Gold coin manufacturing process, gold coin and clock

A manufacturing process and technology of gold coins, applied in the field of minting technology, can solve the problems of single luster of gold coins, achieve high value, enhance visual effects and sense of value, and enhance market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

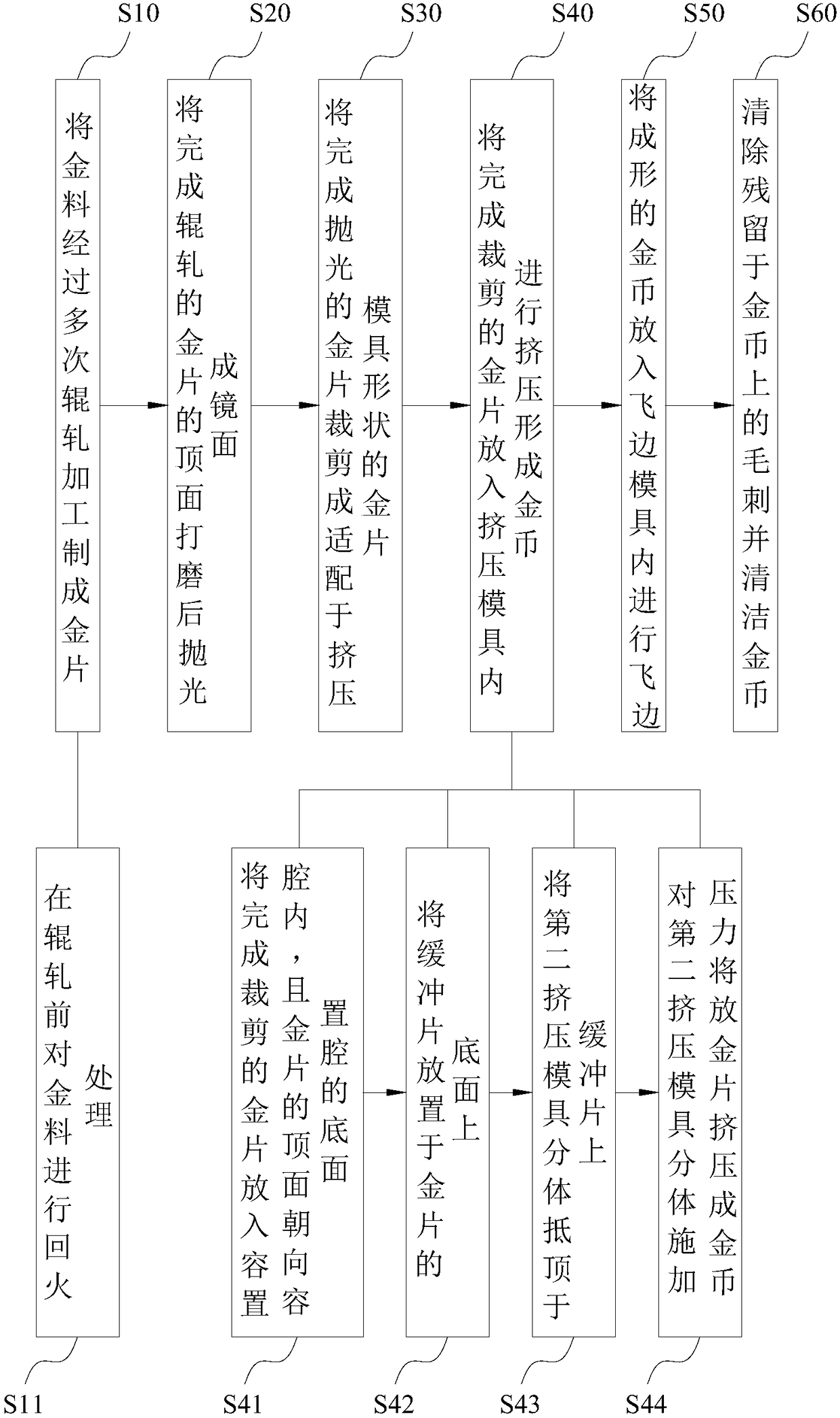

[0050] Further, see figure 1 , as a specific implementation of the gold coin manufacturing process provided by the present invention, the above step S40 specifically includes the following steps:

