Modified hydroxyapatite complex polycaprolactone-chitosan double-layer membrane and preparation method thereof

A technology of hydroxyapatite and polycaprolactone, which is applied in medical science, prosthesis, tissue regeneration, etc., can solve the problems of poor biocompatibility of bone cells and failure to promote the growth of bone cells and soft tissue cells at the same time. To achieve the effect of promoting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] In the present invention, the modified hydroxyapatite is obtained by modifying hydroxyapatite with a silane coupling agent; the preparation method of the modified hydroxyapatite preferably includes the following steps: combining the silane coupling agent and hydroxyl The apatite is mixed in an alcoholic organic solvent, and then the obtained dispersion is subjected to ultrasonication, filtration, washing, centrifugation, drying and grinding in sequence.

[0045] In the present invention, the mass ratio of the volume of the silane coupling agent to the hydroxyapatite is preferably 1 mL:0.5-2.5 g, more preferably 1 mL:1.0-2.0 g. In the present invention, the silane coupling agent is preferably γ-methacryloxypropyltrimethoxysilane.

[0046] In the present invention, the volume ratio of the alcohol organic solvent to hydroxyapatite is preferably 20-30mL:10g, more preferably 22-28mL:10g, and more preferably 24-26mL:10g. In the present invention, the alcoholic organic solven...

Embodiment 1

[0085] Take 50 mL of 0.05 mol / mL calcium nitrate solution and 50 mL of 0.3 mol / mL diammonium hydrogen phosphate solution. The pH of the two was adjusted to 11 with ammonia water respectively, and the diammonium hydrogen phosphate solution was mixed with 1.0ml·min -1 Add dropwise to the calcium nitrate solution at a high speed, stir while adding dropwise, and stir the solution at 85°C for 12h after the reaction. At 25°C, sink for 12h. After centrifugation, it was repeatedly washed with water three times, and dried in vacuum at 80° C. for 24 hours to obtain hydroxyapatite.

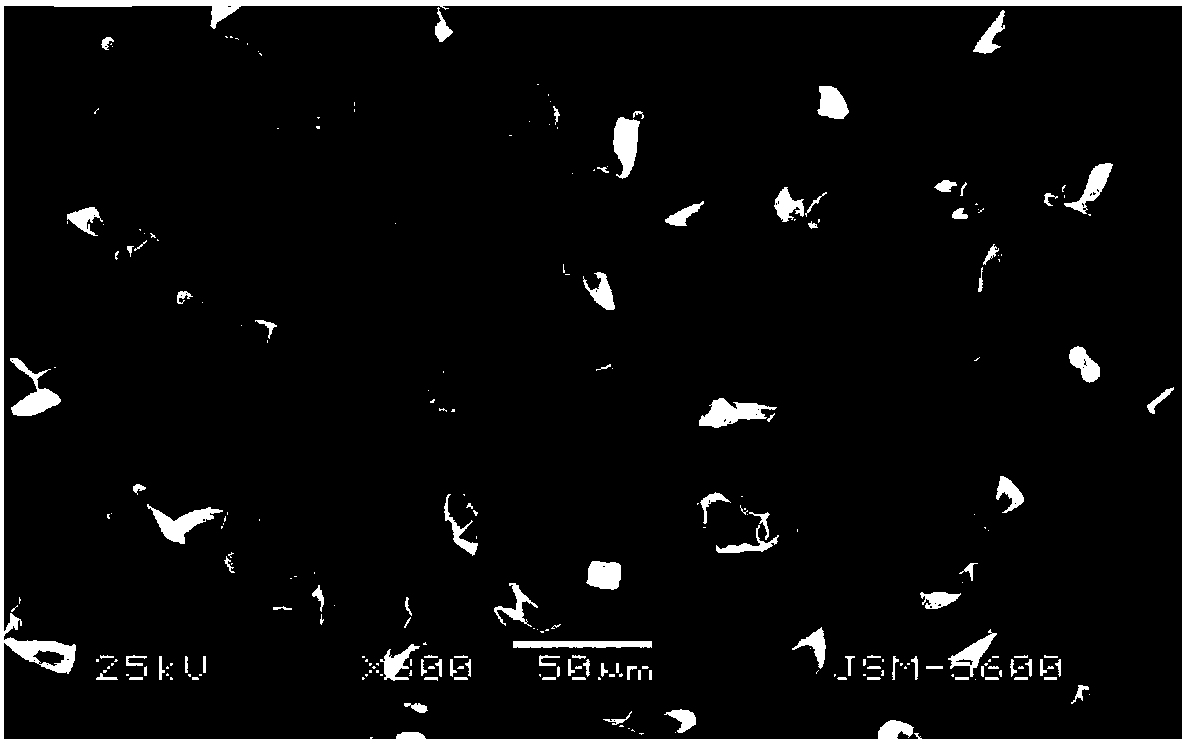

[0086] Disperse 4mL of silane coupling agent in 26mL of ethanol; disperse 10g of hydroxyapatite in 60mL of ethanol; after sonicating for 10min, mix the above two solutions, and then sonicate for 40min. Filtration after sonication yielded a mixture. The mixture was washed with ethanol, centrifuged, dried at 80°C for 2 hours, then vacuum-dried at 100°C for 24 hours, ground to obtain a sample, and passed thr...

