An integrated forging and testing production line for gear parts and its working method

A production line and parts technology, applied in the field of integrated forging and testing production lines, can solve problems such as uncertain errors, low sorting efficiency, and obstacles to fully automatic production lines, and achieve adjustable horizontal positions, reliable grasping methods and Convenience and the effect of saving testing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

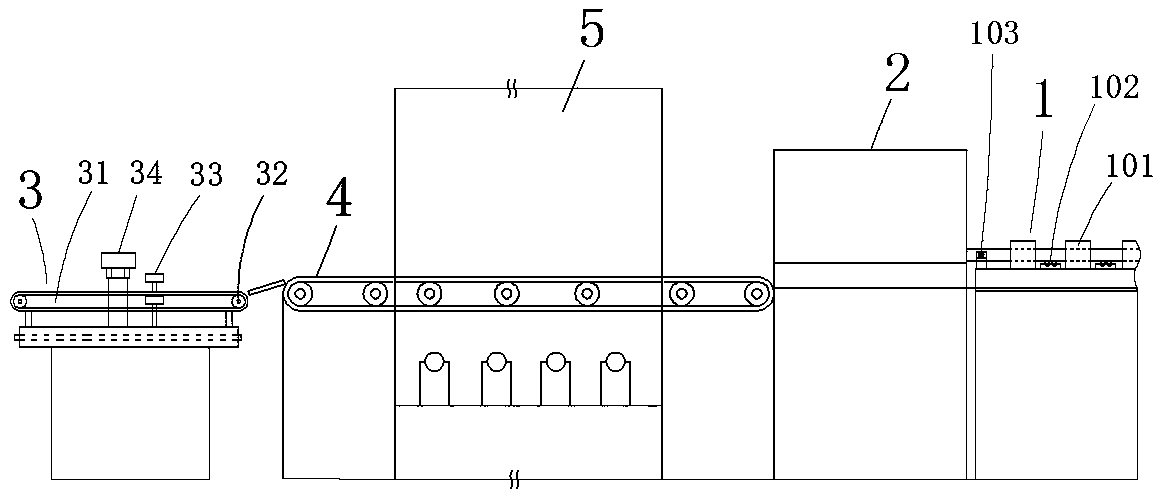

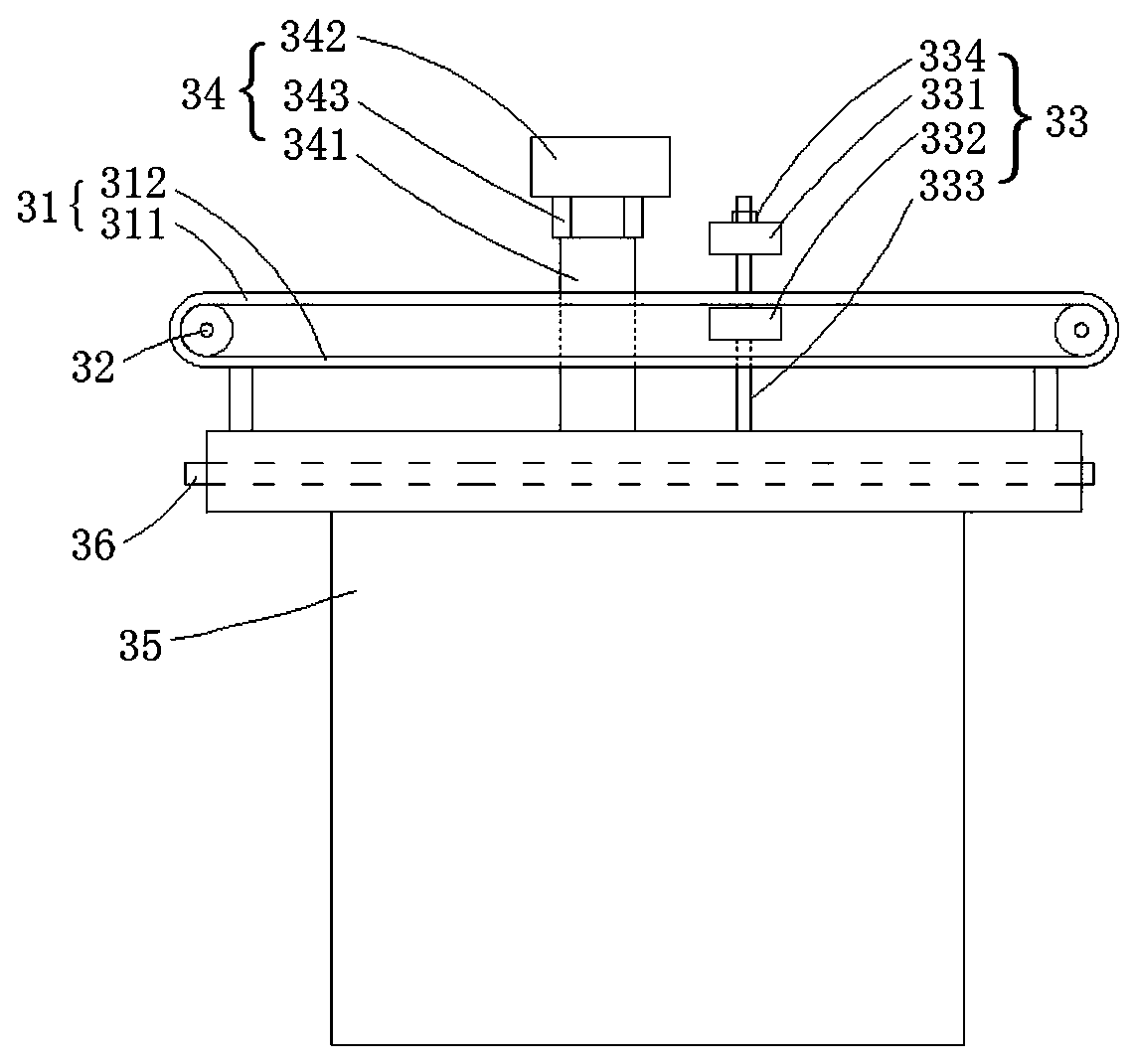

[0029] An integrated forging and testing production line for gear parts of the present invention, such as Figure 1 to Figure 3 As shown, it includes a heating furnace device 1, a forging die 2, a heat treatment device 5 and a sorting device 3 arranged