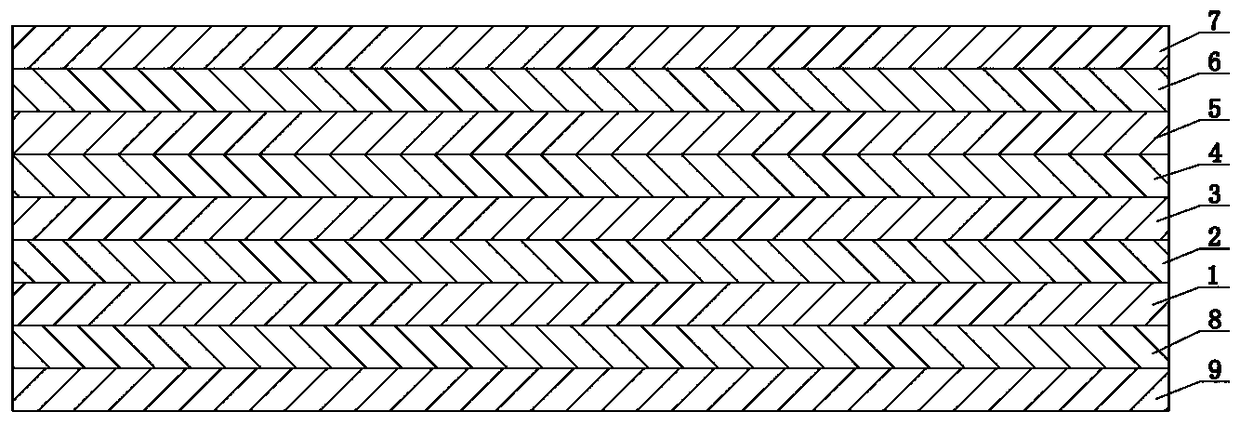

[0023] The invention provides a production method of hot stamping matte pull wire, such as figure 1 As shown, the structure of hot stamping matte pull wire includes a film base layer 1 made of BOPP plastic film or PET plastic film, an upper corona layer 2, a medium layer 3, a vacuum aluminized layer 4, Matting layer 5, printing layer 6, glue layer 7, lower corona layer 8 and release layer 9 arranged on the lower surface of film base layer 1, its production method comprises the following steps:

[0024] (a). Material selection: BOPP plastic film or PET plastic film is used as the film base layer 1;

[0025] (b). Pre-printing treatment: double-sided corona treatment is performed on the BOPP plastic film or PET plastic film substrate to form the upper corona layer 2 and the lower corona layer 8, so as to increase the adaptability of the film to the subsequent process;

[0026] (c). Medium layer 3 on the upper surface of the upper corona layer 2 and plate making: the upper surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com