Logistics sorting system

A sorting system and logistics technology, applied in logistics, sorting, instruments, etc., can solve the problems of waste of materials, rising hardware costs, difficulties, etc., and achieve the effect of improving sorting efficiency, reducing error rate, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

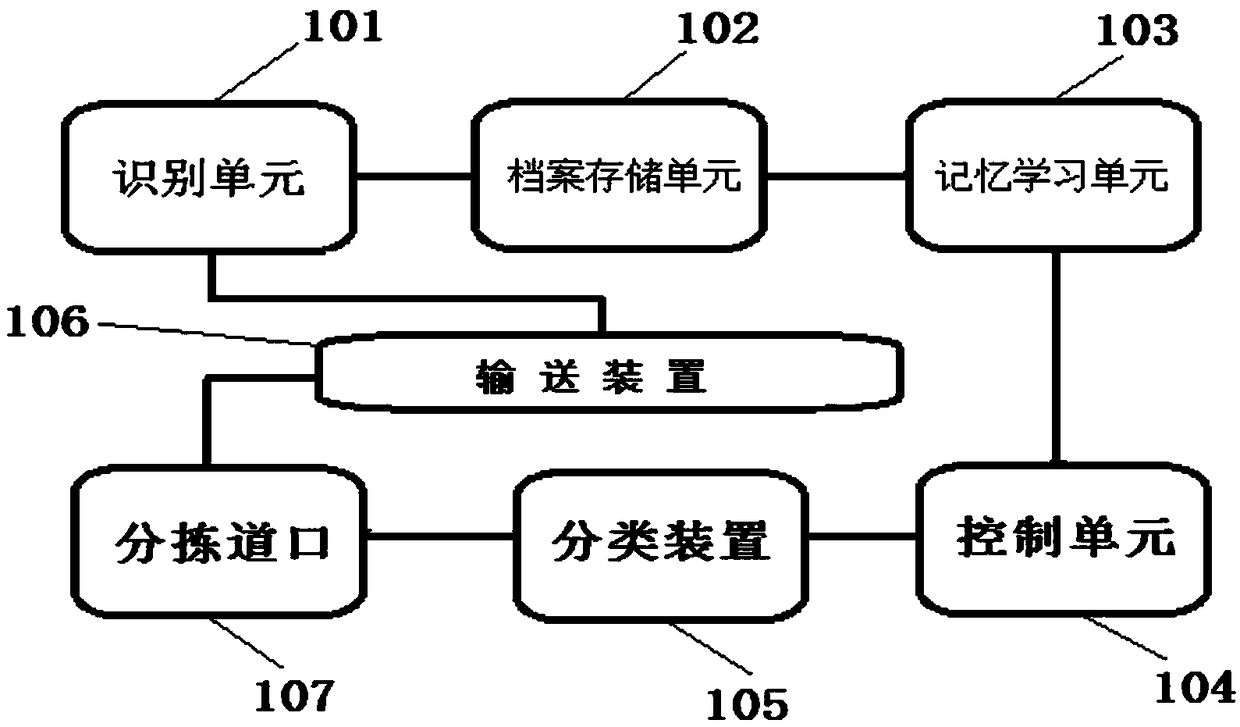

[0036] Depend on Figures 1 to 2 As shown, a logistics sorting system includes: an identification unit 101, a file storage unit 102, a memory learning unit 103, a control unit 104, a classification device 105, a conveying device 106, and a sorting crossing 107;

[0037] Further, the identification unit 101 includes: a three-dimensional scanning probe and an acquisition and identification system, which are used for three-dimensional scanning of the items on the conveying device, quickly classifying the information, and sending it to the file storage unit in real time for data processing;

[0038] As an example, the three-dimensional scanning probe can process information in two-dimensional codes and barcodes for rapid identification;

[0039] As an example, the three-dimensional scanning probe includes two scanning probes arranged in the hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com