in sequence. The discharge port of the mold 2 is docked, and the other end is docked with the feed port of the sorting device 3. The sorting device 3 is provided with an observation carrier 31, and the edge of the observation carrier 31 is provided with a carrier transmission device 32, so The observation platform 31 moves circularly under the drive of the platform transmission device 32 , and a detection device 33 and a sorting manipulator 34 are arranged on one side of the observation platform 31 .

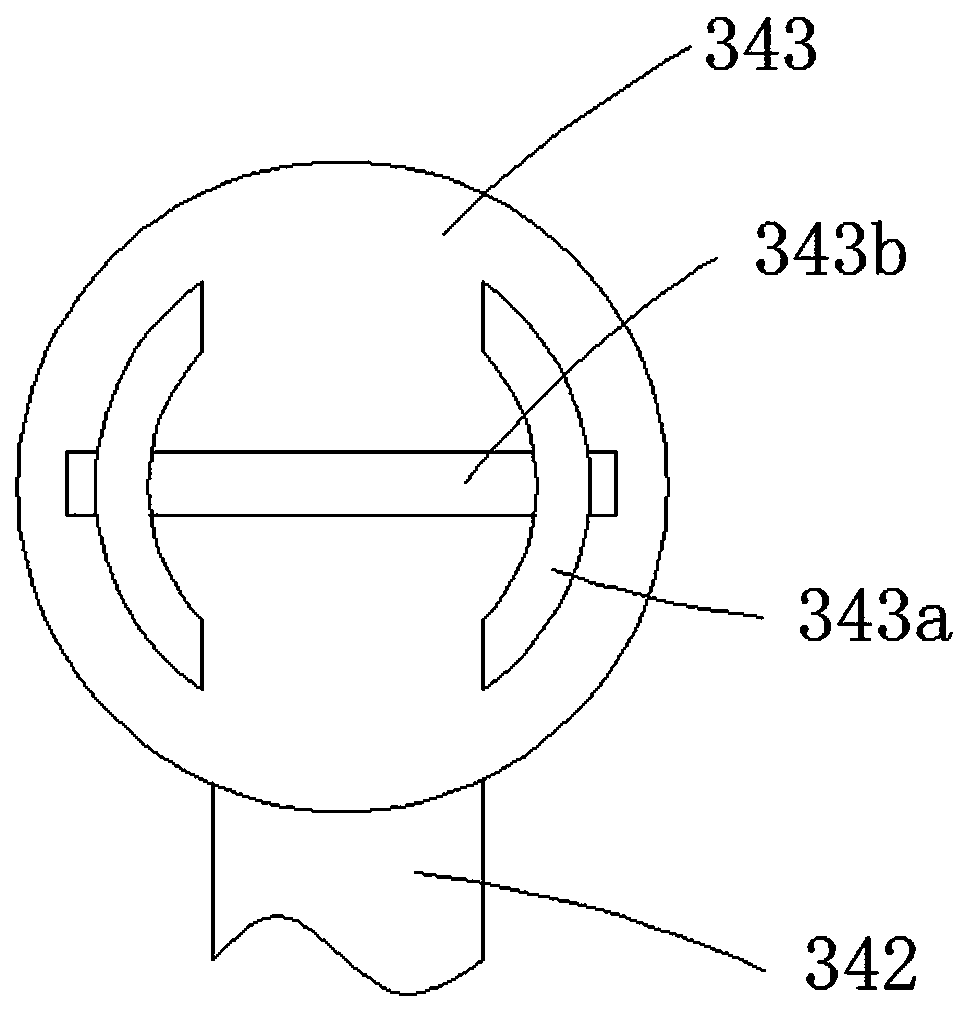

[0030] In this embodiment, the observation platform 31 includes a transparent upper loading platform 311 and a lower loading platform 312 , and the detection device 33 includes an upper detection device 331 and a lower detection d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com