Welding technology of differential mechanism assembly

A technology of welding process and differential gear, applied in welding equipment, laser welding equipment, welding/welding/cutting items, etc., can solve the problems of difficult processing, light weight, high cost, etc., to improve production efficiency and processing accuracy , light weight and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A welding process for a differential gear assembly, comprising the following steps:

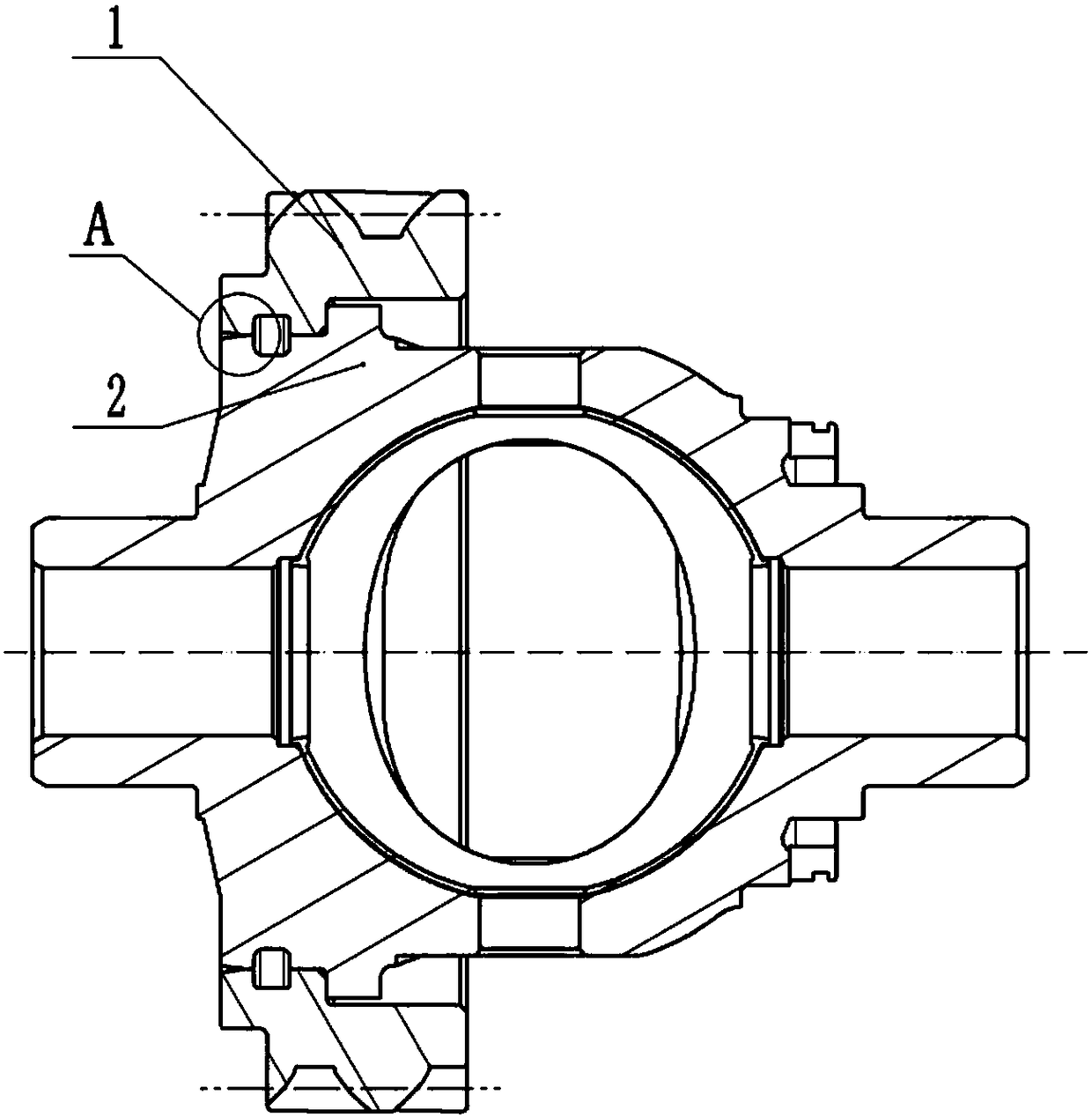

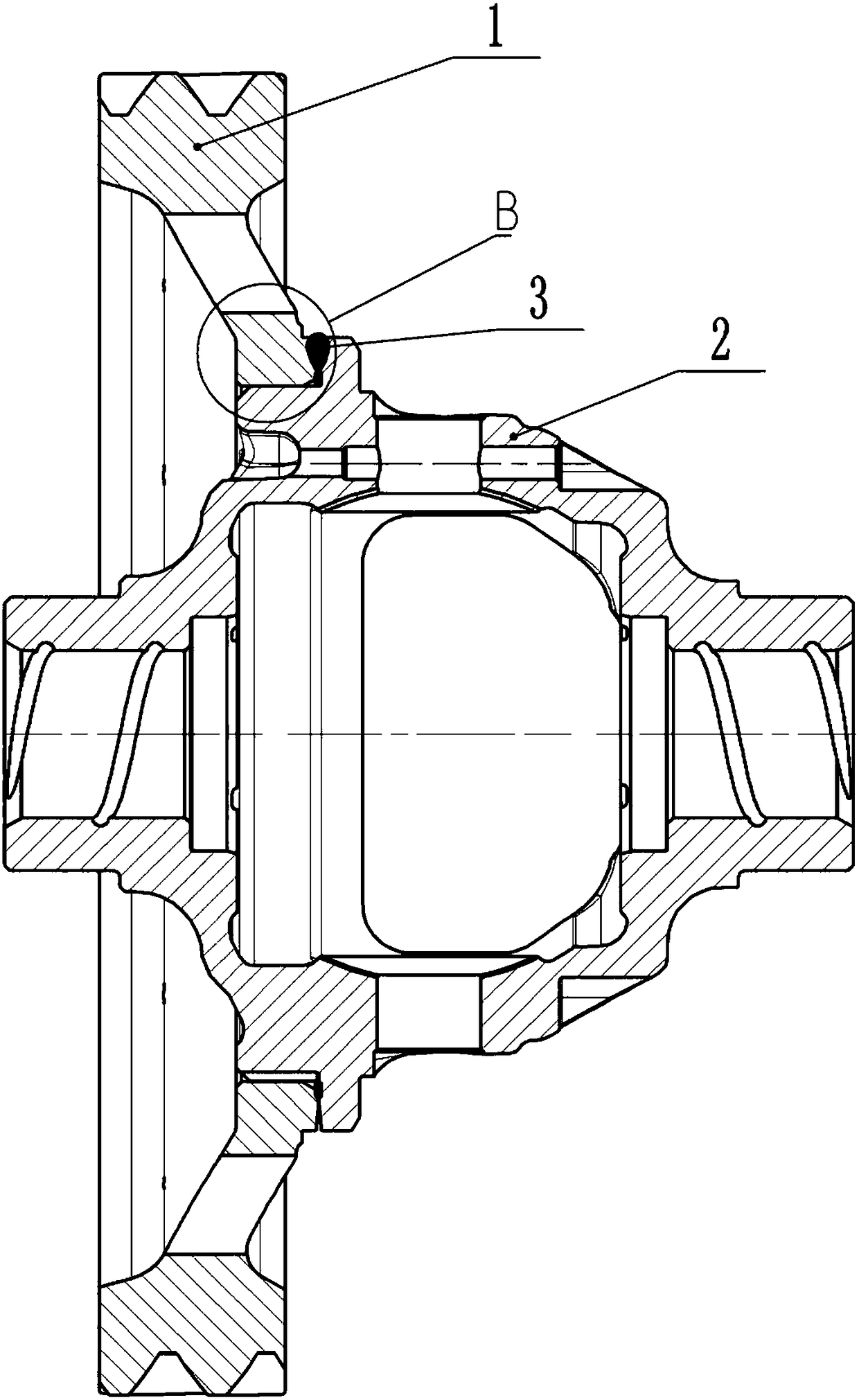

[0039] (1) The differential case 2 and the differential gear 1 that can be matched with each other are prepared, and the outside of the differential case 2 is a stepped shaft;

[0040] (2) Remove oil stains and carbon layers on the differential case 2 and the differential gear 1, and perform laser cleaning until the contact surfaces of the differential case 2 and the differential gear 1 are free of foreign matters and impurities;

[0041] (3) Set the shaft hole of the differential gear 1 on the stepped shaft portion with a smaller diameter of the differential case 2, and press the step between the differential gear 1 and the stepped shaft portion;

