Resin composition and multilayer structure using same

A technology of resin composition and copolymer, which is applied in the direction of synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve the problems of multilayer structure appearance (transparency reduction, roughness, etc.), and achieve the suppression of interface roughness The effect of improving the appearance of the poor appearance and the deterioration of the color tone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

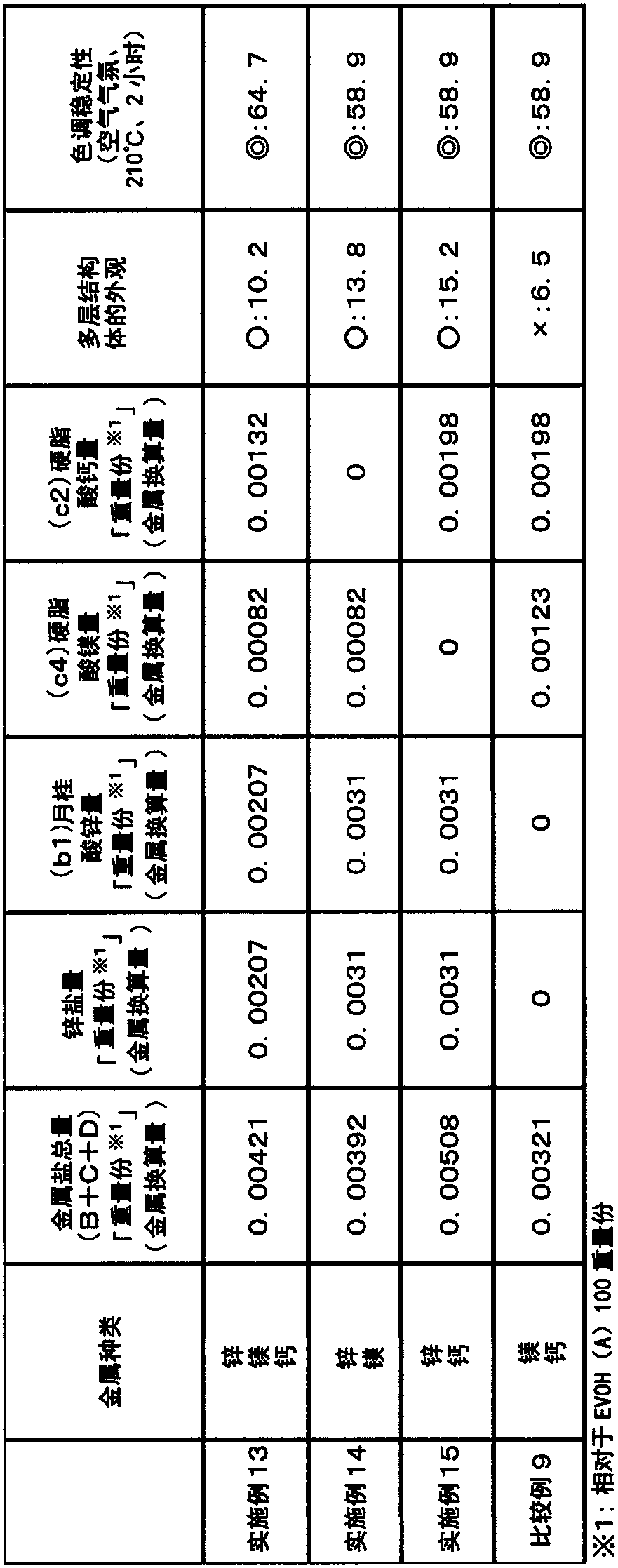

Examples

Embodiment 1

[0156]

[0157] As EVOH (A), use EVOH (a1) [content of ethylene structural unit 38 mol%, degree of saponification 99.6 mol%, MFR 4.2g / 10min (210°C, load 2160g)] pellets, as carbon number 3-12 Fatty acid metal salt (B), using 0.0017 parts of zinc laurate (b1) in terms of metal relative to 100 parts of EVOH (a1), as a fatty acid metal salt (C) with 13 to 20 carbon atoms, using (a1) 100 parts of zinc stearate (c1) which is 0.0012 parts in terms of metal, used as a fatty acid metal salt (D) having 21 to 29 carbon atoms, 0.0011 parts in terms of metal relative to 100 parts of EVOH (a1) parts of zinc behenate (d1). After dry mixing EVOH (a1) pellets, zinc laurate (b1), zinc stearate (c1) and zinc behenate (d1), use a 20mmφ twin-screw extrusion molding device (L / D=25 ) was melt-kneaded and pelletized again to prepare the resin composition of the present invention.

[0158]

[0159] The resin composition prepared above, linear low-density polyethylene (LLDPE) (manufactured by Ni...

Embodiment 2

[0183] In Example 1, 0.0025 parts of zinc laurate (b1) in terms of metal relative to 100 parts of EVOH (a1) and 0.0025 parts of zinc stearate ( c1) and 0.0025 parts of zinc behenate (d1) in terms of metal relative to 100 parts of EVOH (a1) were carried out in the same manner to produce a resin composition and a multilayer structure. The appearance of the obtained multilayer structure and the color tone stability of the resin composition were evaluated in the same manner as in Example 1.

Embodiment 3

[0185] In Example 1, 0.00333 parts of zinc laurate (b1) in terms of metal relative to 100 parts of EVOH (a1) and 0.00333 parts of zinc stearate ( c1) and 0.00333 parts of zinc behenate (d1) in terms of metal relative to 100 parts of EVOH (a1) were carried out in the same manner to produce a resin composition and a multilayer structure. The appearance of the obtained multilayer structure and the color tone stability of the resin composition were evaluated in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com