Method for preparing lithium-sulfur battery positive plate by means of ion beam sputtering technology

An ion beam sputtering, lithium-sulfur battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of sulfur agglomeration, complex processes, restrictions, etc., to reduce interface resistance, simplify manufacturing processes, and improve electrical conductivity. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

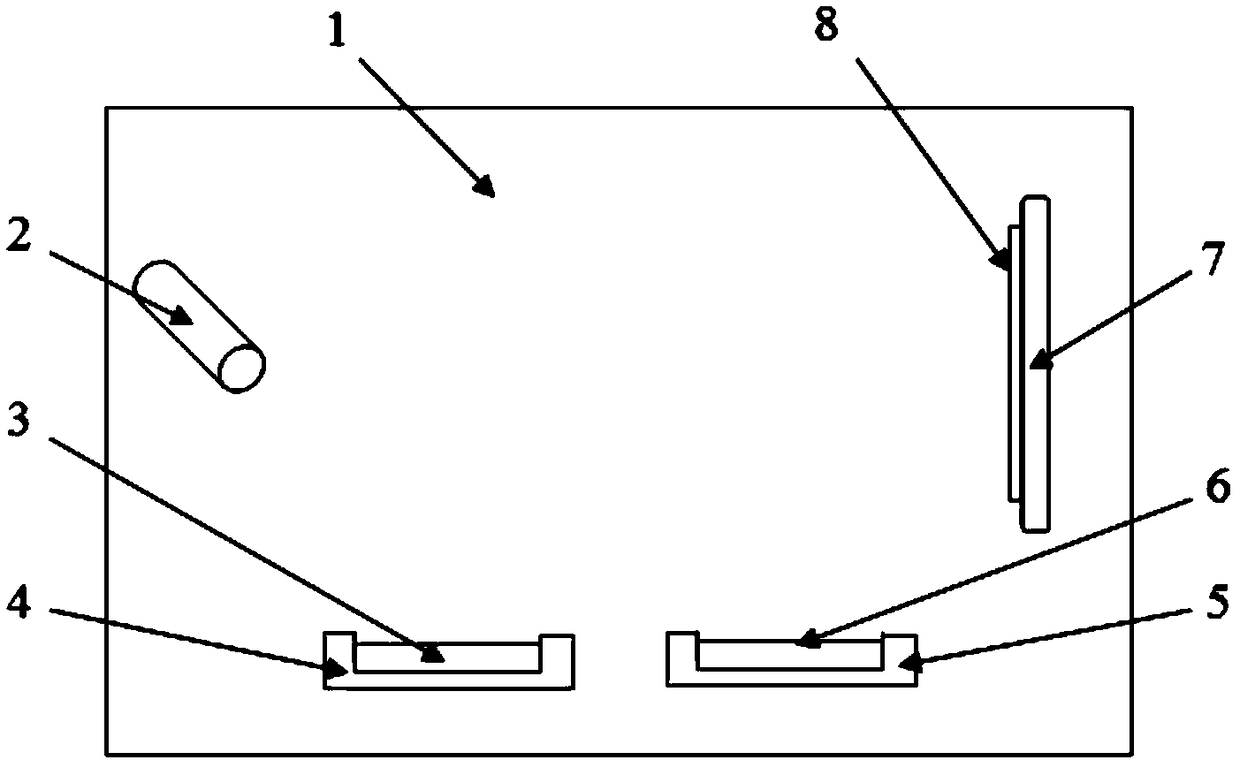

[0022] Example 1 Prepare a positive electrode sheet with a sulfur / carbon mass ratio of 7:3, a sulfur / carbon composite material thickness of 10 μm, and a desired shape and area

[0023] Before the sputtering operation starts, the aluminum foil 8 is cut into the required shape and area, and laid on the substrate holder 7 of the ion beam sputtering chamber 1 as a substrate, according to the sulfur target holder 4 and the carbon target holder 5 According to the specifications, cut and weigh the elemental sulfur block and elemental carbon block with a mass ratio of 7:3, and make the total amount of sulfur and carbon sufficient to deposit 10 μm thickness on the aluminum foil 8, and the obtained block sulfur 3 and block Bulk carbon 6 is respectively placed on the sulfur target support 4 and the carbon target support 5 as targets, and the ion beam sputtering chamber 1 is evacuated to 10 -4 Pa, using 100W power, emit an argon ion beam from the ion beam gun 2 to clean the surface of the...

Embodiment 2

[0025] Example 2 Prepare a positive electrode sheet with a sulfur / carbon mass ratio of 8:2, a sulfur / carbon composite material thickness of 60 μm, and a desired shape and area

[0026] Before the sputtering operation starts, the aluminum foil 8 is cut into the required shape and area, and laid on the substrate holder 7 of the ion beam sputtering chamber 1 as a substrate, according to the sulfur target holder 4 and the carbon target holder 5 According to the specifications, the elemental sulfur block and the elemental carbon block are cut and weighed at a mass ratio of 8:2, and the total amount of sulfur and carbon is sufficient to deposit a thickness of 60 μm on the aluminum foil 8, and the obtained block sulfur 3 and block Bulk carbon 6 is respectively placed on the sulfur target support 4 and the carbon target support 5 as targets, and the ion beam sputtering chamber 1 is evacuated to 10 -4 Pa, using 100W power, emit an argon ion beam from the ion beam gun 2 to clean the sur...

Embodiment 3

[0027] Example 3 Prepare a positive electrode sheet with a sulfur / carbon mass ratio of 9:1, a sulfur / carbon composite material thickness of 100 μm, and a desired shape and area

[0028] Before the sputtering operation starts, the aluminum foil 8 is cut into the required shape and area, and laid on the substrate holder 7 of the ion beam sputtering chamber 1 as a substrate, according to the sulfur target holder 4 and the carbon target holder 5 According to the specifications, cut and weigh the elemental sulfur block and the elemental carbon block with a mass ratio of 9:1, and make the total amount of sulfur and carbon sufficient to deposit 100 μm thickness on the aluminum foil 8, and the obtained block sulfur 3 and block Bulk carbon 6 is respectively placed on the sulfur target support 4 and the carbon target support 5 as targets, and the ion beam sputtering chamber 1 is evacuated to 10 -4Pa, using 100W power, emit an argon ion beam from the ion beam gun 2 to clean the surface o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com