A jet device and design method for effectively suppressing cavitation on blade surface

A technology of jet device and surface cavitation, applied in components, design optimization/simulation, computer-aided design, etc. of pumping device for elastic fluid, to achieve the effect of suppressing shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

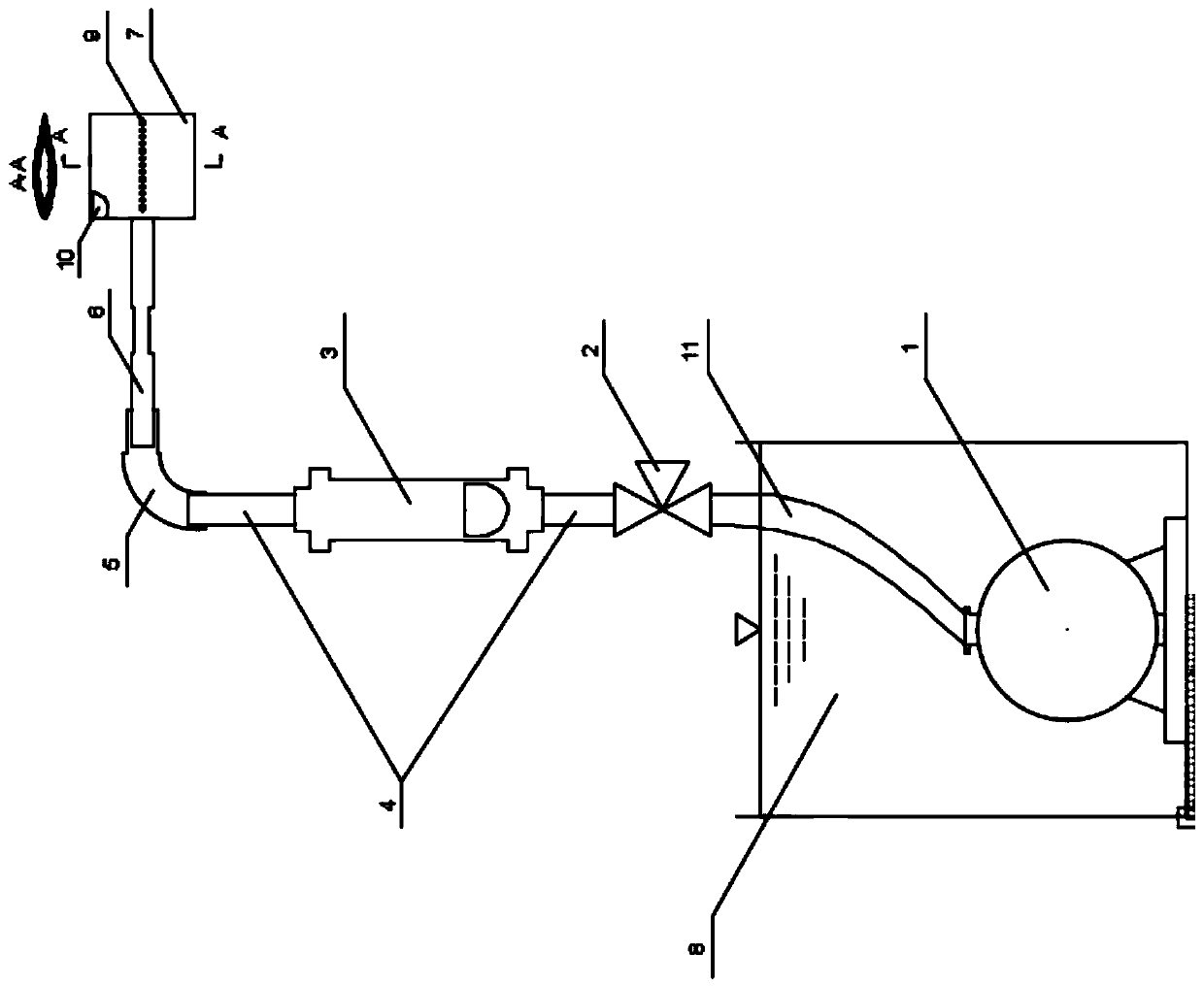

[0019] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

[0020] Such as figure 1 As shown, the present invention is a jet device and a design method for effectively suppressing cavitation on the blade surface, mainly consisting of a pump 1, a three-way valve 2, a flow meter 3, a PVC pipe 4, an elbow 5, a blade cavity connecting pipe 6, Composed of blades 7, water tanks 8, jet holes 9, blade cavities 10, and metal pipes 11;

[0021] (1) According to the needs of the design, the flow rate of the selected pump is 2800L / h, the diameter of each interface in the whole pipeline is 20cm, and the diameter of the PVC pipe and the metal pipe is also 20cm; the structure of the original hydraulic mechanical blade 7 is NACA66 (MOD) airfoil, The vane angle of inflow is 8°, the incoming flow velocity is 11.83m / s, the incoming flow pressure is 101.325kPa, the temperature is 20°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com