Embodiment 2

[0090] Take 50 mL of 0.1 mol / mL calcium nitrate solution and 50 mL of 0.3 mol / mL diammonium hydrogen phosphate solution. The pH of the two was adjusted to 11 with ammonia water respectively, and the diammonium hydrogen phosphate solution was mixed with 1.2ml·min -1 Add dropwise to the calcium nitrate solution at a high speed, stir while adding dropwise, and stir the solution at 85°C for 12h after the reaction. At 25°C, sink for 12h. After centrifugation, it was repeatedly washed with water three times, dried in vacuum at 80°C for 24 hours, and hydroxyapatite was obtained.

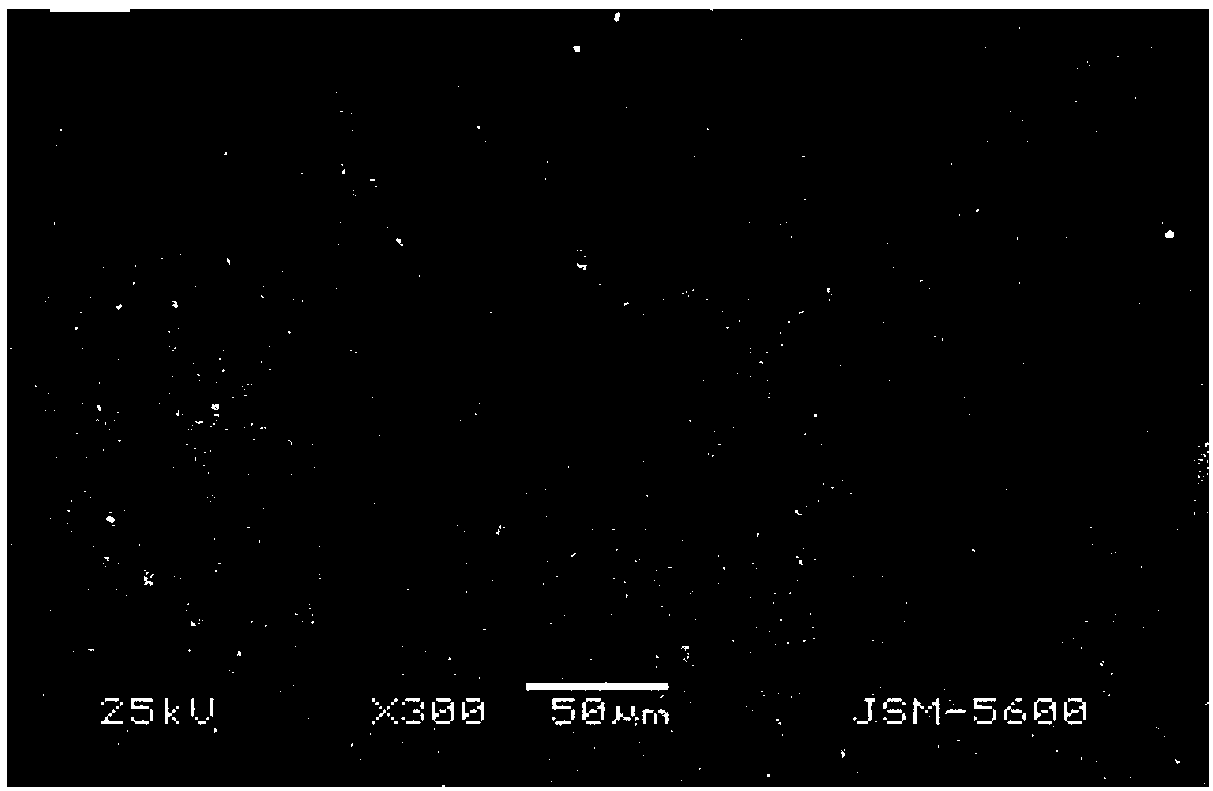

[0091] Disperse 4mL of silane coupling agent in 25mL of ethanol; disperse 10g of hydroxyapatite in 55mL of ethanol; after sonicating for 10min, mix the above two solutions, and then sonicate for 40min. Filtration after sonication yielded a mixture. The mixture was washed with ethanol, centrifuged, dried at 80°C for 2 hours, then vacuum-dried at 100°C for 24 hours, ground to obtain a sample, and passed th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com