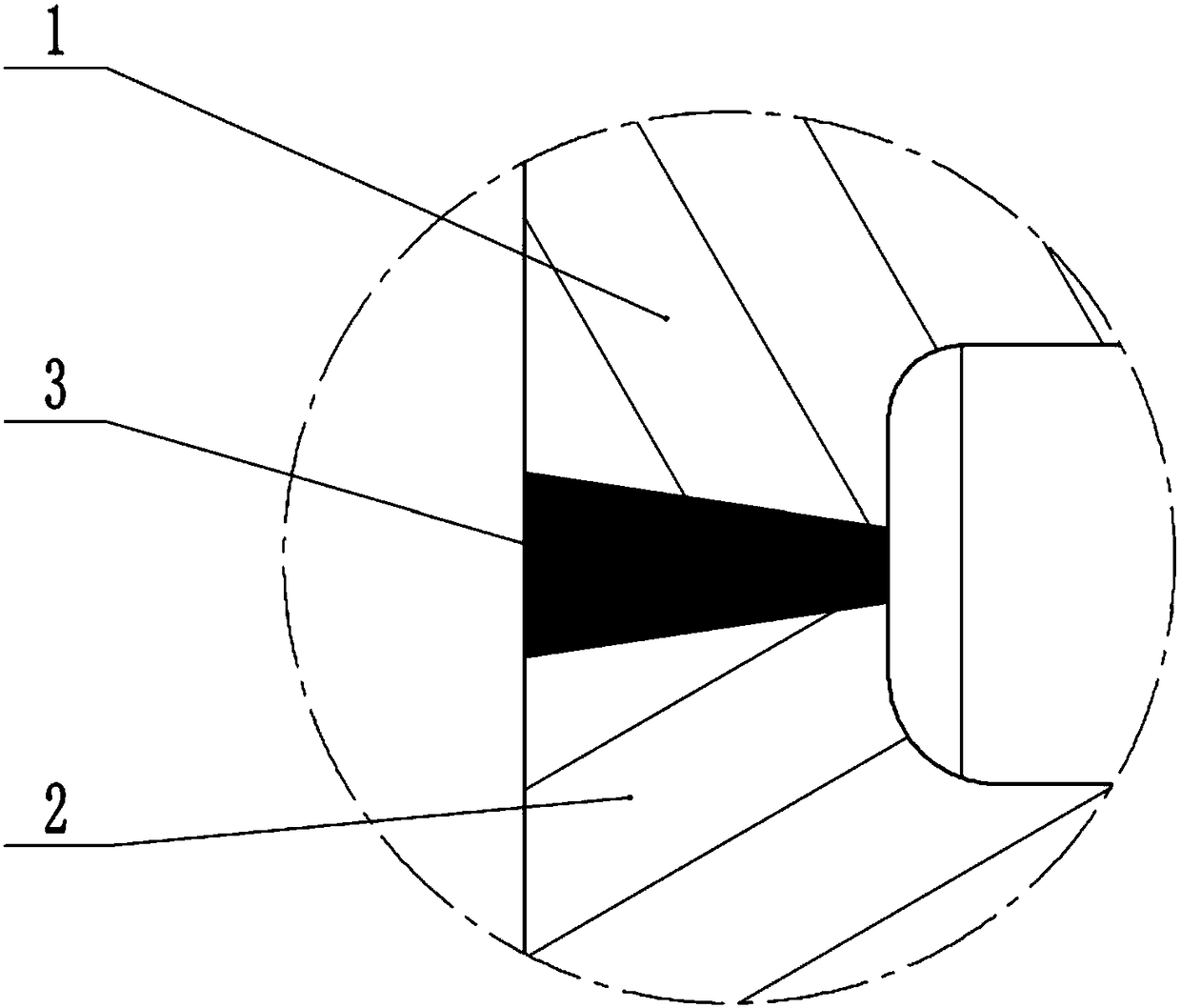

[0042] (4) Fix the differential gear 1 and the differential case 2 with a clamp, and fill the axial contact surface of the differential case 2 and the differential gear 1 with 1mm iron-nickel alloy welding wire using a welding wire filling ...

Embodiment 2

[0048]The difference between this embodiment and Embodiment 1 is that in step (4), a welding wire filling mechanism is used to fill the axial contact surface of the differential case 2 and the differential gear 1 with a 0.6 mm iron-nickel alloy welding wire In the gap, the contact surface between the differential case 2 and the differential gear 1 is evenly divided into 3 points for spot welding.

[0049] According to the commonly used dimensions of the differential case 2 and the differential gear 1, the three points of the contact surface of the differential case 2 and the differential gear 1 can be spot welded, and the two can be well connected. Preliminary fixation; using 0.6mm iron-nickel alloy welding wire can make the welding process faster.

Embodiment 3

[0051] The difference between this embodiment and Embodiment 1 is that in step (4), a 1.3mm iron-nickel alloy welding wire is used to fill the axial contact surface of the differential case 2 and the differential gear 1 by using a welding wire filling mechanism In the gap, the contact surface between the differential case 2 and the differential gear 1 is evenly divided into 6 points for spot welding.

[0052] Spot welding the 6 points of the contact surface between the differential case 2 and the differential gear 1 can be applied to many differential assemblies. Using 1.3mm iron-nickel alloy welding wire can make the welding process more efficient. firm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com