A linkage type multi-stage sewage purification device

A sewage purification and purification device technology, applied in chemical instruments and methods, fixed filter element filters, separation methods, etc., can solve the problems of unsatisfactory sewage treatment effect, reduce purification efficiency, increase purification cost, etc., and prolong the use time , Improve the purification efficiency and accelerate the discharge speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

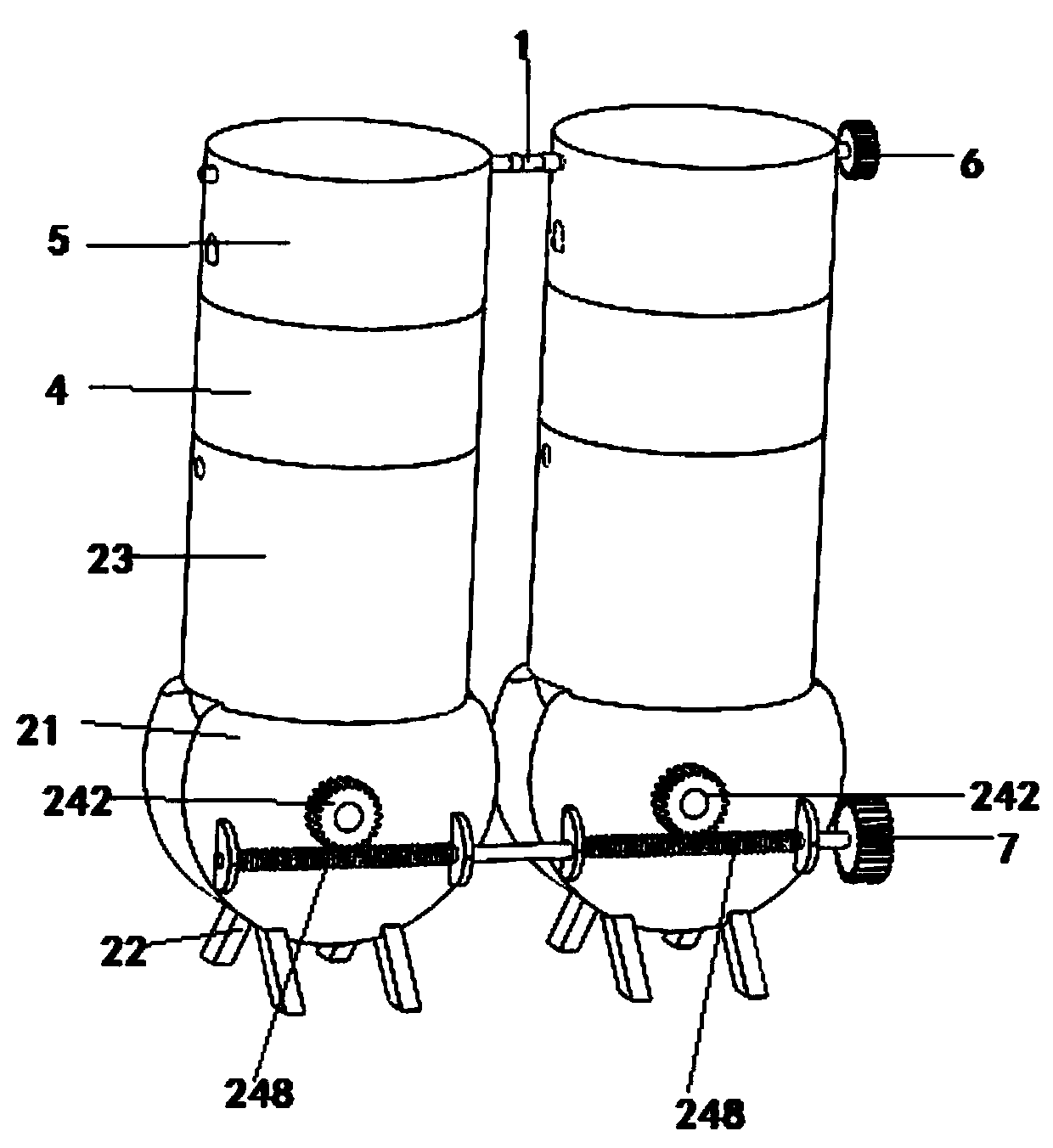

[0033] A linkage type multi-stage sewage purification device, such as figure 1 As shown, it includes a number of step-by-step purification devices connected by couplings 1, wherein the step-by-step purification devices include successively connected primary purification devices and secondary purification devices, wherein the primary purification device and the secondary purification device have the same structure, Through a number of step-by-step purification devices, the step-by-step purification of sewage can be achieved, and then the standard of domestic water can be reached;

