Automatic separation type stripping machine of wire core for cable

An automatic separation, wire and cable technology, applied in the field of wire and cable, can solve the problem of wasting time and manpower, and achieve good stripping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

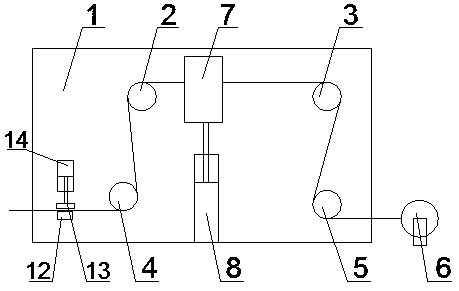

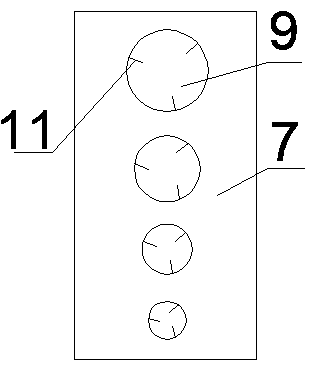

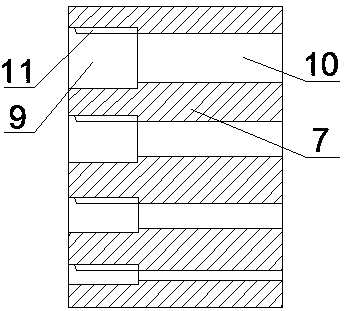

[0018] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0019] like Figure 1~3 As shown, a wire core automatic separation type peeling machine for wires and cables includes a side plate 1, a peeling mechanism arranged on the side plate 1, a first guide wheel 2, a second guide wheel 3, a third guide wheel 4, a Four guide wheels 5 and damping mechanism, and the take-up mechanism 6 that is arranged on side plate 1 side, described stripping mechanism comprises blade holder 7 and linear drive device A8, and blade holder 7 is cuboid structure, blade holder 7 Slidingly connected with the side plate 1, the blade fixing seat 7 is connected with the output shaft of the linear drive device A8, the blade fixing seat 7 can make a straight line movement in the vertical direction, and the left end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com