An intelligent cement mixing and processing equipment

A technology for processing equipment and cement, used in cement mixing devices, clay preparation devices, mixing operation control, etc., can solve problems such as poor controllability, not particularly in place, damage to equipment, etc., to prevent congestion, increase speed power, The effect of avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

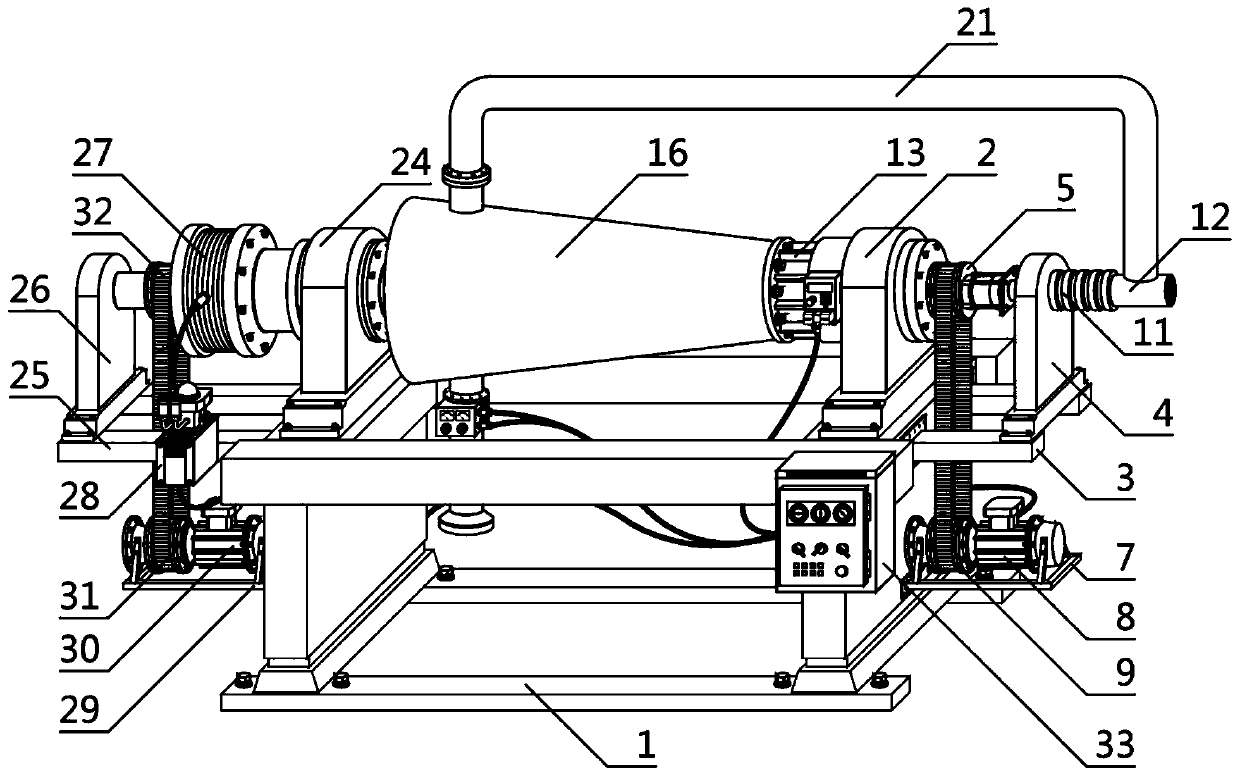

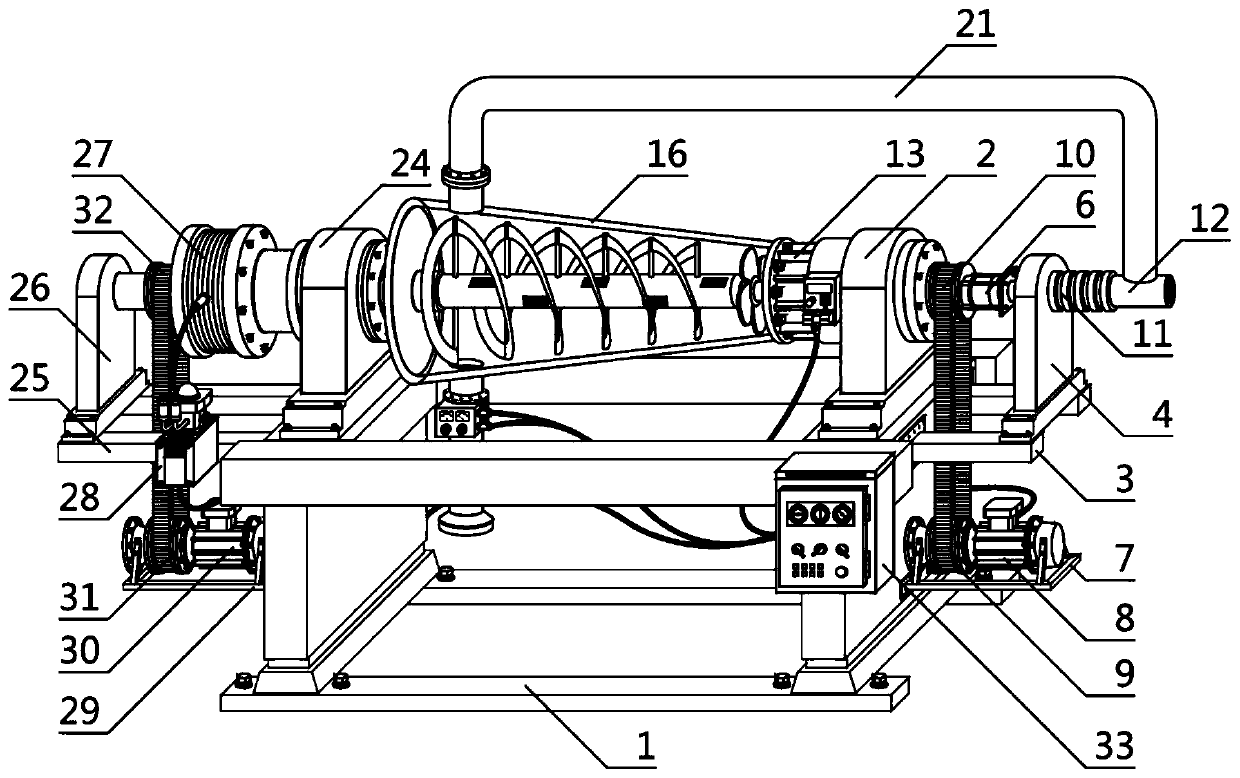

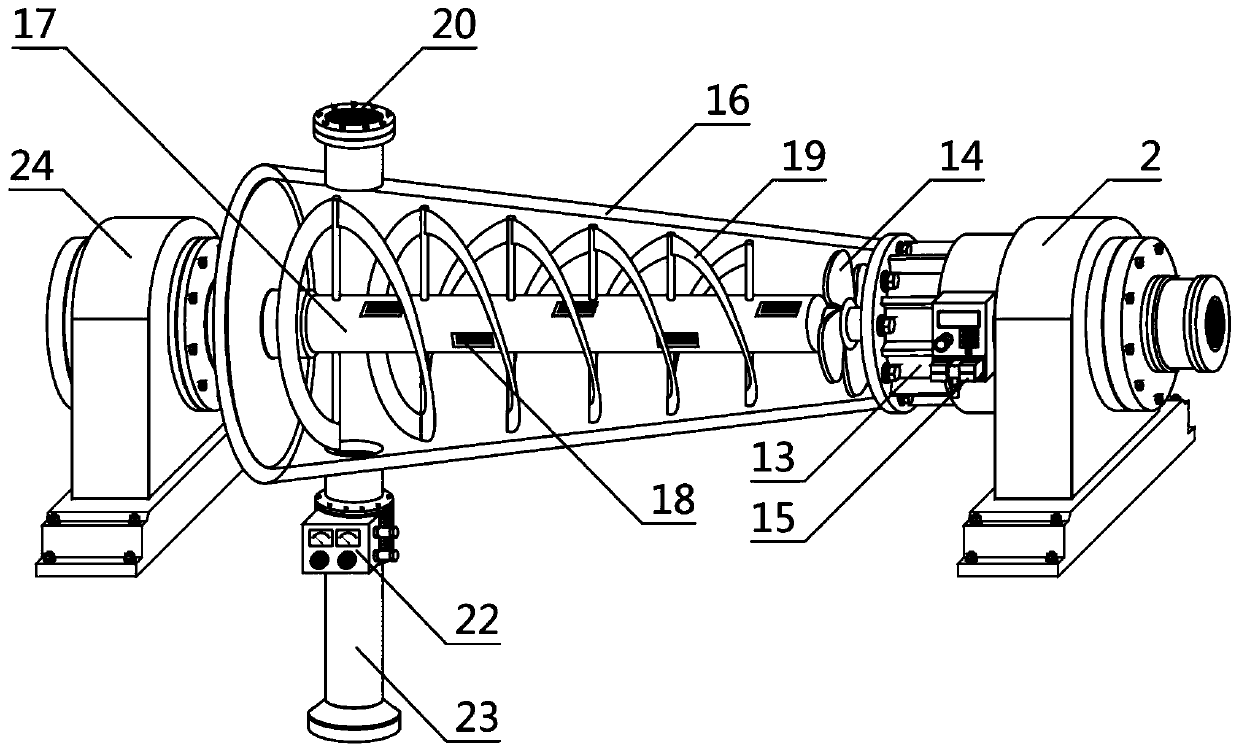

[0029] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

[0030] Such as figure 1 , figure 2 , image 3 A kind of intelligent cement mixing and processing equipment shown is characterized in that: it consists of an operating platform 1, a first bearing seat 2, a first driving support platform 3, a first driving auxiliary support 4, a first driving transmission shaft 5, and a first driving motor Support 7, first driving motor 8, feeding buffer cabin 11, feeding port 12, induction trigger device 13, stirring tank 16, stirring rotating shaft 17, second bearing seat 24, second driving supporting platform 25, second driving Auxiliary bracket 26, rotating speed regulating motor 27, second drive motor support 29, second drive motor 30 and total control box 33 are formed, and described first bearing seat 2 is positioned at the top of console 1, and described first bearing seat 2 and The oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com