Pulsating type atomizer

A technology of atomizer and atomization medium, which is applied in the direction of burners, injection devices, injection devices, etc., can solve the problems of inapplicability, complex design and operation control, etc., to improve combustion efficiency, enhance heat transfer, and promote mixing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

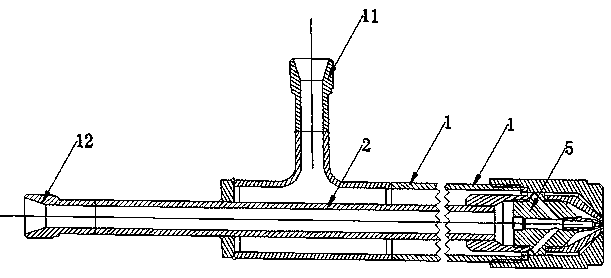

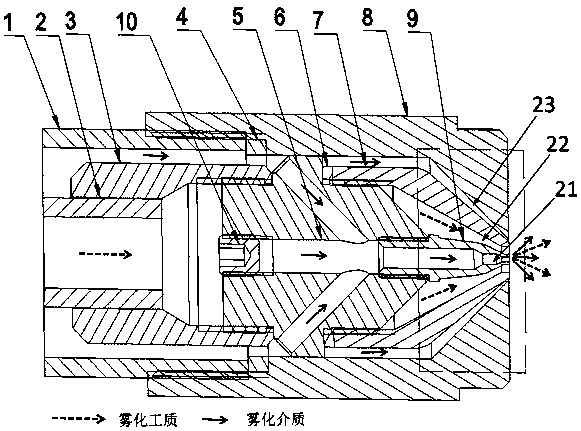

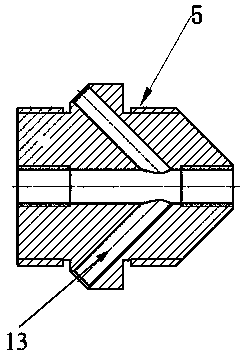

[0028] Such as figure 1As shown, a pulsating atomizer includes a conveying pipeline and an atomizing nozzle, and the conveying pipeline includes a nested outer pipeline and an inner pipeline, wherein: the outer pipeline is an atomizing medium pipeline 1 for passing through the atomizing medium ( Such as air, oxygen, etc.), the atomizing medium pipeline 1 is designed with an atomizing medium interface 11, and the atomizing medium source pipeline is connected through the atomizing medium interface 11; the inner pipeline is the atomizing substance pipeline 2, which is used to flow through the atomizing medium (such as water, light oil, heavy oil, coal water slurry, etc.), one end of the atomizing chemical pipeline 2 is designed as an atomizing chemical interface 12, through which the atomizing chemical interface 12 is connected to the source pipeline of the atomizing chemical, and the atomizing chemical interface 12 is located at the The outside of the atomizing medium pipeline 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com