Method of preparing nano black phosphorus by black phosphorus stripping through liquid nitrogen

A technology of black phosphorus and liquid nitrogen, applied in the field of nanomaterials, can solve the problems of expensive equipment, destruction of black phosphorus, and harsh preparation conditions, and achieve the effect of low cost and avoiding oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

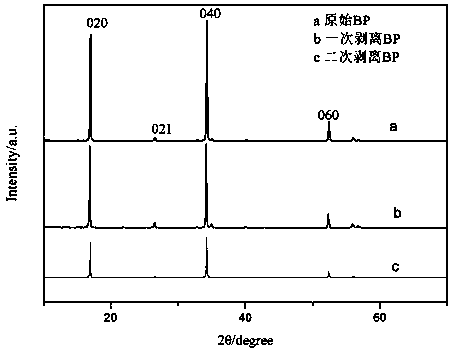

Image

Examples

Embodiment 1

[0021] Embodiment 1: a kind of method that liquid nitrogen strips black phosphorus and prepares nanometer black phosphorus, concrete steps are as follows:

[0022] (1) In an inert gas (nitrogen) atmosphere, add 500mg of black phosphorus blocks to 1000mL of liquid nitrogen, where the solid-to-liquid ratio mg:mL of black phosphorus to liquid nitrogen is 0.5:1; at a temperature of -196°C Next, use a constant temperature oscillator to carry out constant temperature oscillation treatment for 1 hour to realize liquid nitrogen intercalation of black phosphorus to obtain black phosphorus / liquid nitrogen dispersion liquid; volatilize liquid nitrogen in black phosphorus / liquid nitrogen dispersion liquid to strip black phosphorus to obtain black phosphorus exfoliated material A ; Wherein liquid nitrogen volatilization adopts the heating method;

[0023] (2) Return the black phosphorus stripping material A to step (1) to replace the black phosphorus for liquid nitrogen stripping, and perf...

Embodiment 2

[0027] Embodiment 2: a kind of method that liquid nitrogen strips black phosphorus and prepares nanometer black phosphorus, concrete steps are as follows:

[0028] (1) In an inert gas (argon) atmosphere, add 10mg of black phosphorus blocks into 1000mL of liquid nitrogen, where the solid-to-liquid ratio mg:mL of black phosphorus to liquid nitrogen is 0.1:1; at a temperature of -150°C Under certain conditions, use a constant temperature oscillator to carry out constant temperature oscillation treatment for 2 hours to realize liquid nitrogen intercalation black phosphorus to obtain black phosphorus / liquid nitrogen dispersion; volatilize the liquid nitrogen in the black phosphorus / liquid nitrogen dispersion to strip black phosphorus to obtain black phosphorus exfoliation A; The liquid nitrogen volatilization adopts the method of decompression;

[0029] (2) Return the black phosphorus stripping material A to step (1) to replace the black phosphorus for liquid nitrogen stripping, an...

Embodiment 3

[0031] Embodiment 3: a kind of method that liquid nitrogen strips black phosphorus and prepares nanometer black phosphorus, concrete steps are as follows:

[0032] (1) In an inert gas (mixed gas of nitrogen and argon) atmosphere, add 1000mg of black phosphorus blocks into 200mL of liquid nitrogen, where the solid-to-liquid ratio mg:mL of black phosphorus to liquid nitrogen is 5:1; at temperature Under the condition of -100°C, use a constant temperature oscillator to carry out constant temperature shaking treatment for 5 hours to realize liquid nitrogen intercalation black phosphorus to obtain black phosphorus / liquid nitrogen dispersion liquid; volatilize liquid nitrogen in black phosphorus / liquid nitrogen dispersion liquid to strip black phosphorus. Black phosphorus stripping thing A; Wherein liquid nitrogen volatilization adopts the mode of decompression;

[0033] (2) Return the black phosphorus stripping material A to step (1) to replace the black phosphorus for liquid nitro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com