Grid steel frame, grid steel frame trial assembling device and grid steel frame manufacturing method

A technology of grid steel frame and trial assembly, which is applied in auxiliary devices, shaft equipment, earthwork drilling and mining, etc., can solve the problem of insufficient support strength of grid steel frame, low qualification rate of grid steel frame, and inconvenience of grid steel frame Installation and construction, etc., to achieve the effect of flexible construction method, stable structure and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Please also refer to Figure 1 to Figure 8 .

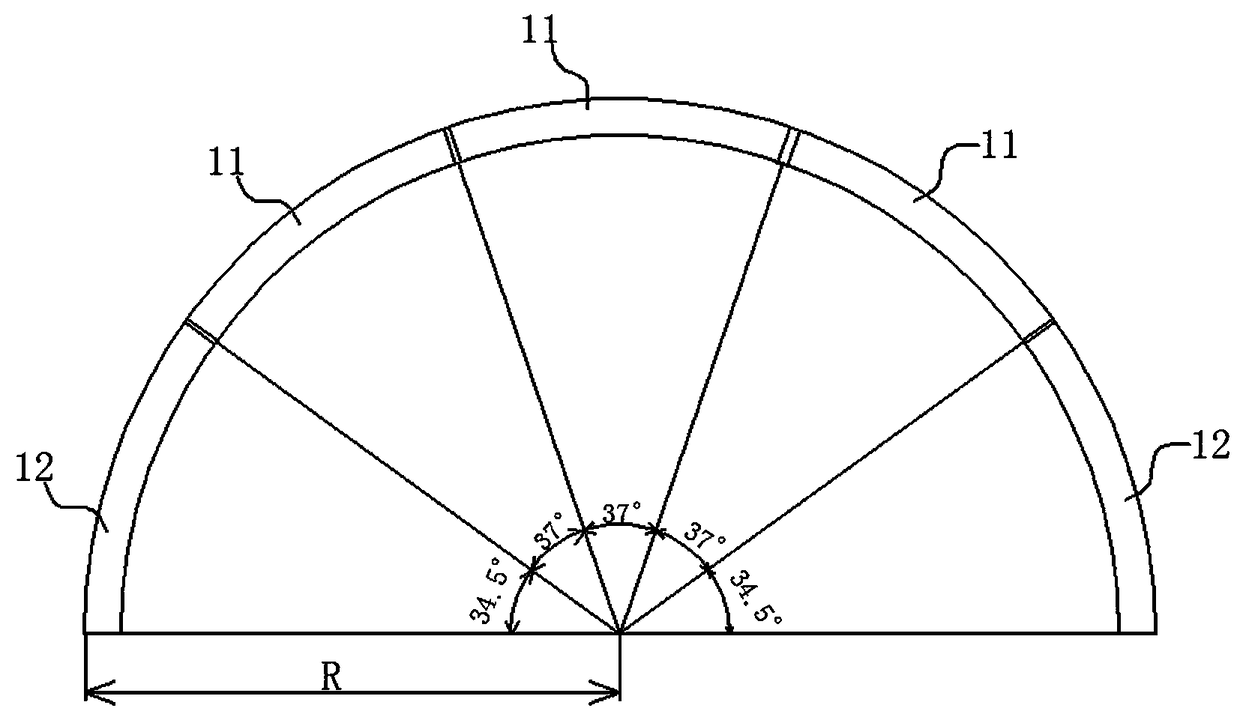

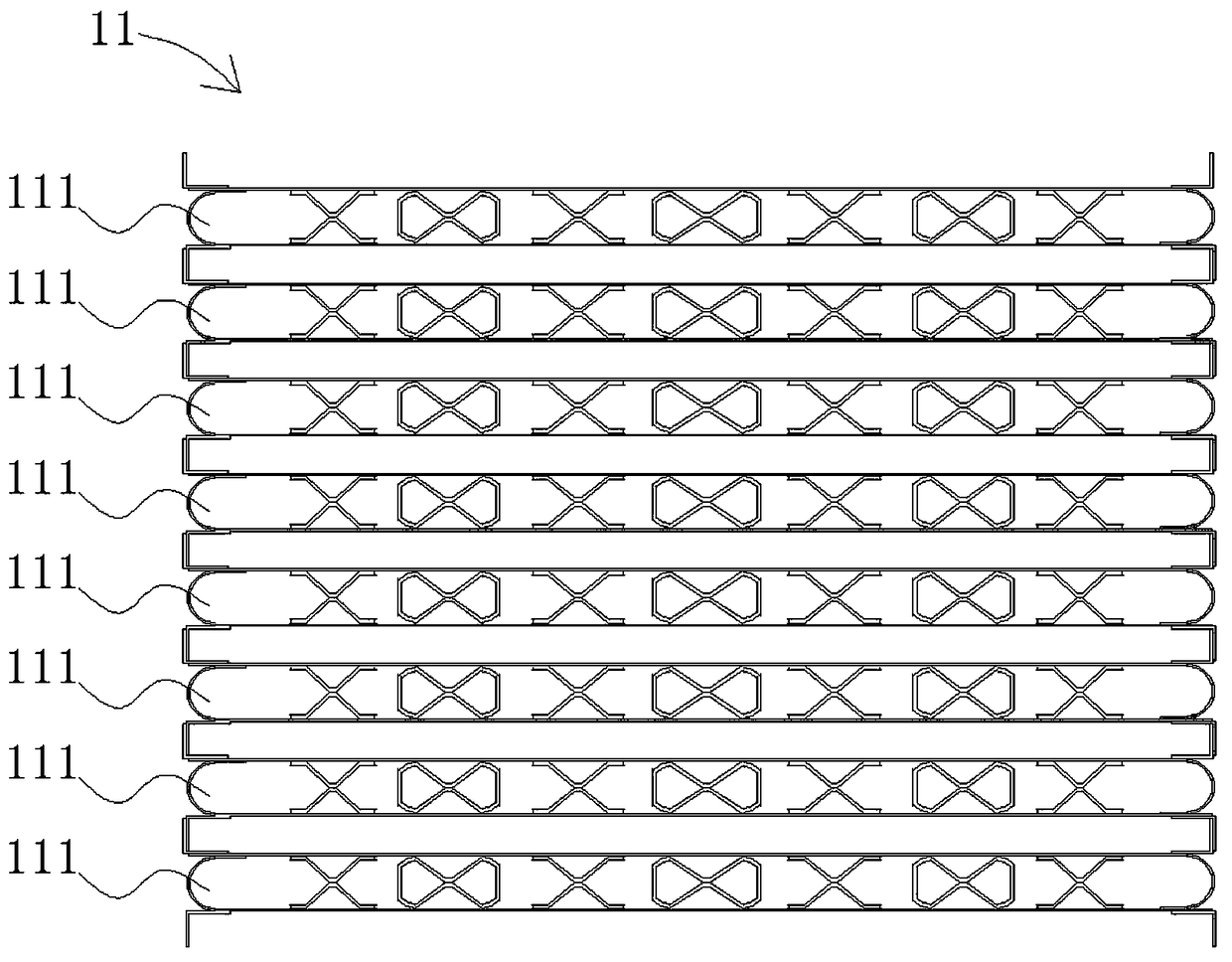

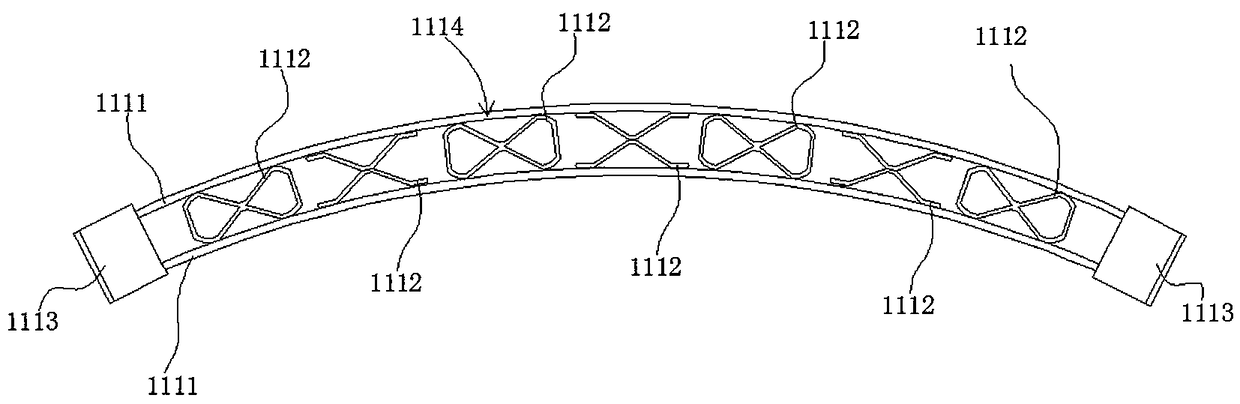

[0056] The grid steel frame provided by the embodiment of the present invention includes a plurality of grid modules, and each grid module is arc-shaped. 180° camber type. Such as figure 1 As shown, the grid modules in the grid steel frame in this embodiment include three first grid modules 11 located in the middle of the grid steel frame and connected in sequence, and two second grid modules 11 respectively located on both sides of the grid steel frame. Grid modules 12, the specifications of the first grid module 11 are the same, and its radian is 37°; °The two ends of the arc-shaped arched grid steel frame can be supported on the ground of the tunnel, which is beneficial to enhance the bearing capacity of the grid steel frame. The radius R of the grid steel frame is 7 meters. During actual processing and production, the radius R of the grid steel frame is determined according to the radius measurement of the surroundi...

Embodiment 2

[0063] Please also refer to Figure 9 to Figure 11 .

