Embedded type superficial layer combination drainage pipe and construction method

A construction method and drainage pipe technology, applied in infrastructure engineering, construction, etc., can solve the problems of complex process, large manpower, machinery, and high cost, and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

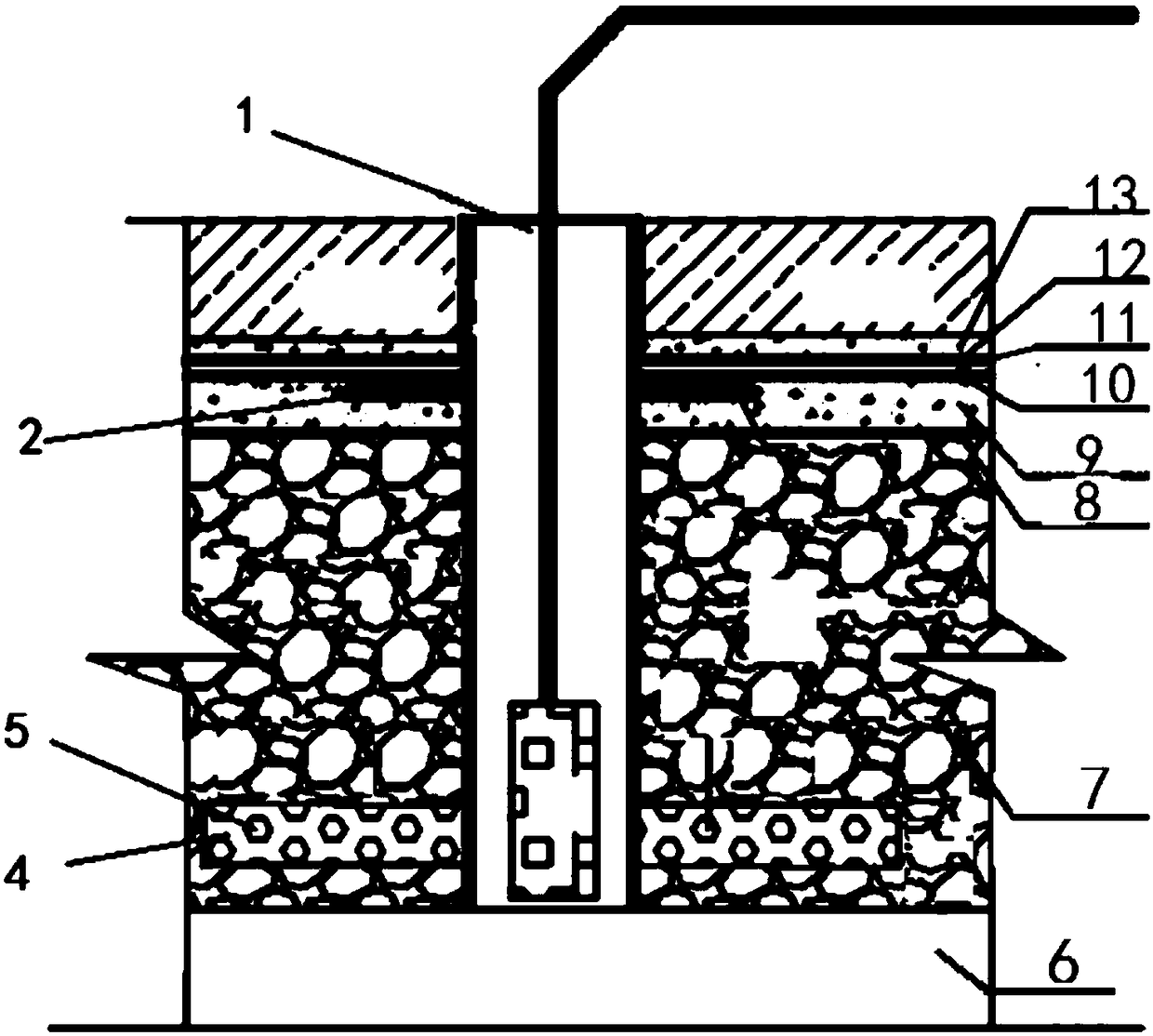

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

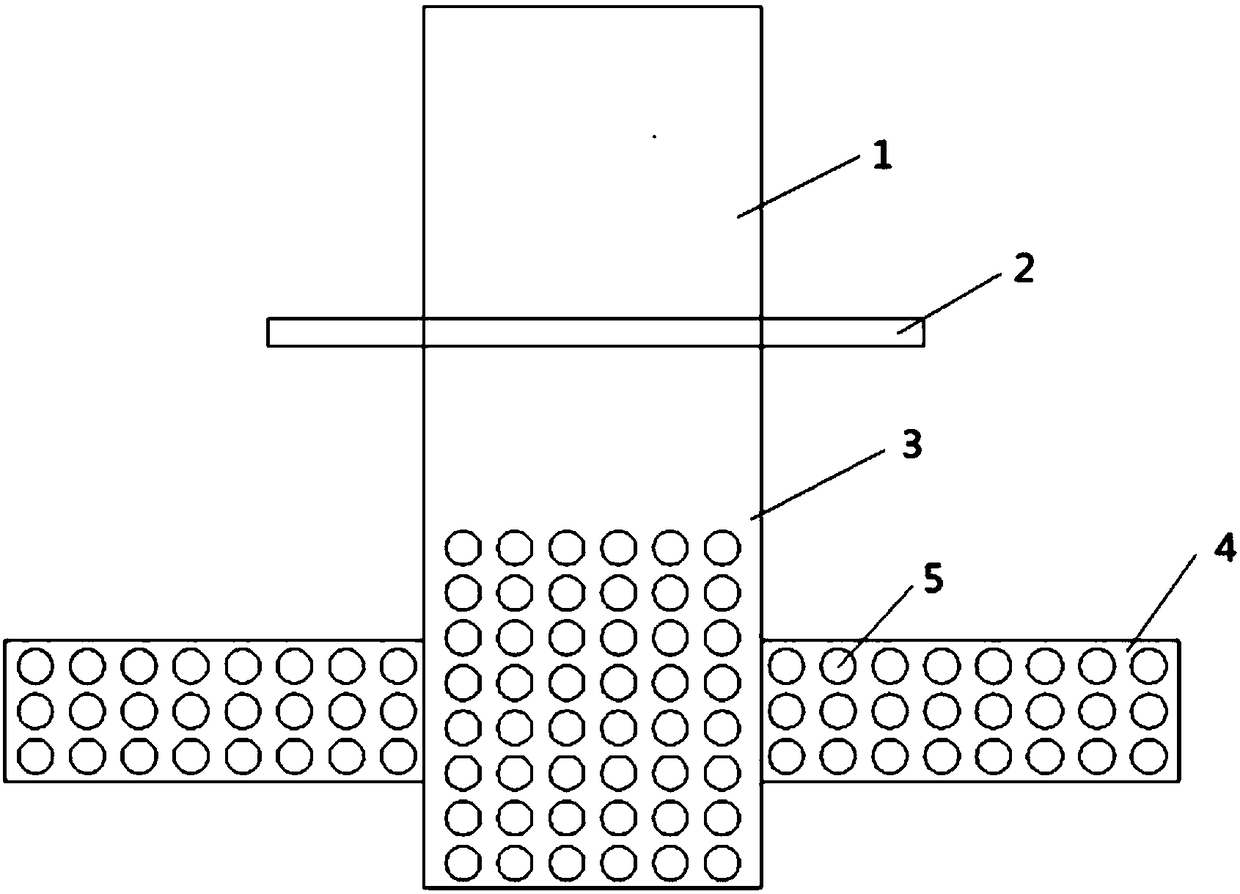

