Preparation and application of self-assembly-based porphyrin/alumina composite nano-channel film

An alumina nanometer and nanochannel technology, which is applied in the field of nanomaterials, can solve the problems of cumbersome preparation process of composite nanochannels, high external environment requirements, and ion transport performance to be further improved, and achieves good photoresponsivity and photoreversibility. , the preparation method is simple, easy to operate and achieve the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A structurally symmetrical hourglass-shaped aluminum oxide nanochannel film used in the present invention is prepared by anodic oxidation, and the specific steps are as follows:

[0042] (1) Pretreatment: First, the specification is made of high-purity aluminum ((purity is 99.999%, thickness is 0.1mm) made into a size of 3 × 3cm 2 The aluminum sheet was pre-treated in detergent, acetone, absolute ethanol and high-purity water for 10 minutes respectively to clean the impurities on the aluminum oxide film.

[0043] (2) Electrochemical polishing: in perchloric acid (HClO 4 ) and ethanol (volume ratio 1:4) for electrochemical polishing, the polishing voltage is 17.0V, and the polishing time is three minutes, which makes the aluminum surface smoother and is conducive to the growth of the porous alumina layer.

[0044] (3) The first anodic oxidation: In a low-temperature and constant-temperature circulating water tank, control the reaction temperature to 5°C, use 0.3M oxalic...

