Auxiliary device and method for accurately adjusting and fixing engineering laser resonant cavity lens

An auxiliary device and precision adjustment technology, which is applied in the direction of lasers, laser components, phonon exciters, etc., can solve the problems of time-consuming and labor-intensive adjustments, and difficulties in precise adjustment of laser resonator lenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

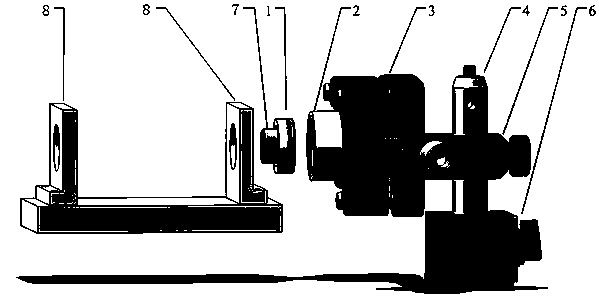

[0023] Specific Embodiment 1: This embodiment provides an auxiliary device for precise adjustment and fixing of engineering laser resonator mirrors. Since the laser resonator is usually composed of two mirrors, the above-mentioned precision adjustment and fixing assistance in actual operation The device needs two sets. Such as figure 1 As shown, each set of precision adjustment and fixing auxiliary devices is composed of a structural part 1 for installing a resonant cavity lens, a sleeve 2, an adjustment frame 3, an extension rod 4, a universal rod frame 5, and a magnetic base 6, wherein:

[0024] One end of the sleeve 2 is screwed to the structural member 1, and the other end is fixed on the adjustment frame 3;

[0025] The adjustment frame 3 is fixed on the universal rod frame 5;

[0026] The universal rod frame 5 is sleeved on the connecting rod 4;

[0027] The lower end of the connecting rod 4 is fixed on the magnetic base 6 .

[0028] In this embodiment, the structura...

specific Embodiment approach 2

[0034] Embodiment 2: This embodiment provides a method for using the precise adjustment and fixing device described in Embodiment 1 to realize the precise adjustment and fixing of engineering laser resonator mirrors. The method is implemented by the following steps:

[0035] Step 1, the resonant cavity lens 7 is cured and glued to the structural member 1 through ultraviolet glue;

[0036] Step 2. Assemble the magnetic base 6, the universal rod frame 5, the connecting rod 4 and the adjustment frame 3. The height and angle of the adjustment frame 3 can be adjusted;

[0037] Step 3: screw the structural part 1 and the sleeve 2 together through threads, and then fix the sleeve 2 on the adjustment frame 3, and the fixing between the two is completed by the top wire on the adjustment frame 3;

[0038] Step 4: Build the laser to be debugged used in the project, and fix the two resonant cavity frames 8 on which the resonant cavity lens 7 is installed to the laser base plate. The inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com