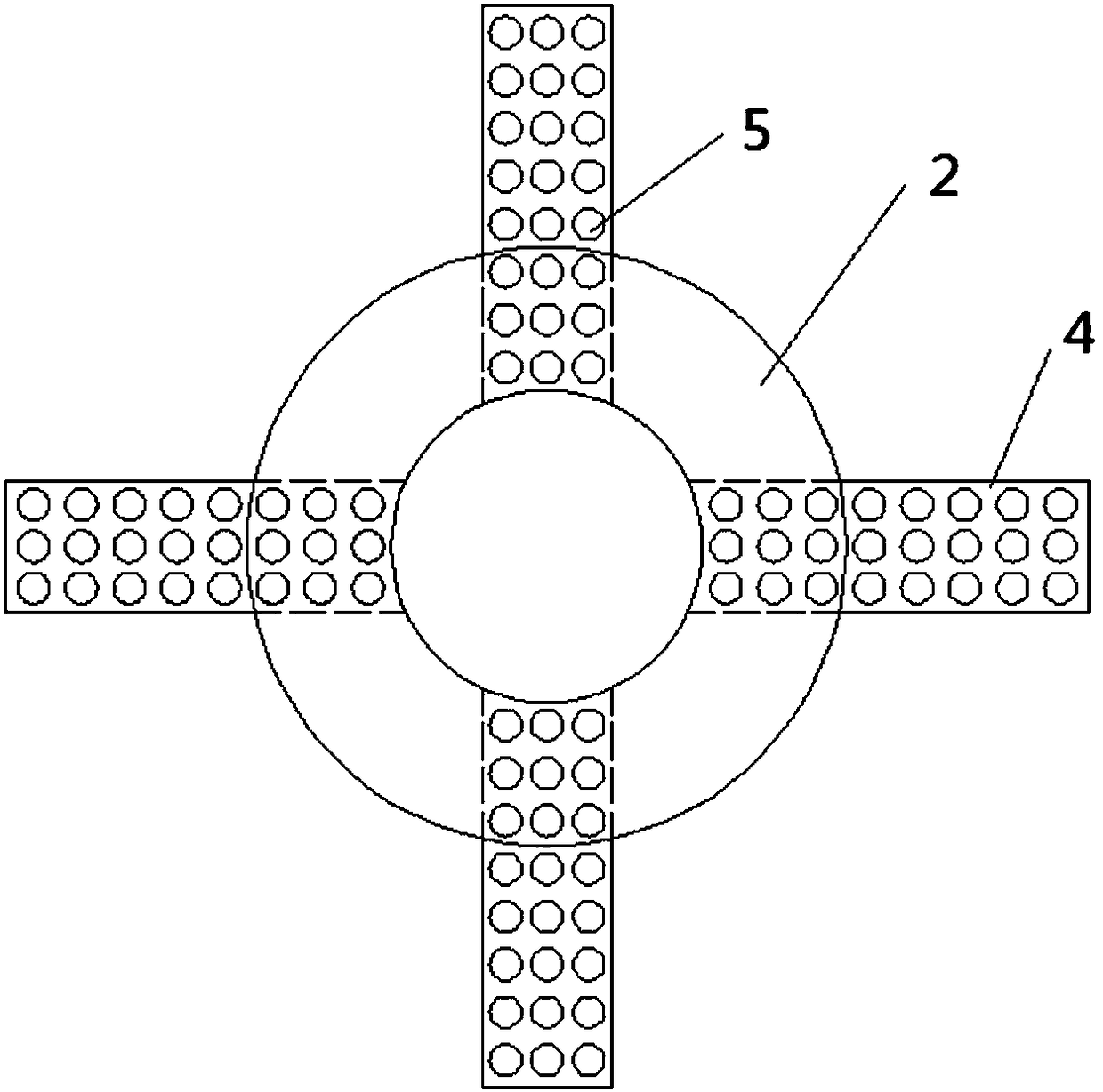

[0037] like figure 1 and 2 As shown, an embedded shallow composite drainage pipe includes a well pipe 1, a water stop ring 2, a water filter well main pipe 3, a water filter well branch pipe 4, and a water filter hole 5.

[0038] Wherein, the water filter well main pipe 3 is vertically pre-buried at the bottom of the sump in the foundation pit, the water filter well main pipe 3 is a barrel-packed structure with a closed bottom, and a plurality of water filter holes 5 are arranged on the side wall of the water filter well main pipe 3 to prevent water seepage. The seepage water in the pit enters in the water filter well main pipe 3 through the water filter hole 5, and the diameter of the water filter well main pipe 3 is determined and adjusted according to the seepage area and the water v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com