Self-supporting butterfly-shaped leading-in optical cable convenient for construction

A self-supporting technology of introducing optical cables, applied in the directions of light guides, optics, optical components, etc., can solve the problems of inconvenient construction, reduced use occasions, construction efficiency, slow construction speed, etc., and achieves high qualification rate and flexible construction methods. Various and fast construction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

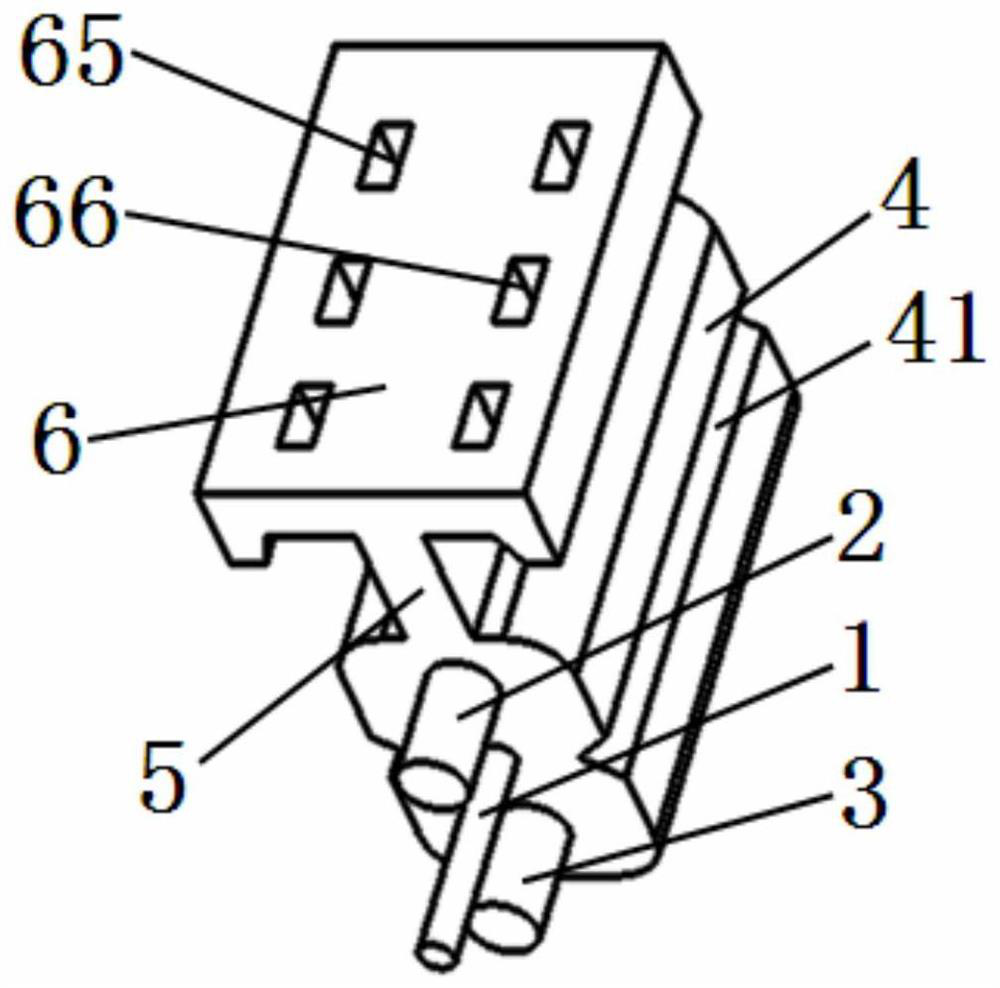

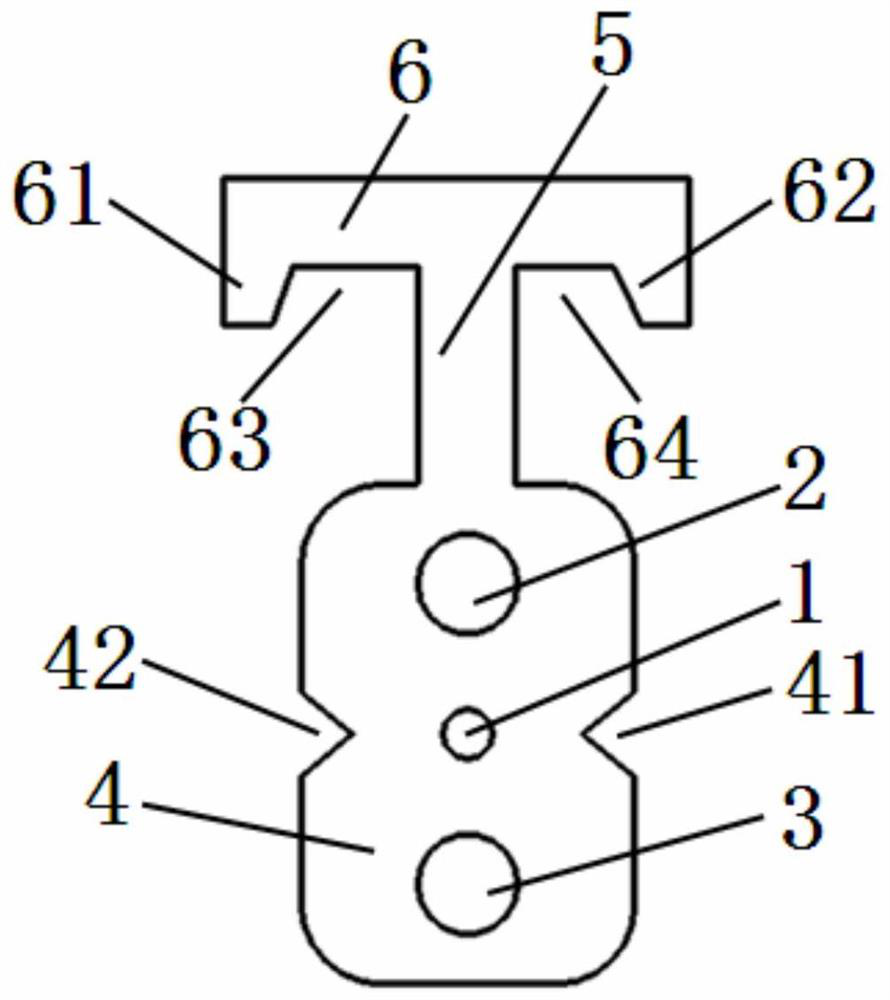

[0025] please see figure 1 and figure 2 , a self-supporting butterfly-shaped lead-in optical cable that is convenient for construction, has an integrated butterfly-shaped lead-in unit, a connecting rib 5, and an anchor body 6, the upper end of the butterfly-shaped lead-in unit is connected with the lower end of the connecting rib 5, and the upper end of the connecting rib 5 Linked to the lower surface of the hanging body 6, the butterfly-shaped introduction unit consists of an optical fiber 1, a first reinforcement 2 positioned above the optical fiber, a second reinforcement 3 positioned below the optical fiber, and the optical fiber and the first and second The sheath 4 covered by the reinforcing member is composed of a first tear opening 41 on the sheath edge on the right side of the optical fiber, and a second tear opening 42 on the left sheath edge of the optical fiber; it is characterized in that The upper surface of the anchoring body is a plane, the left-right symmetr...

Embodiment 2

[0028] please see image 3 , and refer to figure 1 and figure 2 , a self-supporting butterfly-shaped lead-in optical cable that is convenient for construction, has an integrated butterfly-shaped lead-in unit, a connecting rib 5, and an anchor body 6, the upper end of the butterfly-shaped lead-in unit is connected with the lower end of the connecting rib 5, and the upper end of the connecting rib 5 Linked to the lower surface of the hanging body 6, the butterfly-shaped introduction unit consists of an optical fiber 1, a first reinforcement 2 positioned above the optical fiber, a second reinforcement 3 positioned below the optical fiber, and the optical fiber and the first and second The sheath 4 covered by the reinforcing member is composed of a first tear opening 41 on the sheath edge on the right side of the optical fiber, and a second tear opening 42 on the left sheath edge of the optical fiber; it is characterized in that The upper surface of the anchoring body is a plan...

