Colored coating coil material capable of being conveniently fixed and installed

A color coating and roll material technology, which is applied to layered products, metal layered products, building components, etc., can solve the problems of poor thermal insulation effect, difficult installation process, difficult wiring, etc., and achieve good thermal insulation effect , Easy and fast installation, convenient wiring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

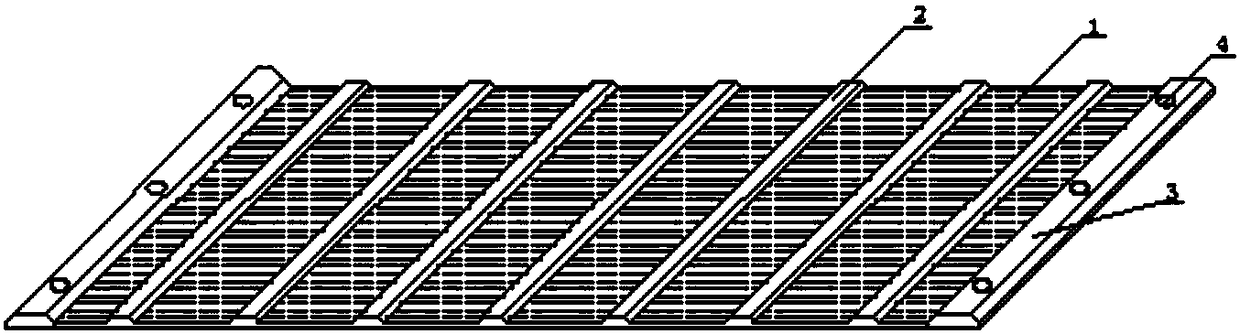

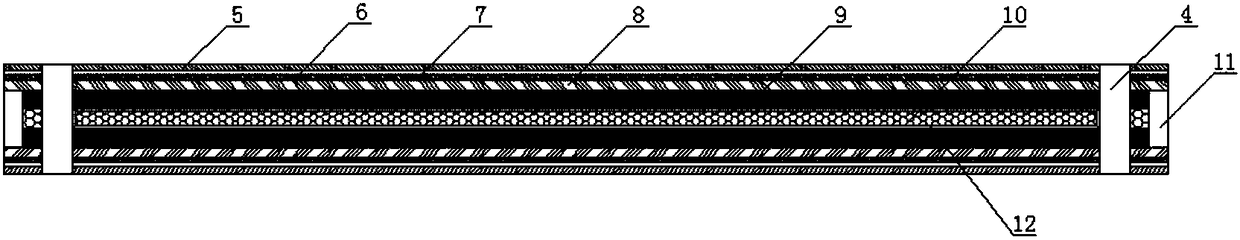

[0016] refer to Figure 1-2 , a color-coated coiled material that is convenient for fixed installation, comprising a coiled material plate 1, the upper end of the coiled material plate 1 is provided with a threading groove 2, and the left and right ends of the coiled material plate 1 are equipped with end connecting plates 3, and the ends are connected The inside of the plate 3 is provided with a fixing hole 4, and the coiled material plate 1 includes an outer paint coating 5, a primer 6, a chemical conversion coating 7, a galvanized layer 8, a cold-rolled steel plate 9, a heat insulating element 10, a sealing element 11 and an insulating element. Empty layer 12, pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com