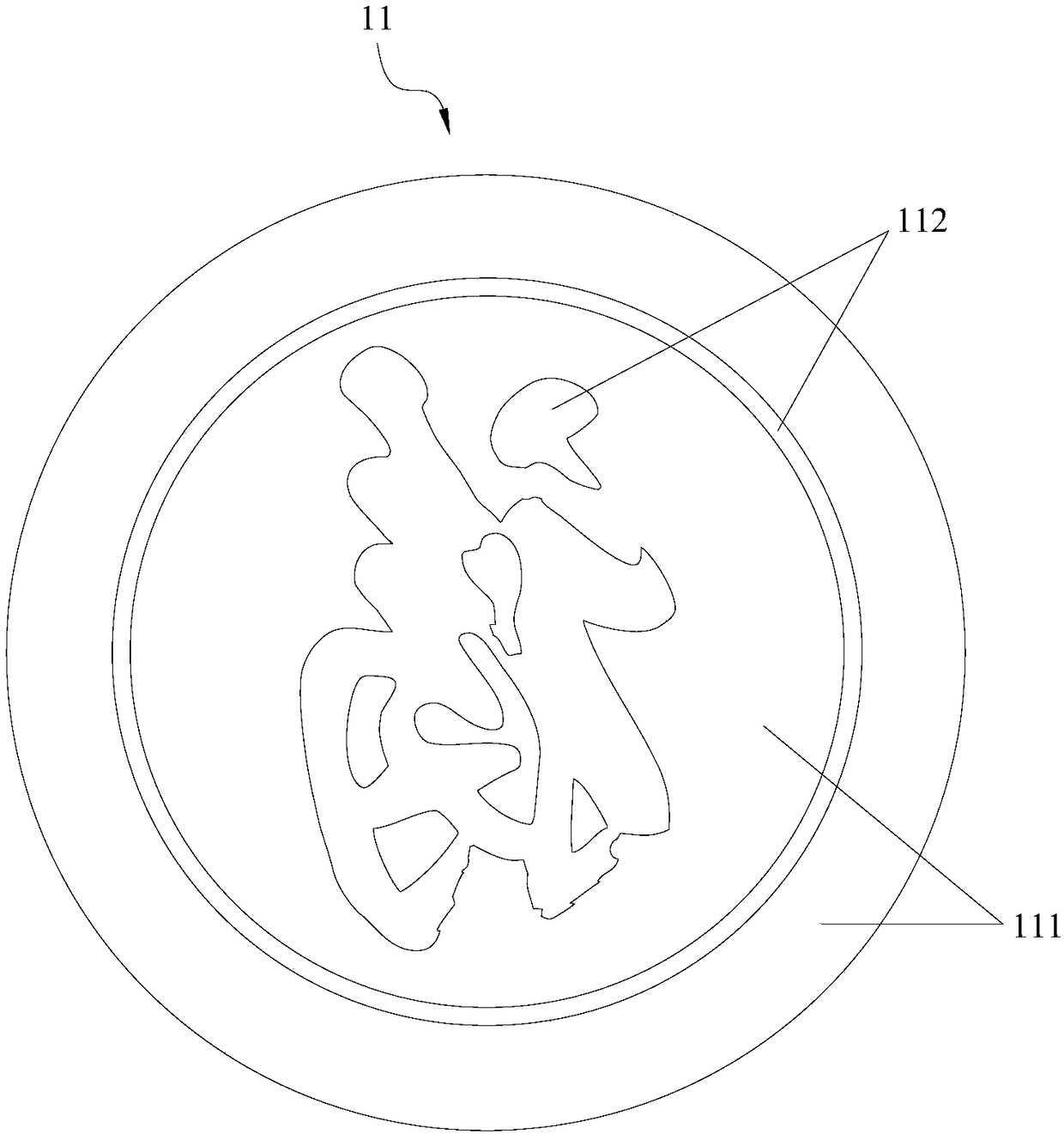

[0051] S41. Put the cut gold piece into the above-mentioned accommodating cavity 111, and the top surface of the gold piece faces the bottom surface of the accommodating cavity 111;

[0052] S42, placing the buffer sheet on the bottom surface of the gold sheet;

[0053] S43, splitting the second extrusion die against the buffer sheet;