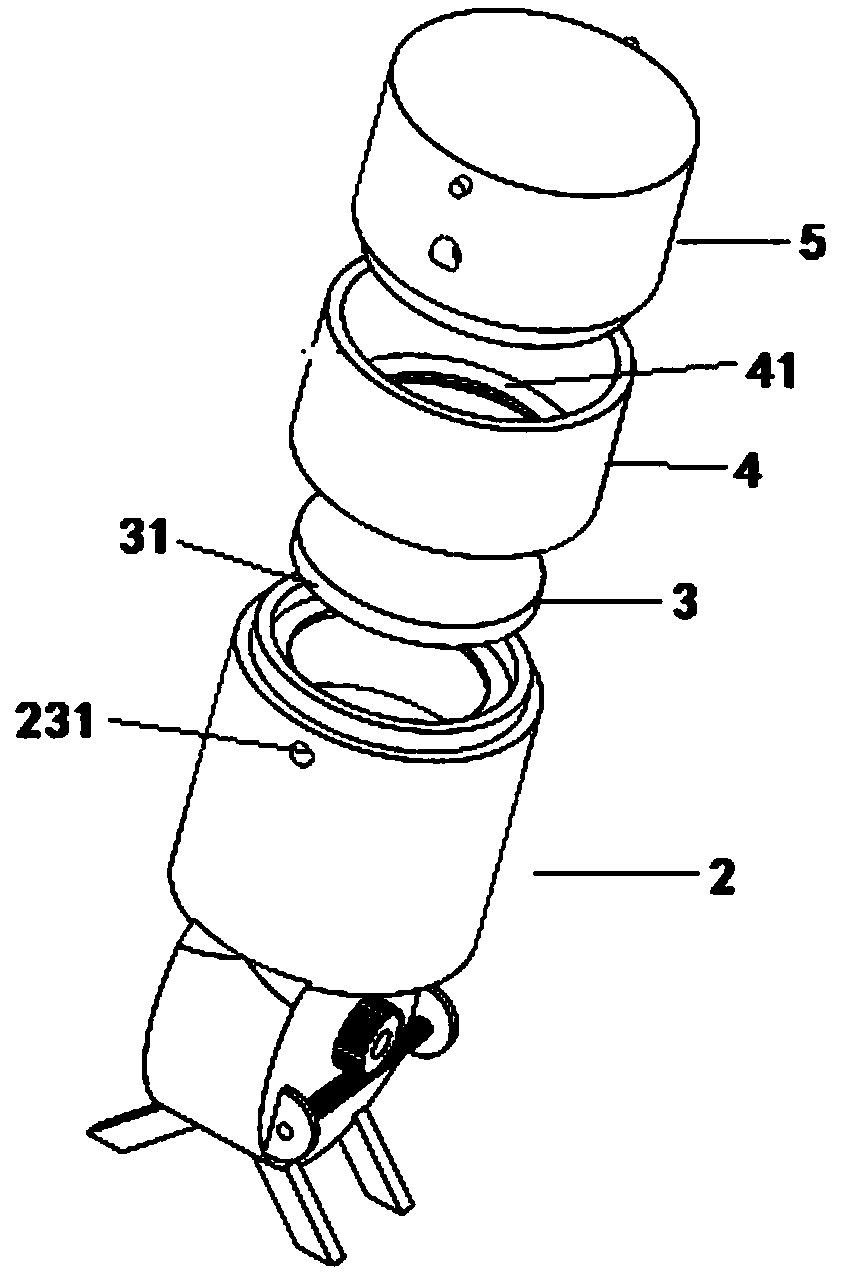

[0034] like figure 2 As shown, the primary purification device includes a flushing seat 2, a purification assembly 3, a buffer storage tank 4 and an inlet and outlet valve seat 5 that are sleeved and connected sequentially from bottom to top;

