Microchip transfer system and method

A chip transfer, miniature technology, used in electronic circuit testing, measuring devices, instruments, etc., to achieve the effect of reducing volume, enhancing magnetism, and reducing the risk of errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

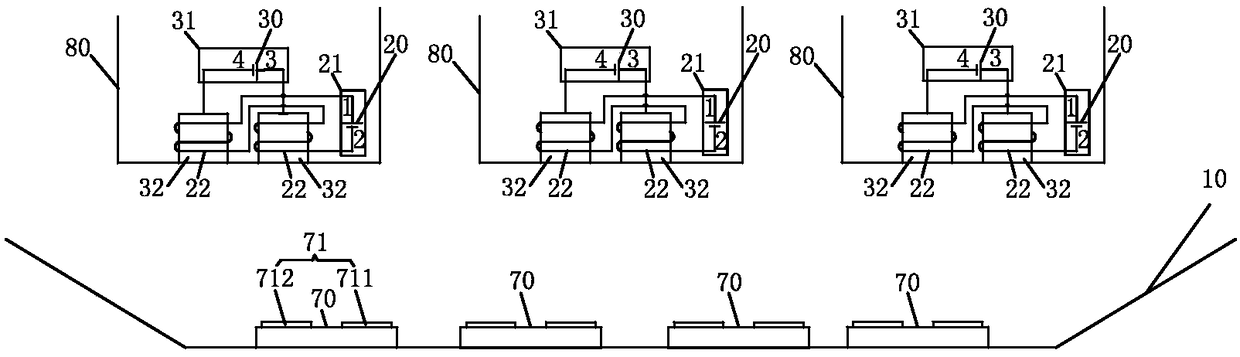

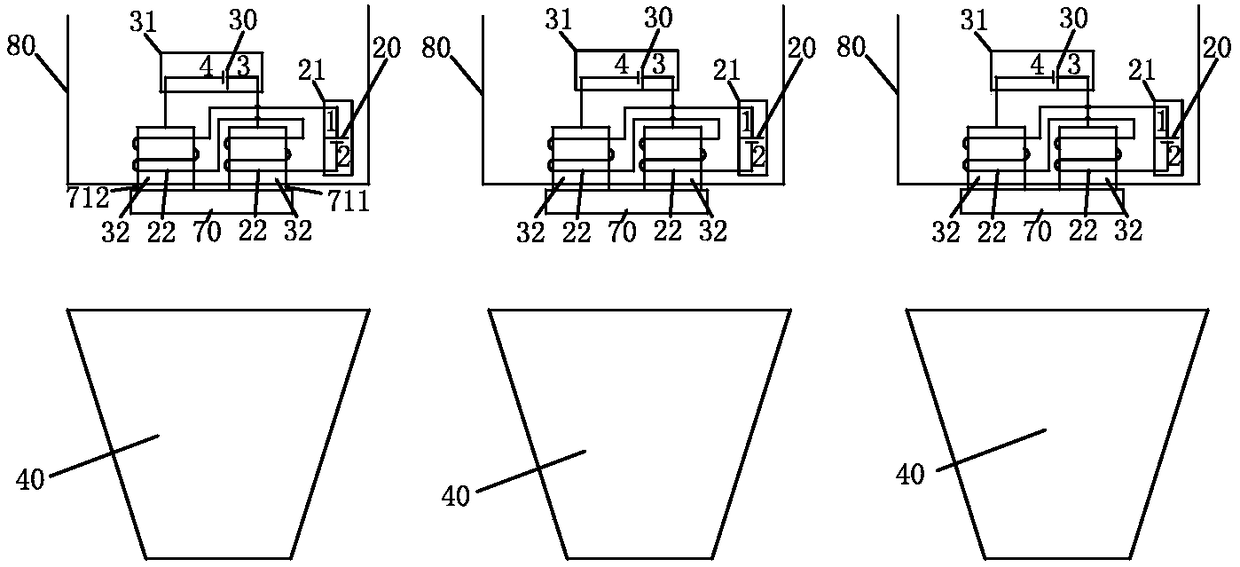

[0048] Such as figure 1 , 2, 3, 4, and 5, the microchip transfer system includes a storage device 10, a pick-up device, an electrical test device, an optical test device 40, a delivery device 50, a receiving device 60 and a carrier 80. The pick-up device and the electrical testing device are fixedly installed on the carrier 80 . In this embodiment, each carrier is provided with a pick-up device and an electrical testing device.

[0049] The storage device 10 is used for storing microchips 70 to be picked. The pick-up device is used to pick up the microchip 70 from the storage device 10 , or release the picked-up microchip 70 . The electrical testing device is used for testing the electrical performance of the microchip 70 picked up by the picking device. When the electrical testing device detects that the electrical performance of the microchip 70 picked up by the pick-up device is unqualified, the pick-up device will release the microchip 70 with unqualified electrical per...

Embodiment 2

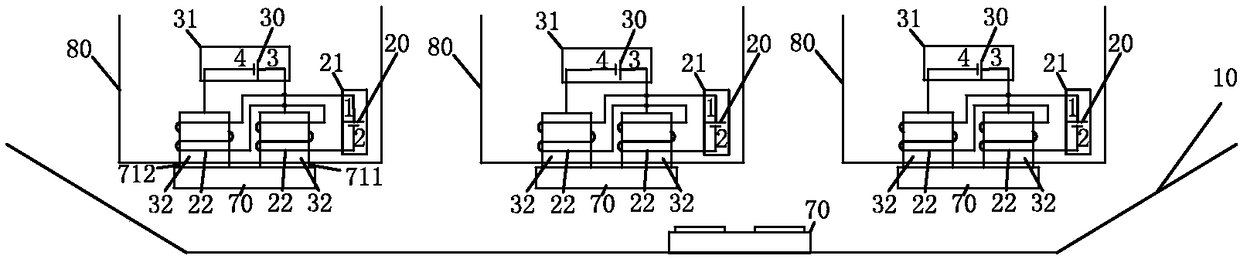

[0079] Such as Figure 7 As shown, the difference between this embodiment and the first embodiment is that the test electrode 32 of the electronic test device is not inserted into the solenoid 22 of the pick-up device. The magnetic suction nozzle of pick-up device comprises power circuit 21, solenoid 22 and the metal core 23 that inserts solenoid 22, and metal core 23 is made by metal material, as iron; Microchip 70 comprises two magnetic pins 72; Microchip The first chip electrode 711 and the second chip electrode 712 of 70 are not magnetic, and are not magnetic pins.

[0080] When the magnetic suction nozzle of the pick-up device attracts the magnetic pins 72 of the microchip 70 by magnetic force, the first chip electrode 711 and the second chip electrode 712 of the microchip 70 are respectively connected with the two test electrodes 32 of the electronic testing device. The electrical performance of the microchip 70 picked up by the pick-up device can be tested without posi...

Embodiment 3

[0088] The difference between this embodiment and the first embodiment is that the distribution device 50 is a mechanical arm capable of translation and flipping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com