Preparation method and application of a kind of bismuth nanosheet with controllable thickness and its alloy

A bismuth nanometer and bismuth chloride technology is applied in the field of preparation of bismuth nanosheets and their alloys, which can solve the problems of low efficiency, high overpotential, poor stability and the like, and achieves simple process flow, low overpotential and environmental friendliness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A method for preparing bismuth nanosheets with controllable thickness provided by the invention comprises the following steps:

[0040] The bismuth nanosheets are prepared by using bismuth salt compounds as raw materials and ethylene glycol ether as a solvent through aqueous solution reduction.

[0041] A specific scheme of a method for preparing bismuth nanosheets with controllable thickness is as follows:

[0042]Add 0.5 mmol-5 mmol bismuth salts to 200-300 mL ethylene glycol ether, stir ultrasonically until the solution becomes transparent, then stir the reaction at 25-120 °C for 30-60 hours under the protection of inert gas min, after cooling to room temperature, add 20-40 mmol NaBH dropwise in an atmosphere of inert gas 4 or LiBH 4 The reducing solution was stirred and reacted for 15-30 min. After the reaction was completed, it was sonicated, filtered with ethanol and water, washed, collected, and dried to obtain bismuth nanosheets. Preferably, the thickness of ...

Embodiment 1

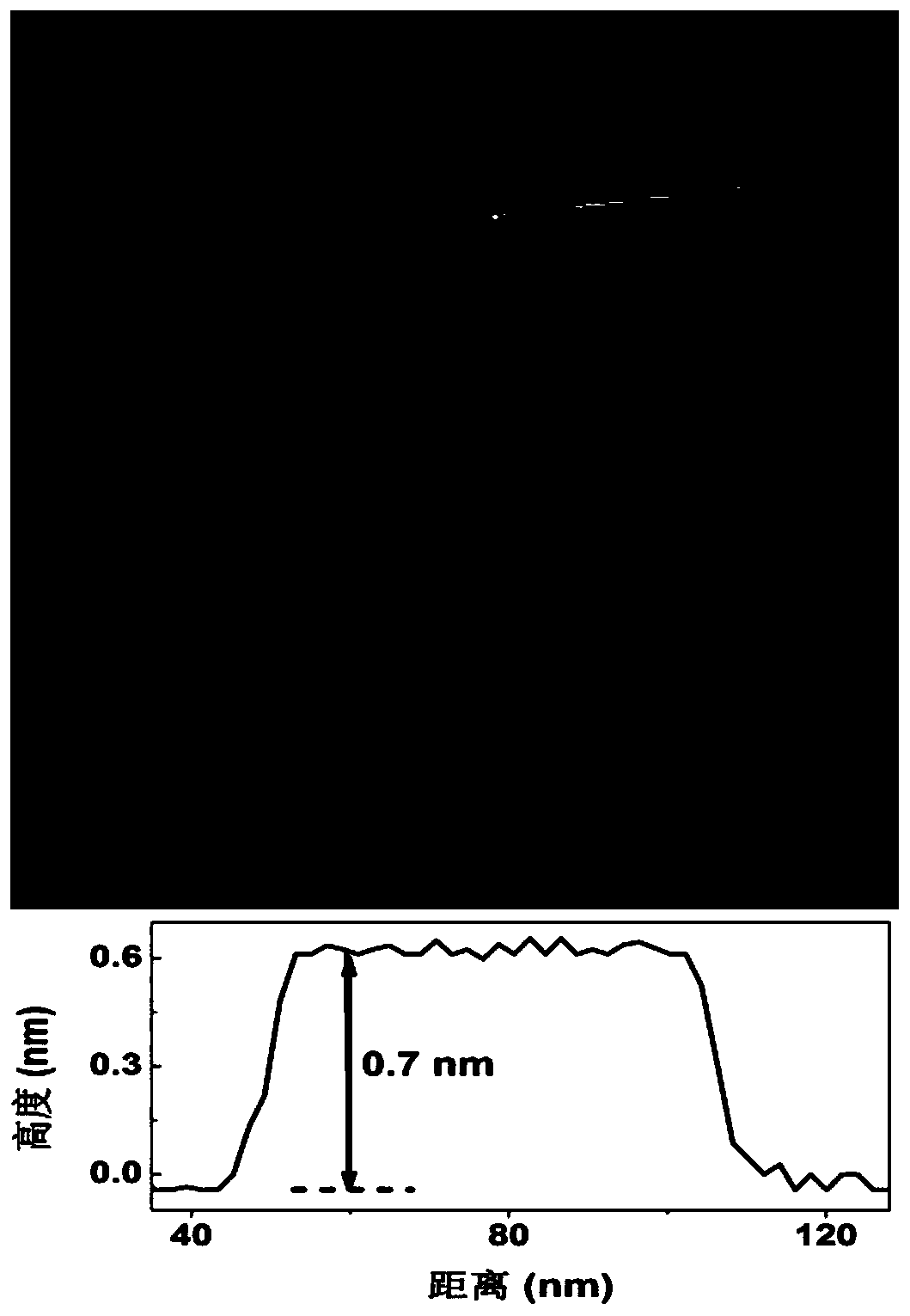

[0049] Preparation of Bismuth Nanosheets with a Thickness of 0.7 nm

[0050] Add 0.5 mmol of bismuth chloride to 200 mL of ethylene glycol ether, stir until the solution becomes transparent, then stir and react at 25 °C for 30 min under the protection of an inert gas, cool to room temperature, and Add 20 mmol NaBH dropwise in the atmosphere 4 The reducing solution was stirred and reacted for 15 min. After the reaction, it was ultrasonicated, filtered with ethanol and water, washed, collected, and dried to obtain bismuth nanosheets with a thickness of 0.7 nm.

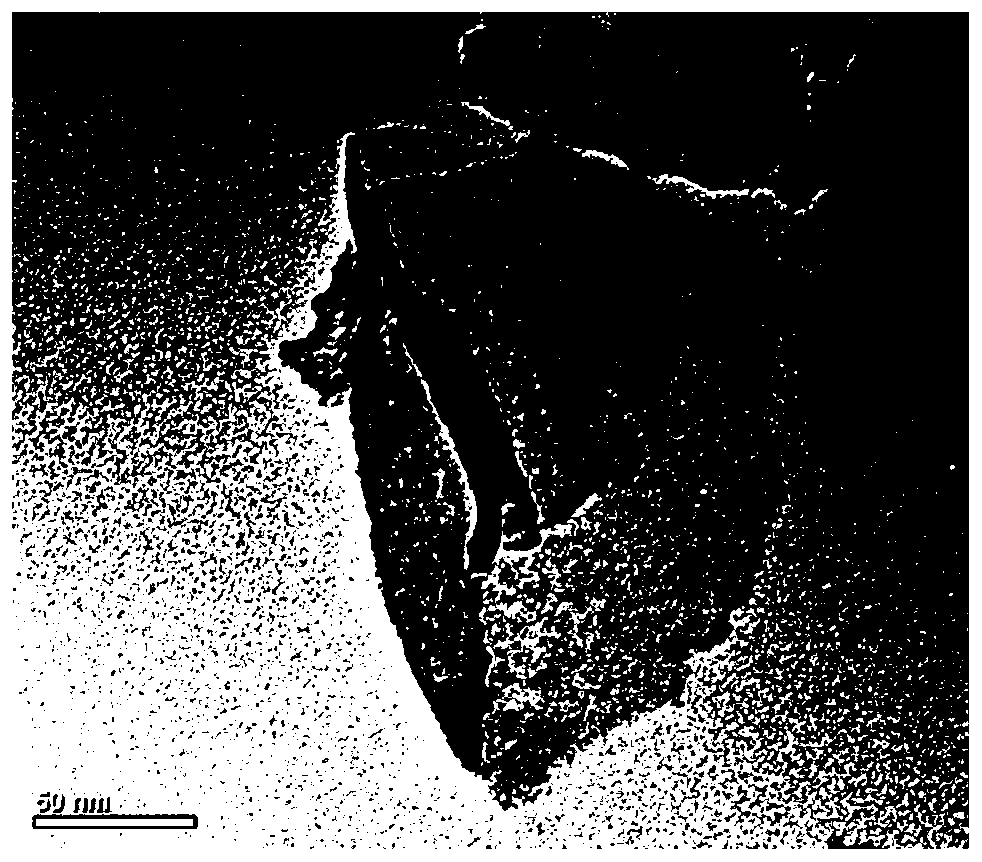

[0051] figure 1 It is a transmission electron microscope image of the bismuth nanosheets prepared in Example 1 of the present invention. It can be seen from this image that the bismuth nanosheets prepared in this example present an ultrathin sheet structure.

[0052] figure 2 Atomic force microscope image of the bismuth nanosheets prepared in Example 1 of the present invention; it can be seen from the image that its ...