Embodiment 2

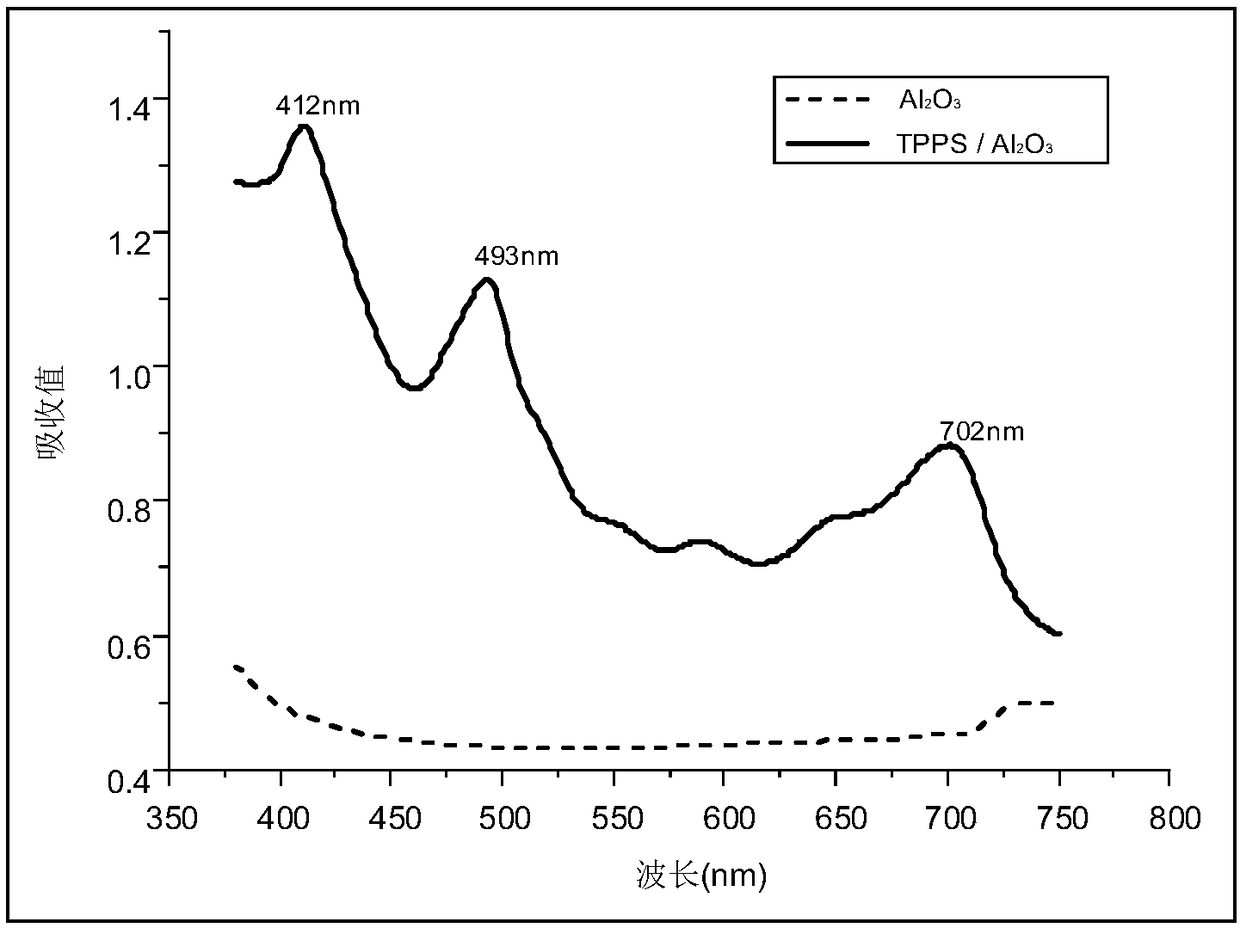

[0052] The preparation of a self-assembled porphyrin / alumina composite nanochannel film provided by the present invention, the porphyrin / alumina composite nanochannel film is abbreviated as TPPS / Al 2 o 3 Composite nanochannel film, the specific implementation steps are as follows:

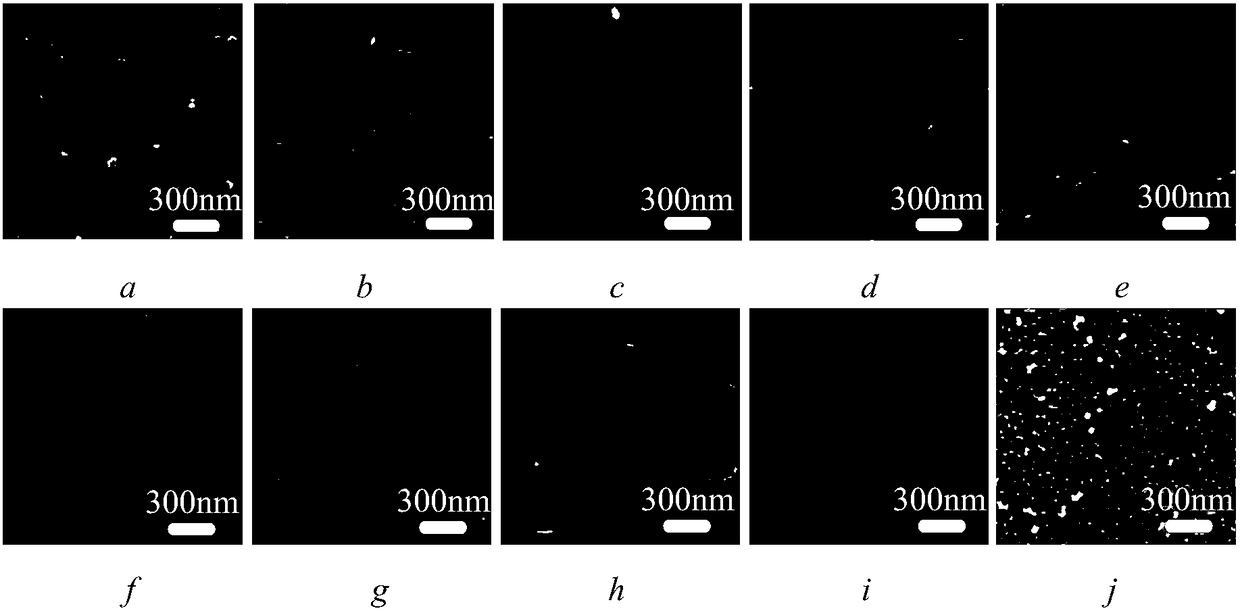

[0053] (1) Using the preparation method provided in Example 1, an hourglass-shaped aluminum oxide nanochannel film with a symmetrical structure was prepared by anodic oxidation, washed and dried naturally, and then used. The self-made hourglass-shaped aluminum oxide nano-channel film with symmetrical structure has a large pore diameter of 35-80 nm on the upper surface and a lower surface, a small pore diameter of 5-20 nm in the middle, and a thickness of 95-100 μm.

[0054] (2) The preparation concentration is 2mM TPPS aqueous solution and 0.5M sodium chloride aqueous solution.

[0055] (3) The TPPS molecule was asymmetrically modified on one side using a self-made groove in the laboratory.

[0...