Embodiment 3

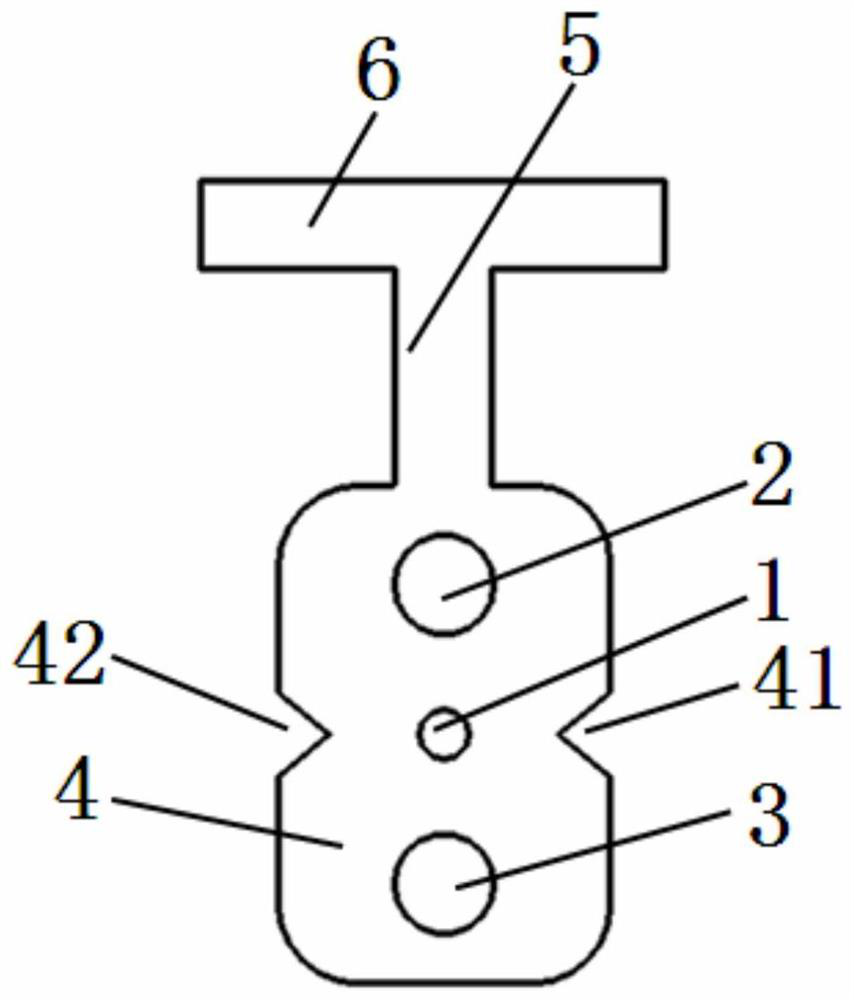

[0031] please see Figure 4 and Figure 5, a self-supporting butterfly-shaped lead-in optical cable that is convenient for construction, has an integrated butterfly-shaped lead-in unit, connecting rib 5, and anchoring body 6, the right end of the butterfly-shaped lead-in unit is connected with the left end of the connecting rib 5, and the right end of the connecting rib 5 Linked to the left surface of the hanging body 6, the butterfly-shaped introduction unit consists of an optical fiber 1, a first reinforcement 2 above the optical fiber, a second reinforcement 3 below the optical fiber, and the optical fiber and the first and second The sheath 4 covered by the reinforcing member is composed of a first tear opening 41 on the left side of the sheath edge of the optical fiber; it is characterized in that the right surface of the anchoring body is a plane, and the upper and lower symmetrical planes of the connecting ribs are aligned with the upper and lower symmetric planes of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com