Integrated sensor for bioelectrode and method for production

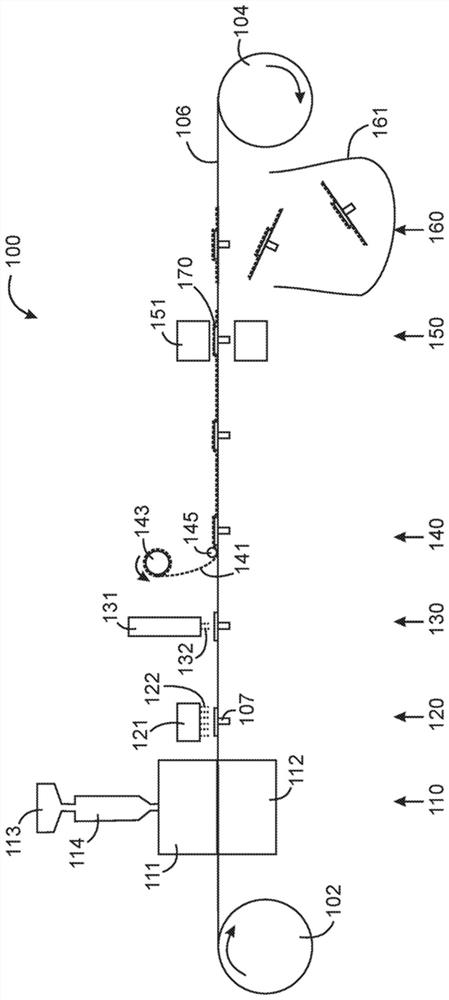

A sensor and electrode technology, applied in the production of biomedical electrodes, sensors for medical electrodes, and the production of sensors and medical electrodes, can solve problems such as limiting productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

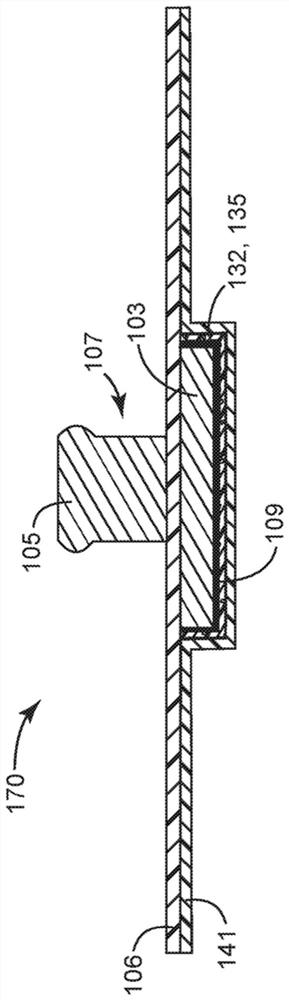

[0051] Example 1: Through Membrane Injection Molded Sensor

[0052] A small laboratory scale mold was fabricated with a design to produce an integral sensor shaped such that it would connect to current industry standard leads. Implement several variations on the currently used shapes to produce such as Figure 5 Sensor 400 is depicted. First, using an appropriately designed syringe (from Tulip TM Medical Products Company (Tulip TMMedical Products) form bulb 410 (ie, the larger diameter segment at the end of post 405). This enables the entire sensor 400 to be molded in one step, with the parting line perpendicular to the post axis. This variation facilitates molding through the membrane 401 as opposed to current injection molded sensors which have a parting line parallel to the post axis and do not mold the sensor through the membrane. An additional variation is to mold the membrane retention feature 407 directly into the sensor 400 . Membrane retention feature 407 perm...

Embodiment 2

[0055] Example 2: Performance Testing of Sensors Injected Through Membrane

[0056] Web injection molded sensors produced according to Example 1 were tested to assess the ability of the method to produce acceptable electrodes. 240 samples were produced with different backing materials and injection arrangements. The contact surface of each sensor was coated with silver / silver chloride screen-printable ink (DuPont grade 5880) and cured according to the manufacturer's instructions. Table 1 shows the data collected for all sensors molded through PET and polypropylene webs. Table 1 shows the resistance of the sensor. The value of the resistance was measured by clamping a standard lead connector to the end of the post and placing the lead to measure in wire contact on the contact face of the sensor. The columns labeled Area Resistance are the resistance values at points that touch the surface but are not in contact with the gate location. When the leads are placed in contac...

Embodiment 3

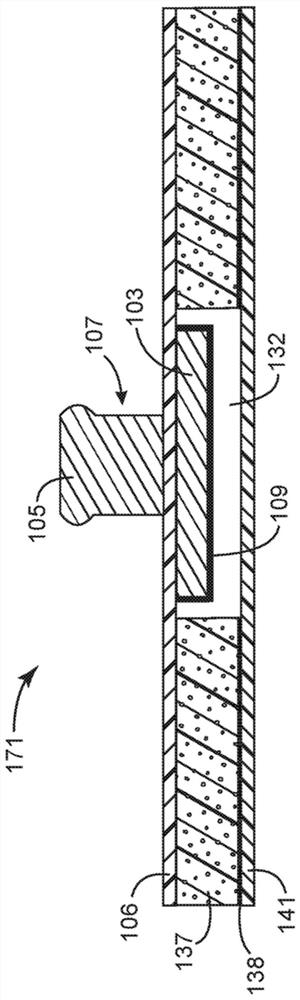

[0063] Embodiment 3: Preparation and performance test of ECG electrodes

[0064] Multiple sensors were molded through the polypropylene web for actual electrode testing. The sensor was coated with a silver / silver chloride screen printable ink (grade 5880) commercially available from DuPont. A polypropylene web with the sensor molded into it was bonded to a pre-punched foam backing centered on the gel well. A UV-curable electrolyte gel was added to the foam cavity on top of the web-injected sensor and cured. The electrodes were placed on paper liners and aged in a moisture-proof bag in an oven at 49°C for 2 days. The electrodes were taken out of the oven and out of the pouch, and placed in ambient laboratory conditions. Ten electrodes were tested every other week to determine electrode "out of bag" performance.

[0065] The primary measure of how well the sensor / web seal functions is the electrical performance of the electrodes when left "out of bag (OOB)" in an unsealed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com