Waterproofing process for underground excavating side wall of station in water-rich stratum

A technology for water-rich strata and side walls, applied in underground chambers, wellbore linings, tunnel linings, etc., can solve problems affecting construction and pouring quality, achieve significant economic and social benefits, wide application prospects, and simple principles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further explained below in conjunction with the drawings and embodiments:

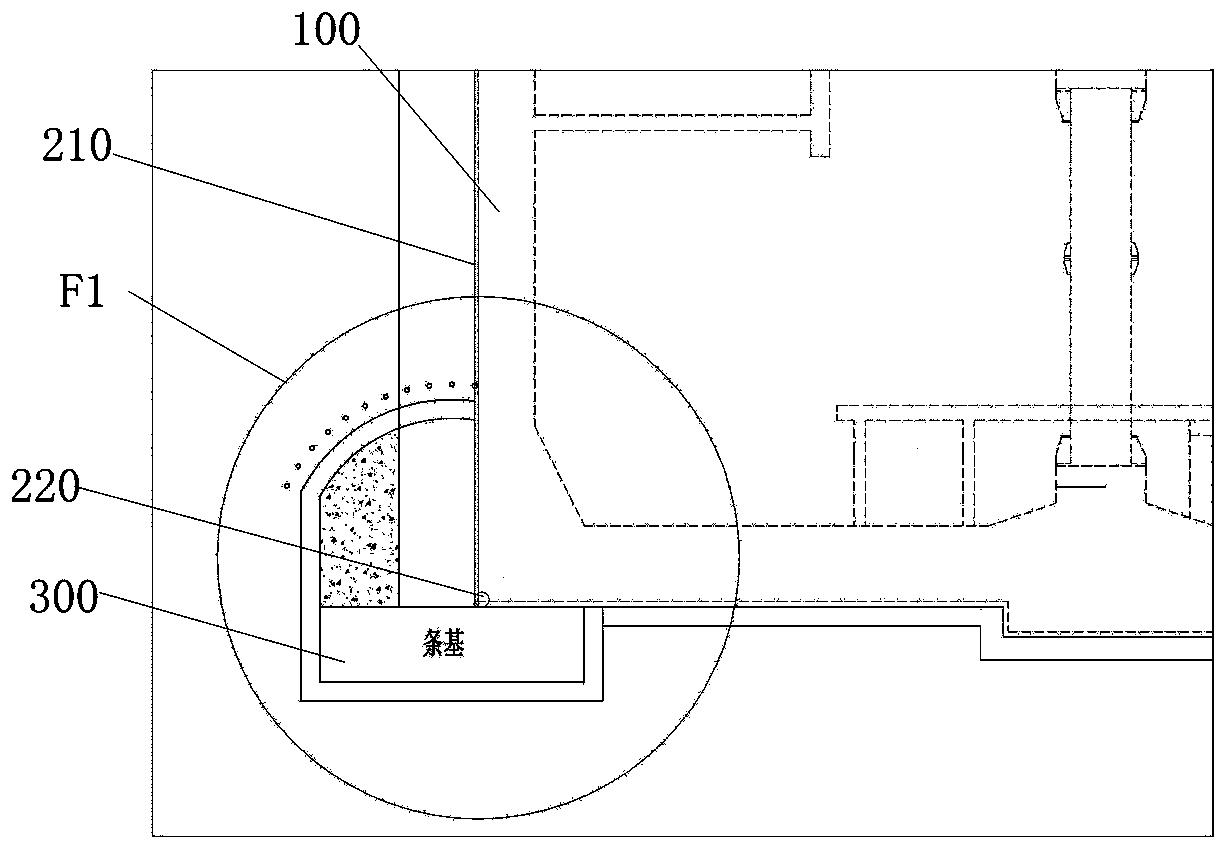

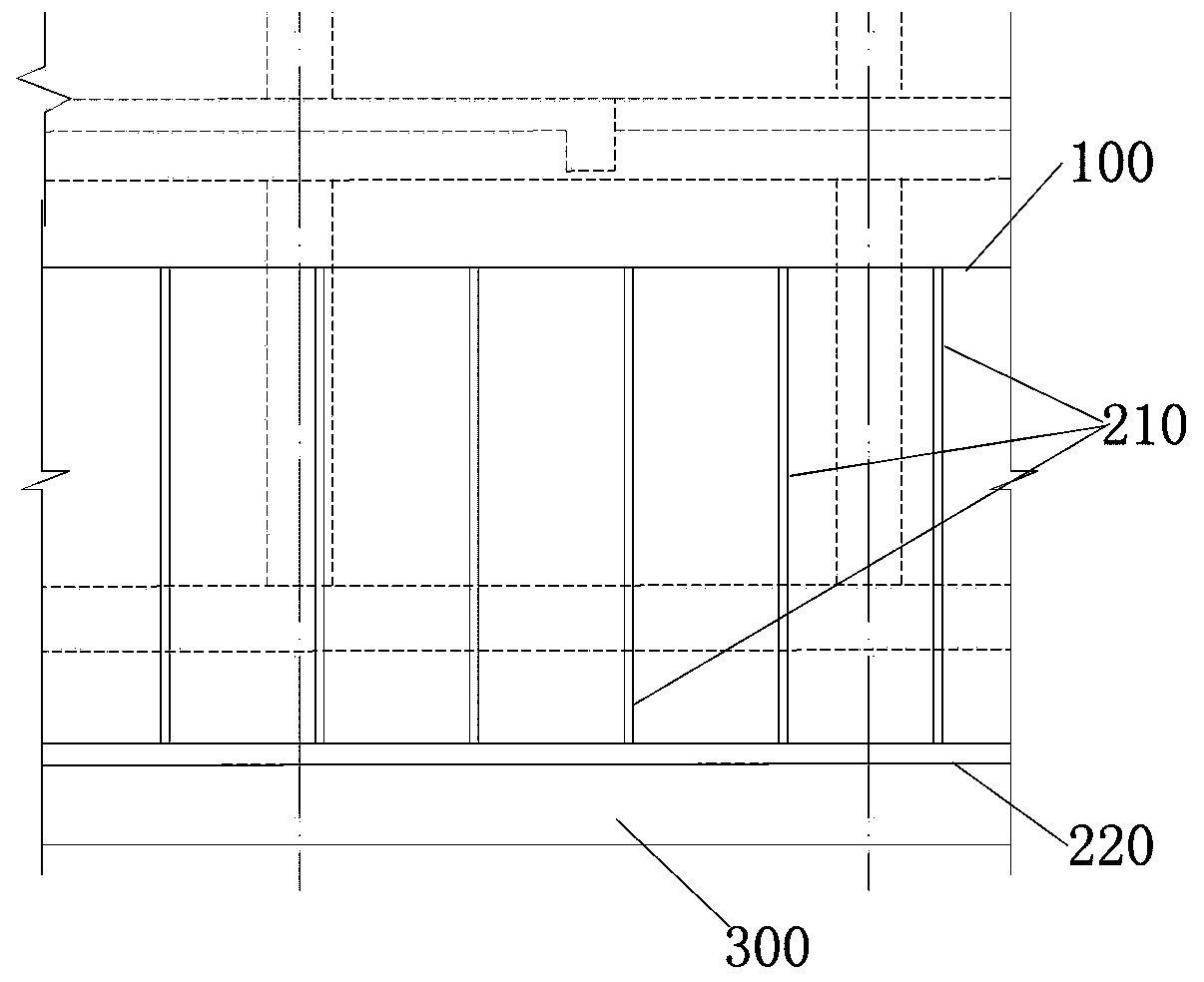

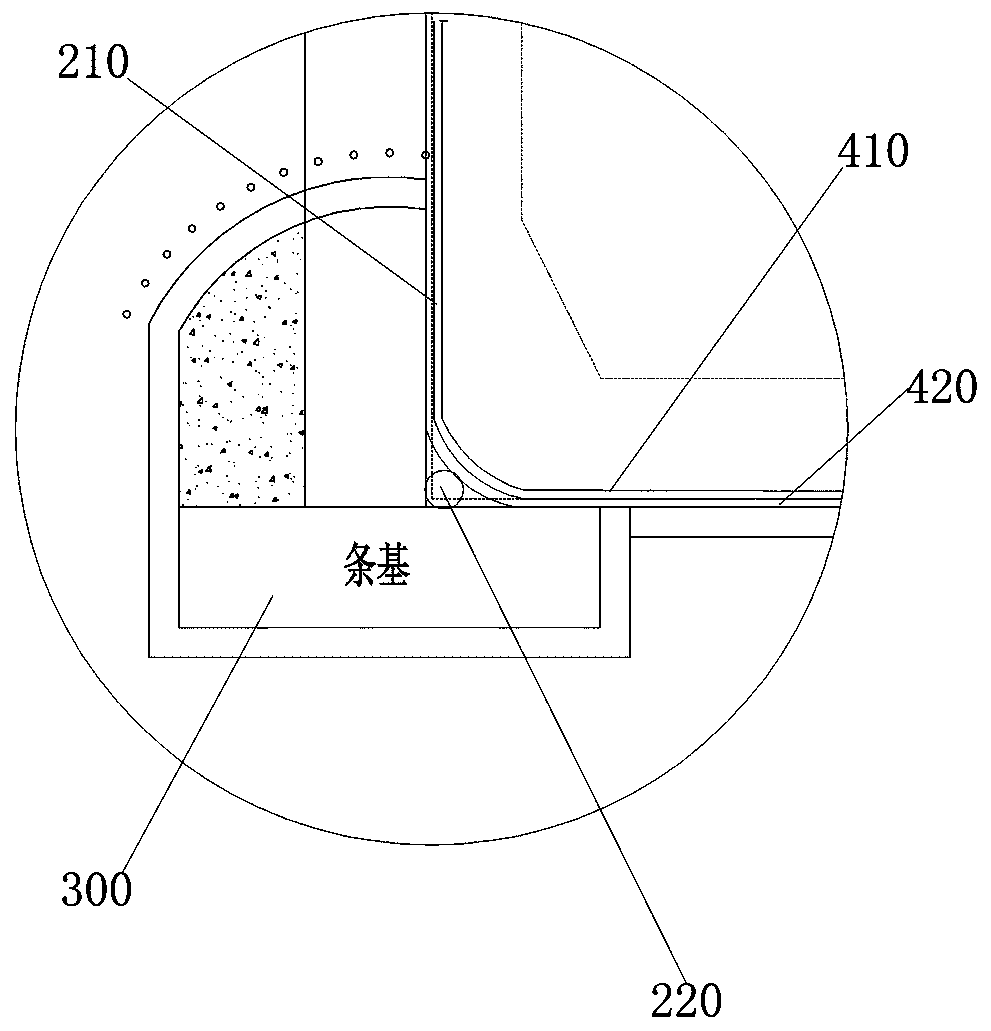

[0023] See Figure 1-Figure 5 , A waterproof technology for subsurface excavation of station side walls in water-rich stratum, including the following steps:

[0024] S1. Treat the surface flatness and protrusions of the side wall to make it level, and then lay a vertical (side wall height direction) vertical blind pipe 210; the vertical blind pipe 210 is close to the surface of the side wall, and The bottom of the vertical blind pipe 210 and the vertical blind pipe 220 that cross it communicates and diverts;

[0025] S2. Lay a plastic sheet 430 on the side wall. The plastic sheet 430 clamps the vertical blind pipe 210 and the vertical blind pipe 220 between the surface of the side wall and the plastic sheet 430; the plastic sheet 430 can be used as the surface of the side wall and the waterproof layer An additional layer in between plays the role of water isolation and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com