All-weather smoke white plume eliminating system and method based on smoke waste heat and solar complementation

A flue gas waste heat and solar energy technology, which is applied in the field of all-weather flue gas white feather elimination system, can solve the problems of inability to coordinate the treatment of pollutants, poor whitening effect, and high energy consumption of whitening, so as to ensure long-term stable operation and improve economic efficiency. The effect of safety, reliability and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

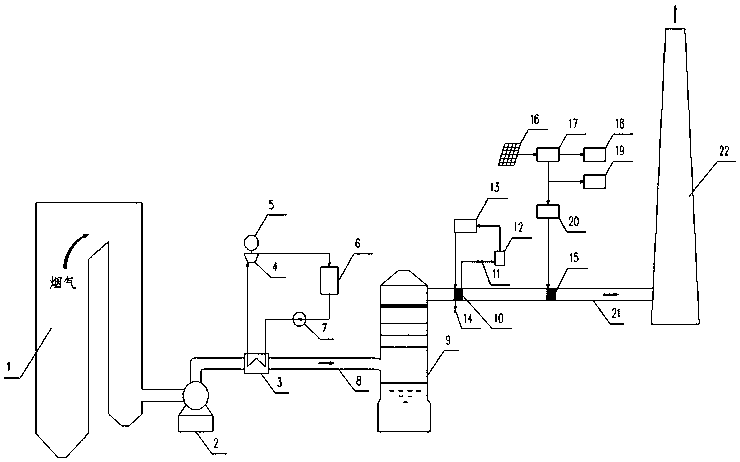

[0039] Embodiment 1: The all-weather flue gas white plume elimination system based on flue gas waste heat and solar energy complementarity includes a boiler 1, a desulfurization tower 9, an organic Rankine cycle system, a flue gas cooling system and a flue gas reheating system; the boiler 1 passes through The desulfurization tower inlet flue 8 is connected with the inlet of the desulfurization tower 9, the desulfurization tower inlet flue 8 is connected with an organic Rankine cycle system, and the flue gas generated by the combustion of the boiler 1 passes through the organic Rankine cycle system and then passes through the organic rankine cycle system. The desulfurization tower inlet flue 8 is sent into the desulfurization tower 9; the outlet of the desulfurization tower 9 is connected with the chimney 22 through the desulfurization tower outlet flue 21; the flue gas cooling system and the Flue gas reheating system; the flue gas generated by the combustion of the boiler 1 pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com