[0064] Such as Figure 9 As shown, the grid steel frame trial assembly device provided by the embodiment of the present invention includes 15 pedestals 21, and the 15 pedestals 21 are arranged in an arc corresponding to the grid steel frame in Example 1. Each of the pedestals in Example 1 One grid module corresponds to three pedestals 21 as supports, and by placing each support unit corresponding to the grid steel frame on the pedestal 21, the grid steel frame trial assembly device can be used for trial assembly of the grid steel frame in Example 1 The bracket units corresponding to each grid module can be used to check whether the bracket units corresponding to different grid units of the produced grid steel frame can be assembled into a semicircle. If they can be assembled into a semicircle, it indicates that each bracket If the unit is qualified, if it cannot be assembled into a semicircle, the corresponding bracket u...

Embodiment 3

[0069] Please also refer to Figure 12 to Figure 15 .

[0070] Such as Figure 12 As shown, the grid steel frame manufacturing method provided by the embodiment of the present invention specifically includes the following steps:

[0071] S10: Processing raw materials, making main bars, 8-shaped bars and connecting plates;

[0072] S20: making a bracket unit corresponding to each grid module;

[0073] S30: Trial assembling the bracket units corresponding to each grid module.

[0074] Specifically, such as Figure 13As shown, the grid steel frame manufacturing method first inspects the raw materials, these raw materials include the steel bars used to make the main bars, the steel bars used to make the 8-shaped bars and the angle steel used to make the connecting plates, and the raw materials that pass the inspection can be The unqualified raw materials will enter the unqualified treatment process, and the unqualified treatment includes scrapping, or used in other occasions ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com