A kind of metal mold gravity casting aluminum alloy material and preparation method thereof

An aluminum alloy material and gravity casting technology, applied in the field of metal materials, can solve the problems of large fluctuation of alloy tensile strength, the reliability of strength needs to be improved, etc., and achieve improved casting performance, simple preparation method, and good process stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

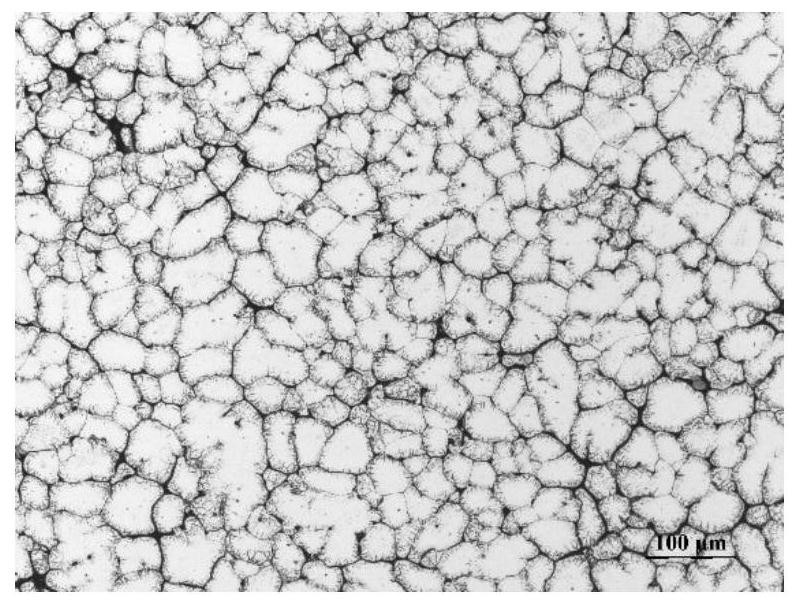

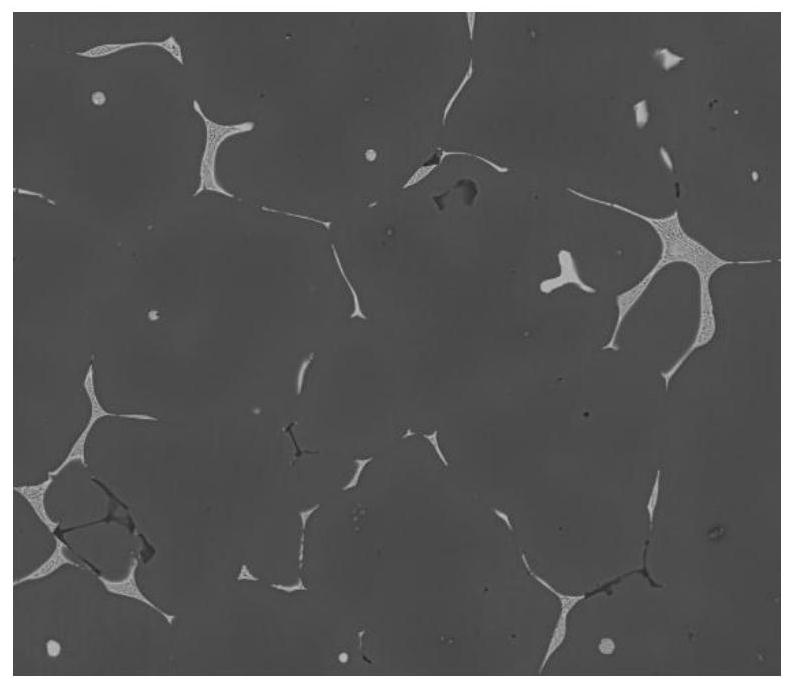

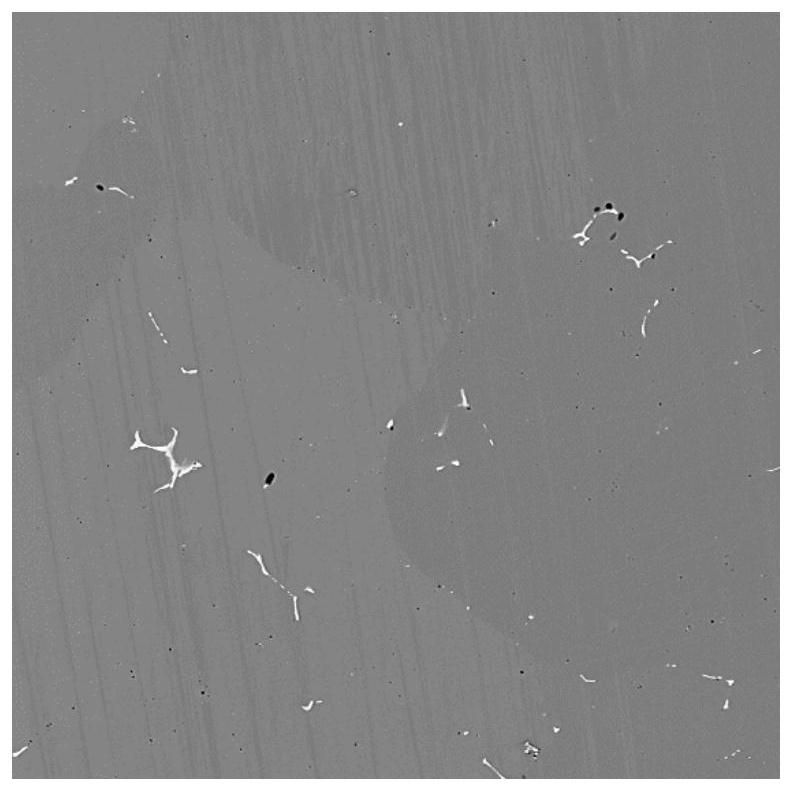

Image

Examples

Embodiment 1

[0044]The metal type gravity casting aluminum alloy material provided in this embodiment is composed of the following elements in mass percentage: Mg: 2.0%, Zn: 3.0%, Cu: 0.5%, Y: 0.01%, Ti: 0.01%, B: 0.002% , Sr: 0.1%, Zr: 0.1%, and unavoidable impurities Fe≤0.15%, Si≤0.15%, Al balance.

[0045] The metal mold gravity casting method of the aluminum alloy provided in this embodiment, the steps are as follows:

[0046] a. Melting the alloy to obtain an aluminum alloy melt.

[0047] The smelting steps are: (1) Bake the material, preheat the raw material at 250°C for 2 hours; (2) Smelt, set the melting temperature of the melting furnace to 710°C, and when the furnace temperature rises to 300°C, add industrial pure aluminum, aluminum and copper Alloy, until the melt is clear, and stir evenly; when the melt temperature drops to 690°C, add industrial pure zinc and industrial pure magnesium, melt, and stir evenly, until melt clear; heat the melt to 740°C, add aluminum-yttrium Inter...

Embodiment 2

[0053] The metal type gravity casting aluminum alloy material provided in this embodiment is composed of the following elements in mass percentage: Mg: 2.0%, Zn: 3.0%, Cu: 0.5%, Y: 0.01%, Ti: 0.01%, Sr: 0.1% , Zr: 0.1%, and unavoidable impurities Fe≤0.15%, Si≤0.15%, Al balance.

