Prefabricated pre-stressed beam member, fabricated combined frame structure and installation method of fabricated combined frame structure

A technology for prestressed beams and frame structures, which is applied to structural elements, building components, and elongated structural components for load-bearing, etc. On-site installation of beam-column joints requires a lot of work and high requirements for positioning of protruding steel bars, so as to achieve the effect of high binding installation efficiency, saving measures cost, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

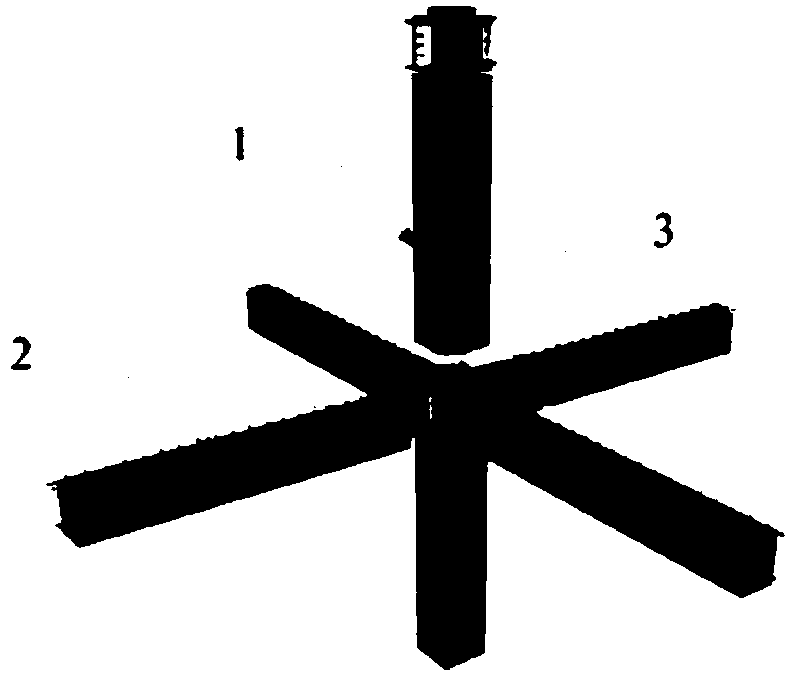

[0034] Such as figure 1 , the prefabricated composite frame structure of the present invention includes a prefabricated column member 1 having a beam-column joint area 3 , a prefabricated prestressed beam member 2 and a prefabricated bottom slab 19 of a laminated floor. The interior of the prefabricated column member 1 is a hollow steel pipe 4 . The prefabricated composite frame structure also includes cast-in-place concrete in the prefabricated column hollow steel pipe 4 and superimposed surface layer concrete. Among them, the cast-in-place concrete in the prefabricated column hollow steel pipe 4 is poured after the prefabricated column member 1 is transported to the construction site; The prefabricated bottom slab 19 of the laminated floor is placed on the prefabricated prestressed beam member 2 and poured together with the beam-column node area 3 .

[0035] Such as Figures 2(a) to 2(d) , the middle section of the hollow steel pipe 4 of the prefabricated column member 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com