Equipment for preparing mineral wool and preparation method thereof

A technology of rock wool and equipment, which is applied in the field of rock wool preparation, can solve the problems of electrode needs, large heat loss of transformers, and large heat loss, and achieve the effects of improving production efficiency and quality, reasonable process layout, and good market value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

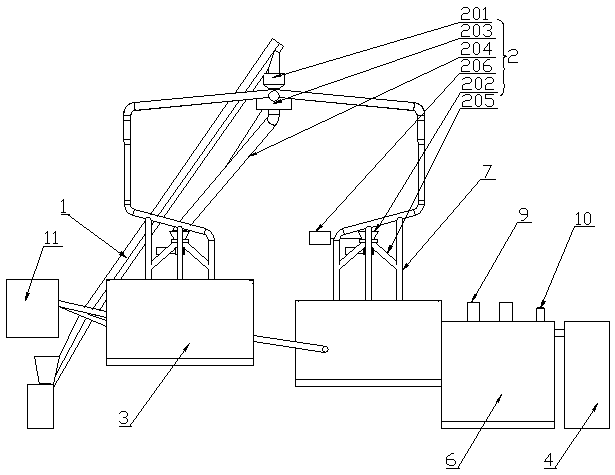

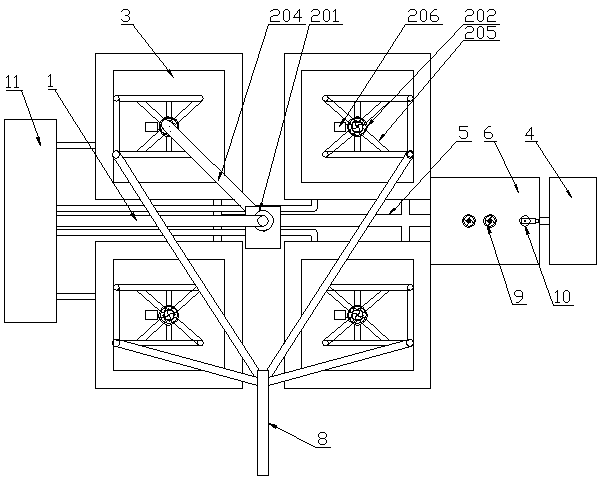

[0035] The method for preparing rock wool is carried out by using the above-mentioned equipment for preparing rock wool. Specific Example 1 includes the following steps:

[0036] Step 1: Liquid slag is added to the heating furnace 3 through the liquid storage tank 11, while the additives are added to the heating furnace 3 through the material dispersion device 2;

[0037] Step 2: After rapid heating and reaction in the heating furnace 3, new liquid materials are generated, and CO2, flue gas and dust are discharged and treated separately;

[0038] Step 3: Different heating furnaces 3 flow out the liquid material in turn, and flow into the homogenization speed control furnace 6 through the overflow pipe 5. After mixing, temperature adjustment, stirring, and homogenization in the homogenization speed control furnace 6, the corresponding temperature, Viscosity and acidity coefficient require new liquid materials to produce CO2, flue gas and dust discharge, and the CO2, flue gas and dust ...

Embodiment 2

[0043] The method for preparing rock wool is performed by using the above-mentioned equipment for preparing rock wool. Specific Example 2 includes the following steps:

[0044] Step 1: Solid slag and additives are added to the heating furnace 3 through the material dispersion device 2;

[0045] Step 2: After rapid heating and reaction in the heating furnace 3, new liquid materials are generated, and CO2, flue gas and dust are discharged and treated separately;

[0046] Step 3: Different heating furnaces 3 flow out the liquid material in turn, and flow into the homogenization speed control furnace 6 through the overflow pipe 5. After mixing, temperature adjustment, stirring, and homogenization in the homogenization speed control furnace 6, the corresponding temperature, Viscosity and acidity coefficient require new liquid materials to produce CO2, flue gas and dust discharge, and the CO2, flue gas and dust produced in step 2 are combined for treatment; while the temperature is kept in...

Embodiment 3

[0051] The method for preparing rock wool is performed by using the above-mentioned equipment for preparing rock wool. Specific embodiment 3 includes the following steps:

[0052] Step 1: The stone is added to the heating furnace 3 through the material dispersion device 2;

[0053] Step 2: After rapid heating and reaction in the heating furnace 3, new liquid materials are generated, and CO2, flue gas and dust are discharged and treated separately;

[0054] Step 3: Different heating furnaces 3 flow out the liquid material in turn, and flow into the homogenization speed control furnace 6 through the overflow pipe 5. After mixing, temperature adjustment, stirring, and homogenization in the homogenization speed control furnace 6, the corresponding temperature, Viscosity and acidity coefficient require new liquid materials to produce CO2, flue gas and dust discharge, and the CO2, flue gas and dust produced in step 2 are combined for treatment; while the temperature is kept in the homogeni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com