Embodiment 3

[0061] TPPS / Al 2 o 3 The preparation of the composite nanochannel film, the specific implementation steps are as follows:

[0062] Other steps implemented in this example are the same as the preparation process of Example 2, the difference is that the modification time is 45min, and the obtained TPPS / Al 2 o 3 The pore structure on the upper surface of the composite nanochannel film is as follows: figure 1 (c).

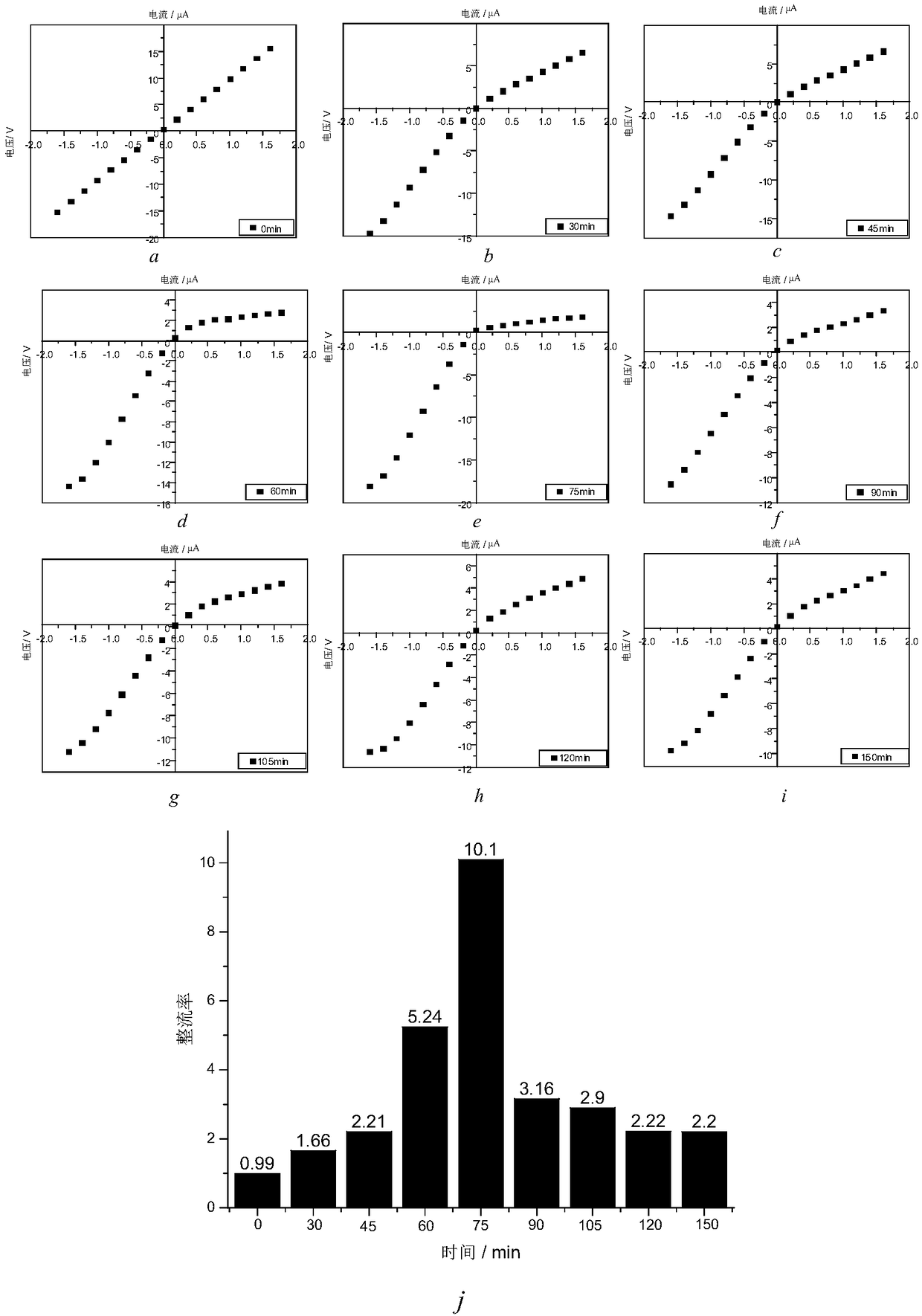

[0063] TPPS / Al 2 o 3 Composite nanochannel thin film is used for ion transport performance test, and test condition is identical with the application condition of embodiment 2, and the I-V curve that obtains is as follows image 3 (c) shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com