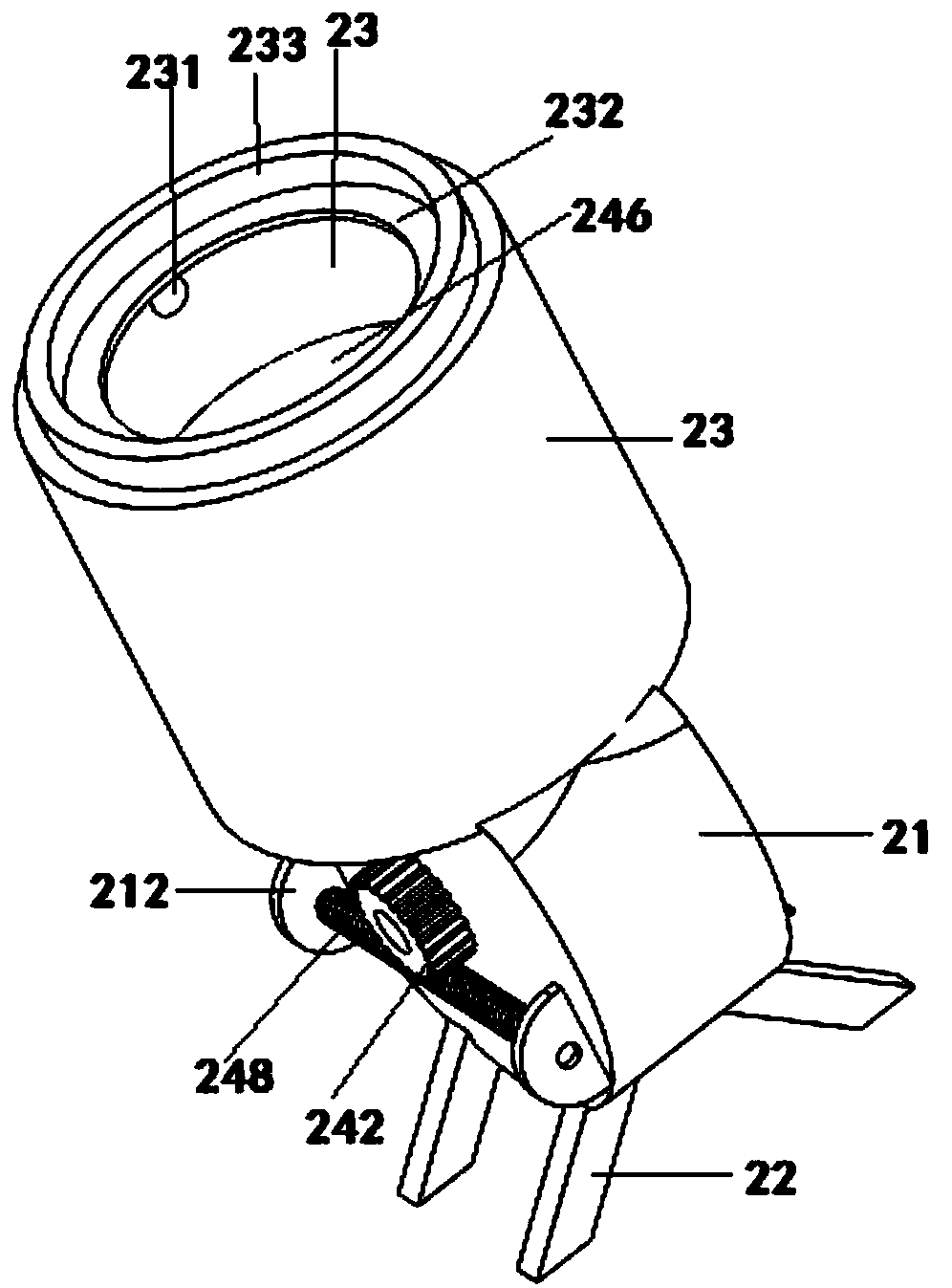

[0035] like image 3 , Figure 4 , Figure 5 , Image 6 and Figure 7 As shown, the flush seat 2 includes a power transmission seat 21, the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com