DC+ and DC- parallel-cooling soft wire of liquid-cooling cable for large-power charging pile

A high-power charging, liquid-cooling technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of difficult connection of the charging gun, affecting the flexibility, difficulty, etc., and achieve excellent chemical stability, high lubrication and no resistance. Good viscosity and electrical insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In conjunction with accompanying drawing, the present invention is described in further detail as follows by the mode of embodiment:

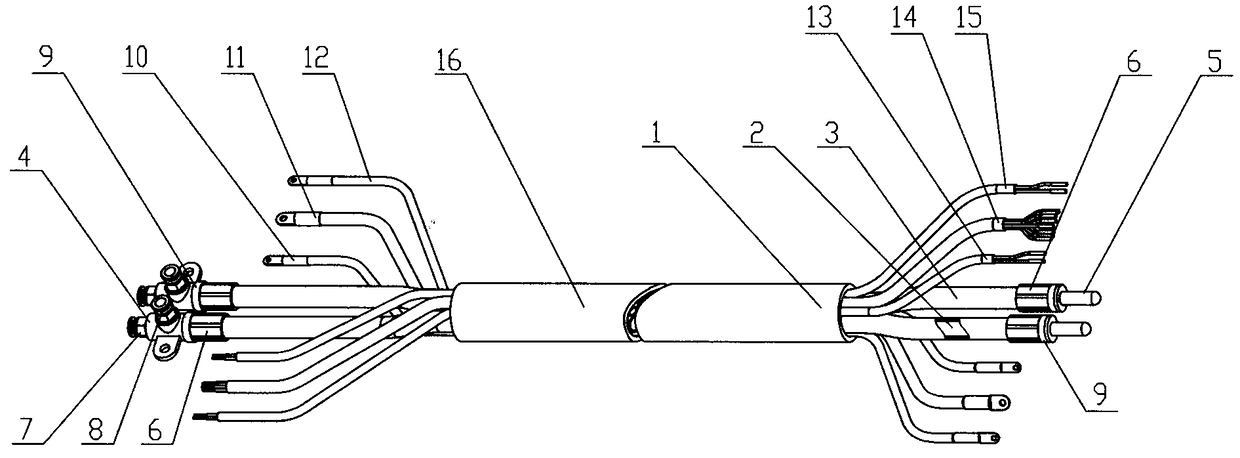

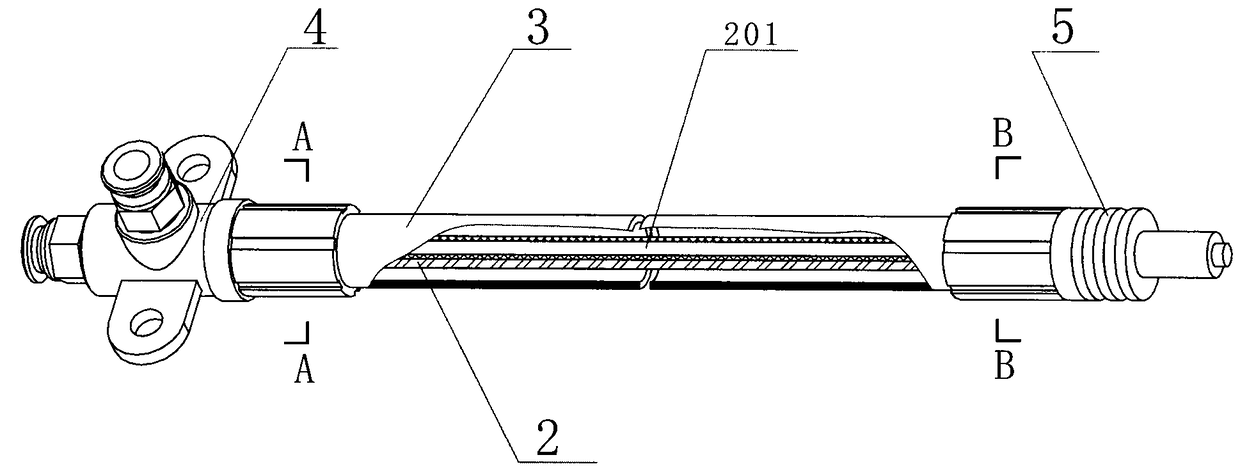

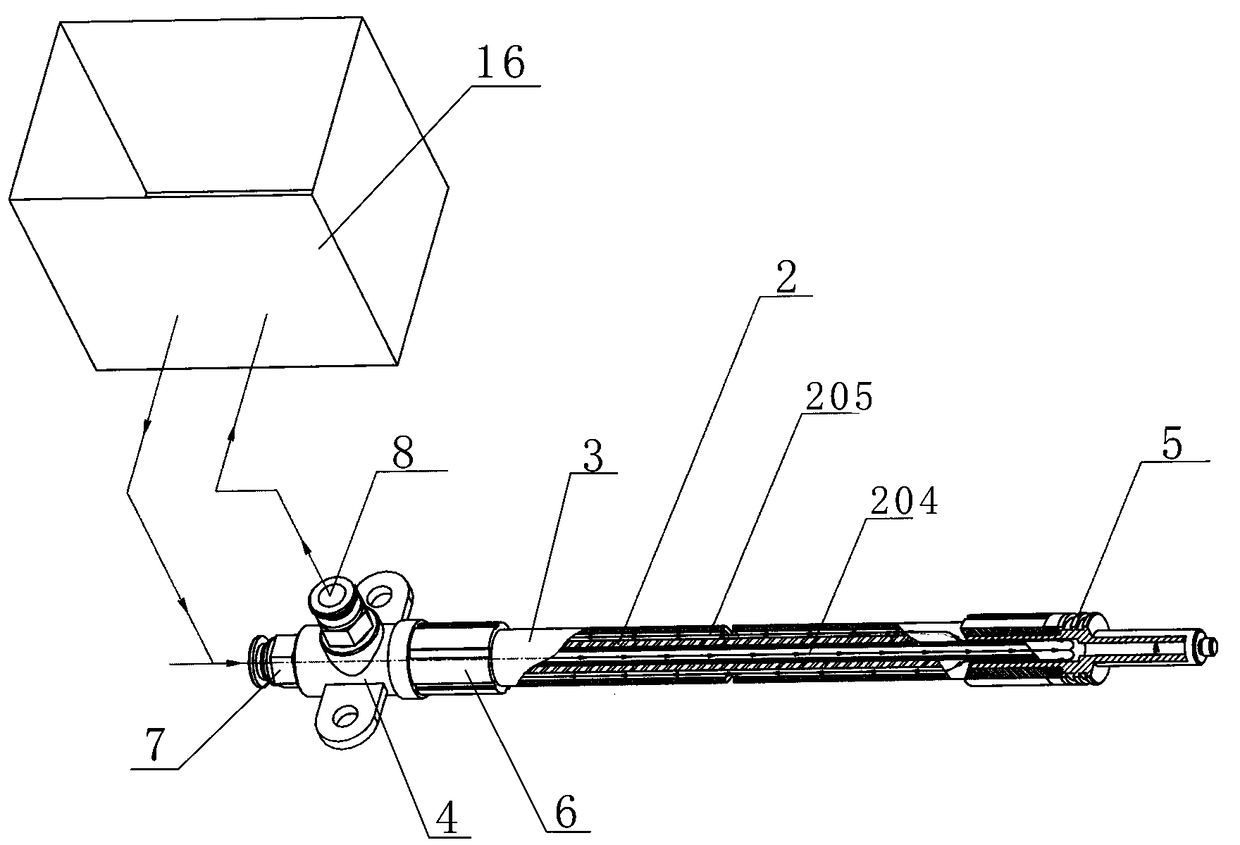

[0022] Such as figure 1 As shown: a liquid-cooled cable DC+ and DC- parallel cooling soft wire for high-power charging piles described in this embodiment includes a cooling liquid inner tube 201, a soft conductor 202 and a protective copper mesh 203. The cooling liquid inner tube 201 It is a polytetrafluoroethylene tube that runs through the center of the soft conductor, the inner and outer diameter of the tube is 190 meters in length; the soft conductor 202 is a multi-strand wire core with a cross-section of 35-60 square millimeters, each The stranded wire core is made of multiple small-diameter tinned copper single wires twisted into small strands, and then multiple small strands are twisted into a soft conductor; the soft conductor 202 is wrapped with a protective copper mesh 203, the protection The copper mesh is a woven mesh of tin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com