[0054] The metal mold gravity casting method of the aluminum alloy provided in this embodiment, the steps are as follows:

[0055] a. Melting the alloy to obtain an aluminum alloy melt. Melting steps: (1) Bake the material, preheat the raw material at 250°C for 2 hours; (2) Melt, set the melting temperature of the melting furnace to 710°C, when the furnace temperature rises to 300°C, add industrial pure aluminum, aluminum-copper master alloy , until the melt is clear, and stir evenly; when the melt temperature drops to 690°C, add industrial pure zinc and industrial pure magnesium, melt, and stir evenly, until the melt is clear; heat the melt to 740°C, and add aluminum-yttrium intermediate Stir the a...

Embodiment 3

[0060] The metal type gravity casting aluminum alloy material provided in this embodiment is composed of the following elements in terms of mass percentage: Mg: 2.0%, Zn: 3.0%, Cu: 0.5%, cerium-rich mixed rare earth: 1.5%, Ti: 0.01%, B: 0.002%, Sr: 0.1%, Zr: 0.15%, and unavoidable impurities Fe≤0.15%, Si≤0.15%, the balance of Al.

[0061] This embodiment provides a metal mold gravity casting method for the aluminum alloy, the steps are as follows:

[0062] a. Melting the alloy to obtain an aluminum alloy melt. Melting steps: (1) Bake the material, preheat the raw material at 250°C for 2 hours; (2) Melt, set the melting temperature of the melting furnace to 710°C, when the furnace temperature rises to 300°C, add industrial pure aluminum, aluminum-copper master alloy , until the melt is clear, and stir evenly; when the melt temperature drops to 690°C, add industrial pure zinc and industrial pure magnesium, melt, and stir evenly, until the melt is clear; heat the melt to 740°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com