Device for repairing side door of railway open wagon

A side door and railway technology, applied in the field of railway vehicle maintenance equipment, can solve the problems of low repair rate of gondola side doors, increase in the number of scrapped side doors, economic losses of enterprises, etc., and achieve the effect of realizing reuse, saving repair costs, and reducing maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

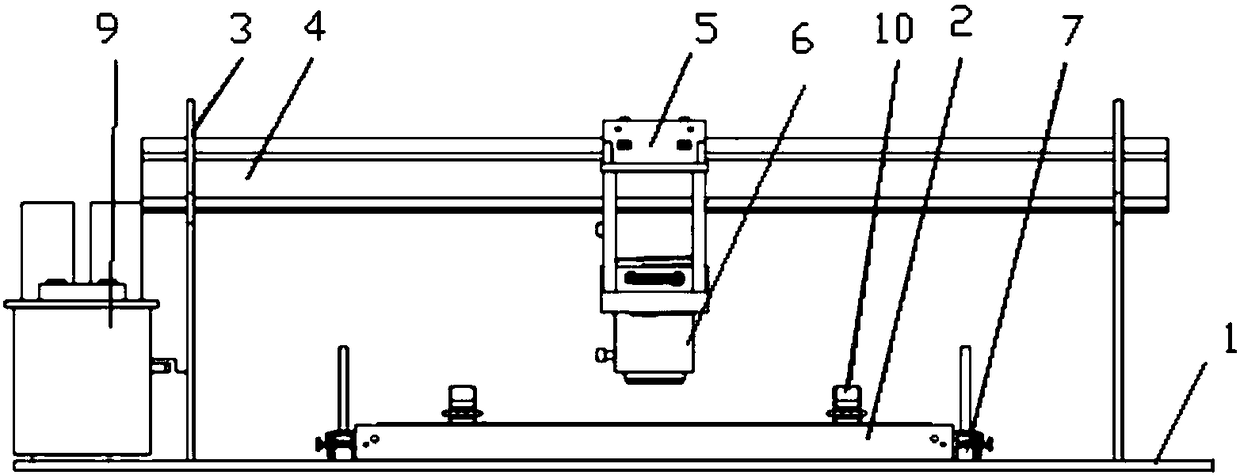

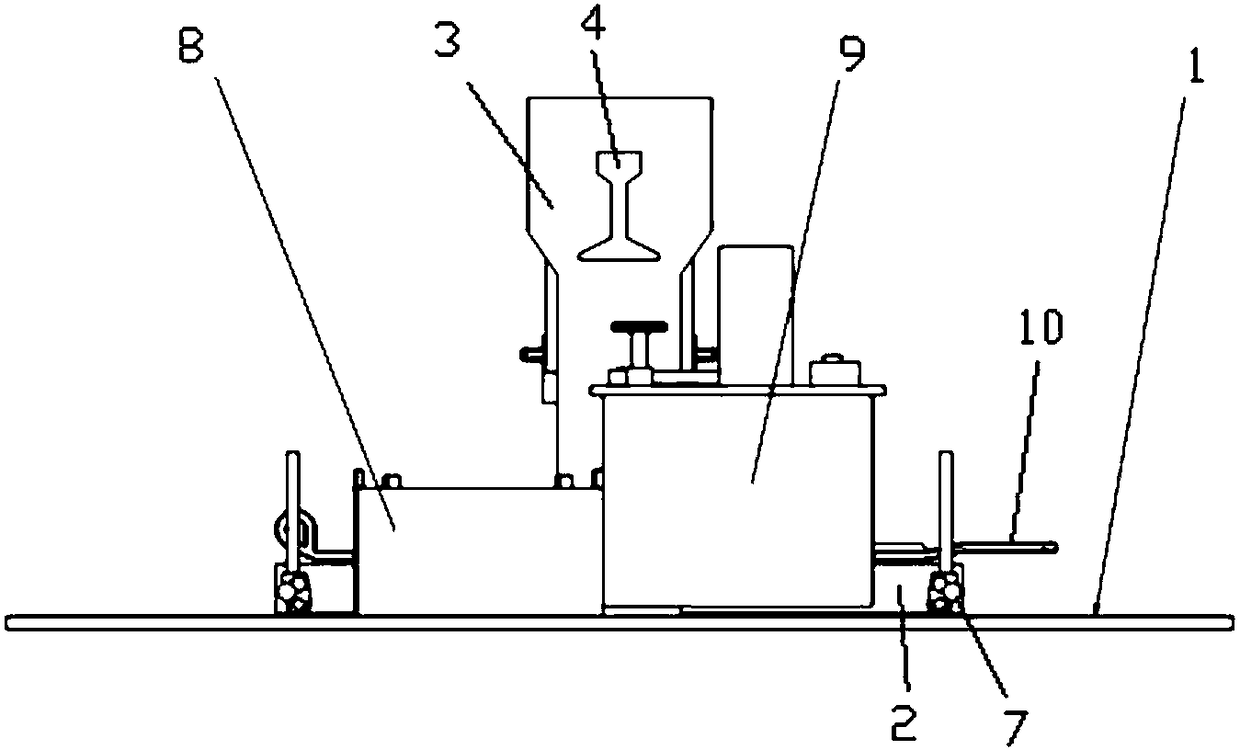

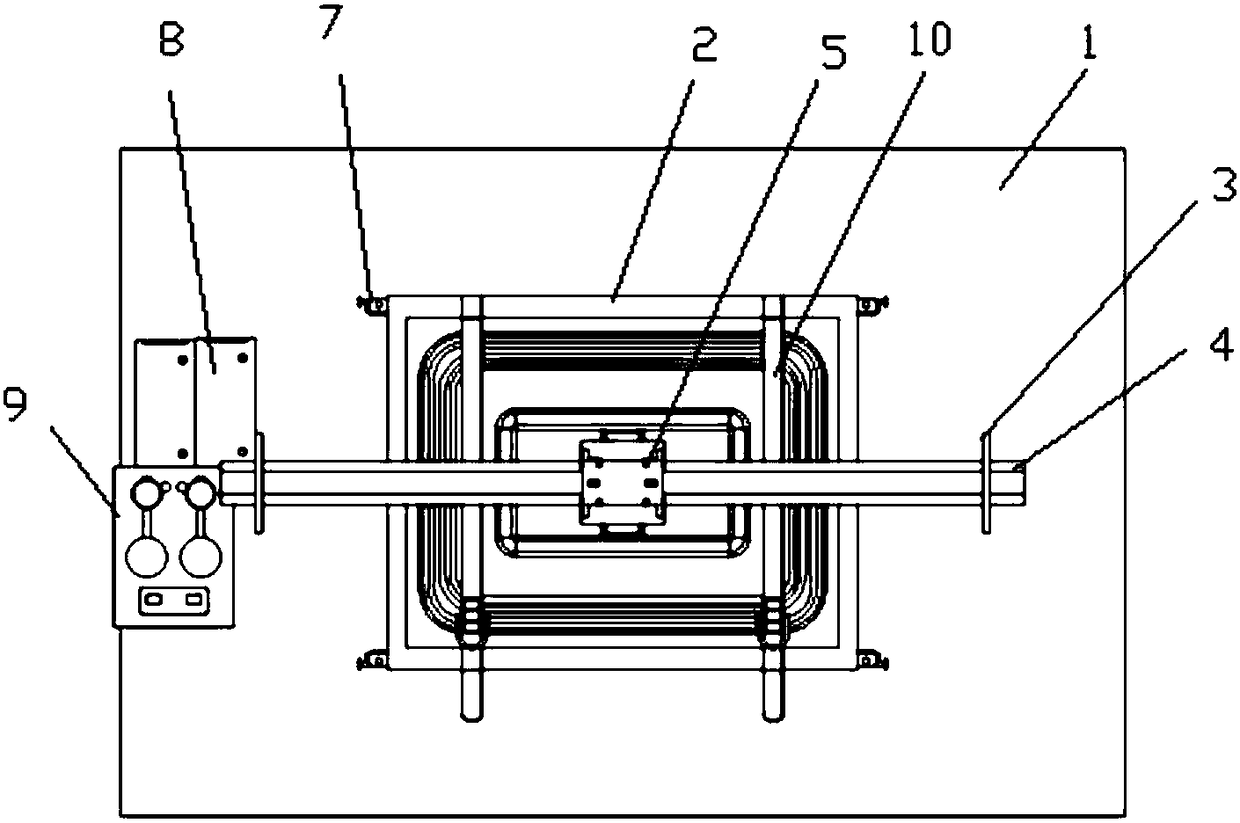

[0028] The present invention consists of a repair platform 1, a repair base 2, a support column 3, a beam 4, a hydraulic pick sliding seat 5, a hydraulic pick 6, a positioning pulley 7, a storage battery 8, and an electric hydraulic pump 9.

[0029] figure 1 , 2 , 3 shows that the repair platform 1 is fabricated by welding rectangular flat steel plates and channel steels to ensure the strength and flatness of the repair platform 1 . The steel plate of the repair platform 1 in one embodiment of the present invention is a 20mm thick steel plate.

[0030] Image 6 , 7 , 8 show that the repair base 2 is a rectangular steel frame platform, and the repair base 2 is used to place and correct the side door 10 to be repaired. When the hydraulic pick 6 was working, the repair base 2 could correct the deformed surface and play the role of a mould. The repair base 2 of an embodiment of the present invention is composed of a special steel plate with a thickness of 80 mm and a steel pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com