Pulse cleaning tool

A technology of pulse cleaning and tools, which is applied in the direction of cleaning methods and utensils, cleaning hollow objects, chemical instruments and methods, etc., can solve the problems of unsatisfactory effect and inability to clean in all directions, and achieve effective cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation of the present invention will now be described with reference to the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

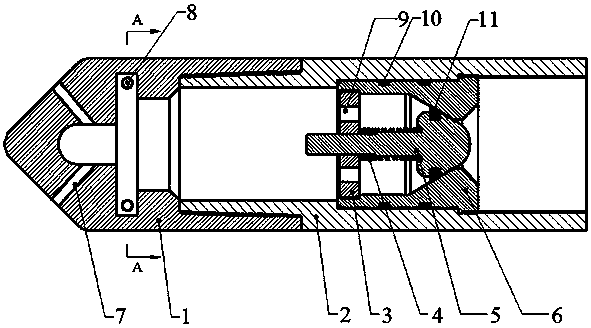

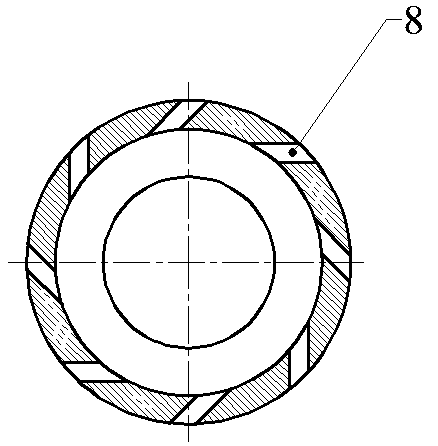

[0018] Such as figure 1 and figure 2 As shown, the present invention provides a pulse cleaning tool, which is composed of a jet nozzle 1, a housing 2, an overflow plate 3, a spring 4, a valve stem 5, a valve seat 6, an O-ring 10 and a sealing ring 11; The front end of the jet nozzle 1 is processed with an oblique jet hole 7, and its circumferential direction is provided with a tangential jet hole 8; The two ends of the housing 2 are open; the valve seat 6 is in a figure-eight shape, and the large end opening of the valve seat 6 is installed with the flow plate 3, and the lower end of the valve stem 5 is inserted into the center hole of the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com