Embodiment 2

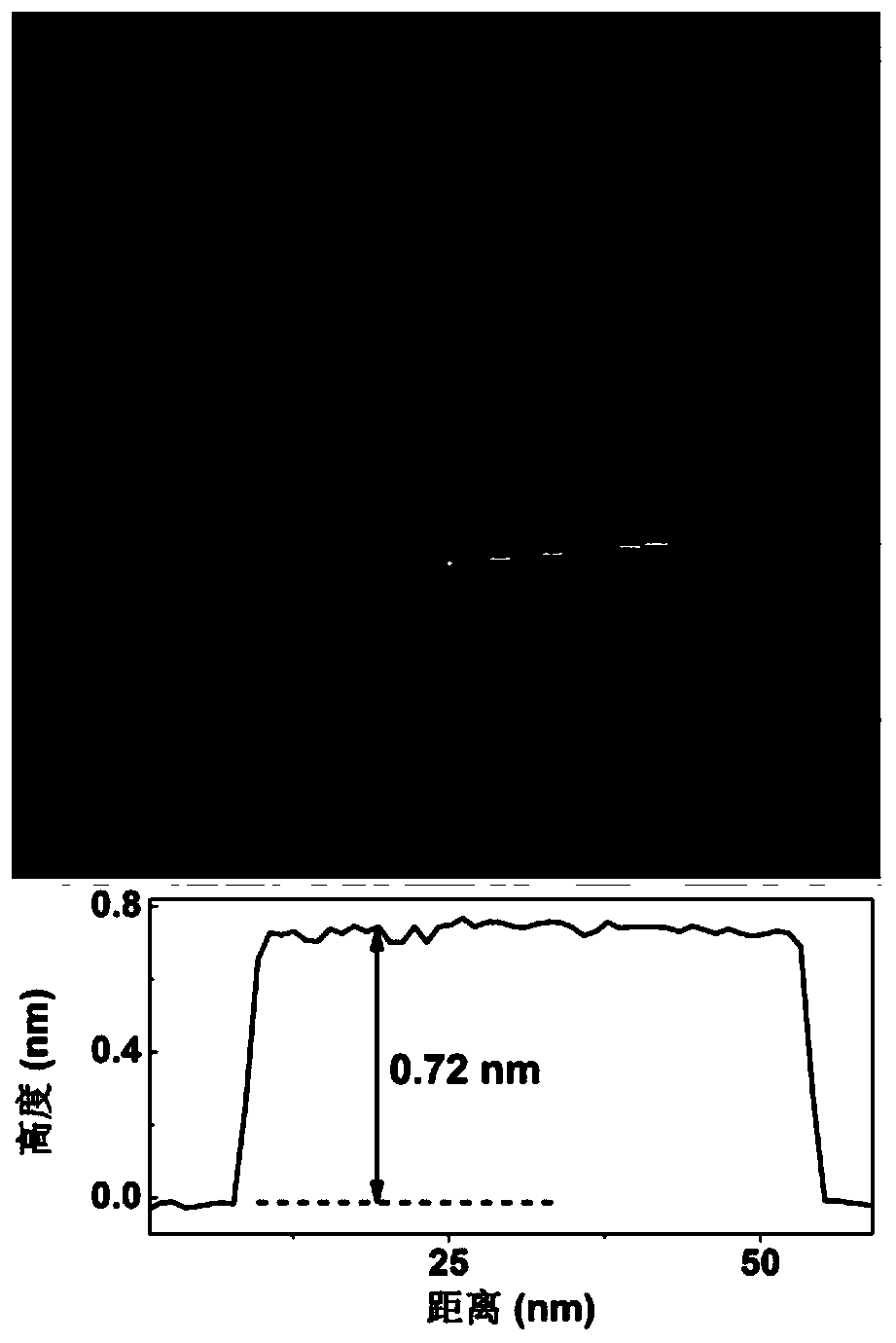

[0058] Preparation of bismuth nanosheets with a thickness of 4 nm

[0059] Add 2.5 mmol of bismuth nitrate compound into 250 mL of ethylene glycol ethyl ether, stir ultrasonically until the solution becomes transparent, then stir and react at 70 °C for 45 min under the protection of an inert gas, cool to room temperature, and Add 30 mmol LiBH dropwise in the atmosphere 4 The reducing solution was stirred and reacted for 20 min. After the reaction, it was ultrasonicated, filtered with ethanol and water, washed, collected, and dried to obtain bismuth nanosheets with a thickness of 4 nm.

[0060] Figure 4 The atomic force microscope image of the bismuth nanosheets prepared in Example 2 of the present invention, it can be seen from the figure that the thickness of the bismuth nanosheets is 4 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com