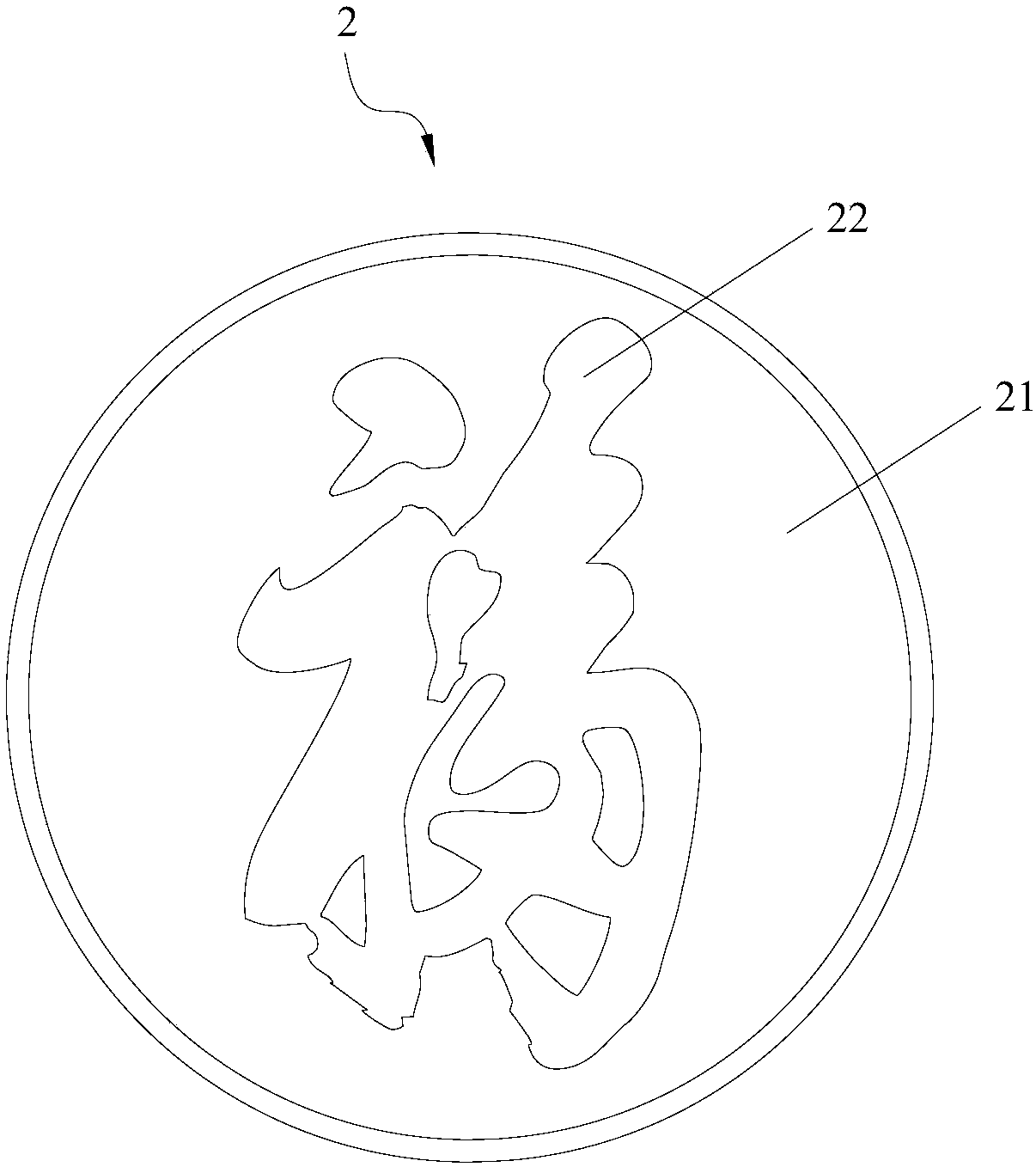

[0054] S44. Apply pressure to the second extrusion die to extrude the gold sheet into gold coins 2 .

[0055] Specifically, in step S40, the above-mentioned extrusion die is first installed on the hydraulic press, the first extrusion die split 11 is fixed on the hydraulic press workbench, the second extrusion die split is installed on the hydraulic press slider, and then the completed The top surface of the cut gold sheet faces the bottom surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com