Ore grinding process modeling method based on neural network and evolutionary computation

A neural network and modeling method technology, applied in the field of iron ore grinding, can solve the problems of complex influence process, increase the difficulty of the beneficiation process, and increase the fluctuation of the particle size of the ground ore, so as to improve real-time performance and increase grinding production Efficiency, reducing the effect of adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

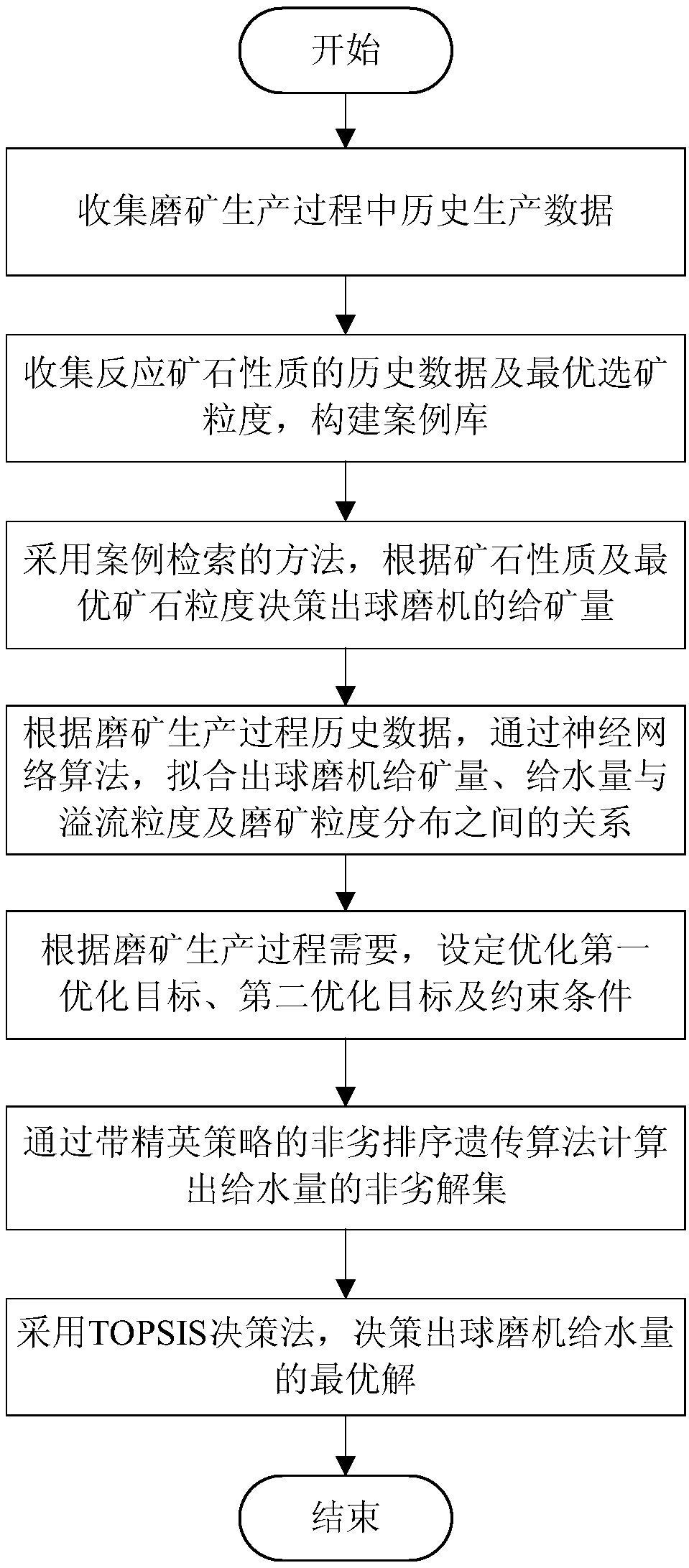

[0021] A modeling method of grinding process based on neural network and evolutionary computation, such as figure 1 shown, including the following steps:

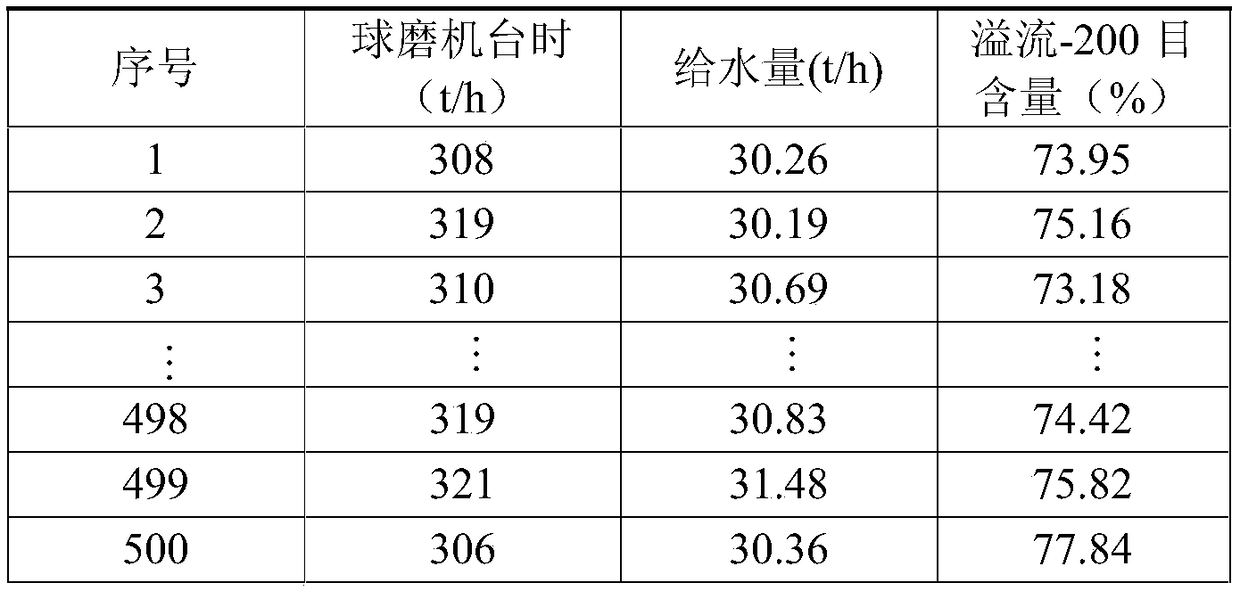

[0022] Step 1: Collect historical production data during the grinding process, including ball mill time, ball mill water supply and overflow particle size;

[0023] In this embodiment, some historical data of ball mill table hours, ball mill water supply and overflow particle size are shown in Table 1:

[0024] Table 1 Partial historical production data table of the grinding process

[0025]

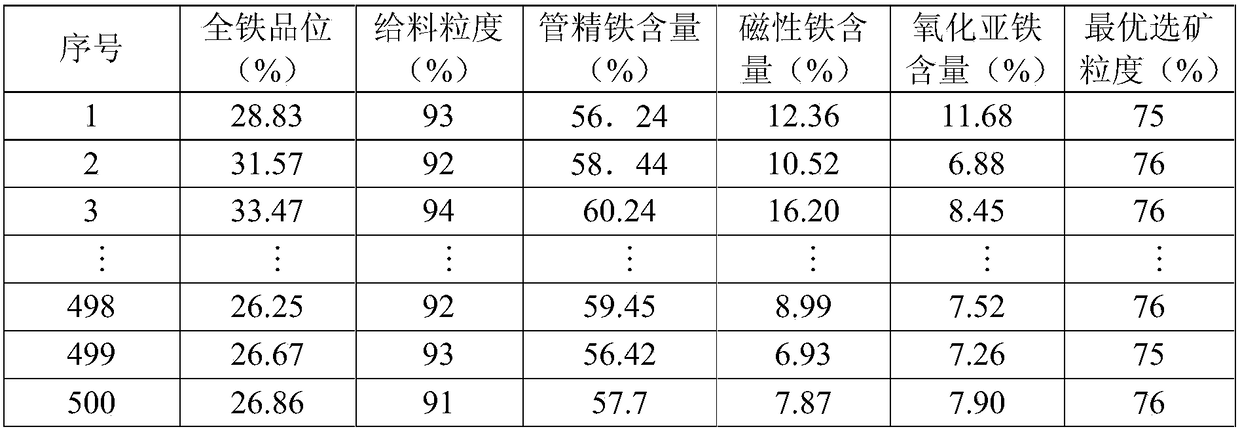

[0026] Step 2: collect the historical data of ore properties and the most preferred ore particle size; the historical data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com