Phthaphthalonitrile resin prepreg, composite material and preparation method of composite material

A technology of phthalonitrile resin and phthalonitrile, which is applied in the fields of phthalonitrile resin prepreg, composite material and preparation thereof, can solve the difficulty of resin viscosity control, is not suitable for industrial production of complex components, etc. problems, to achieve excellent comprehensive performance, easy to achieve, and ensure product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

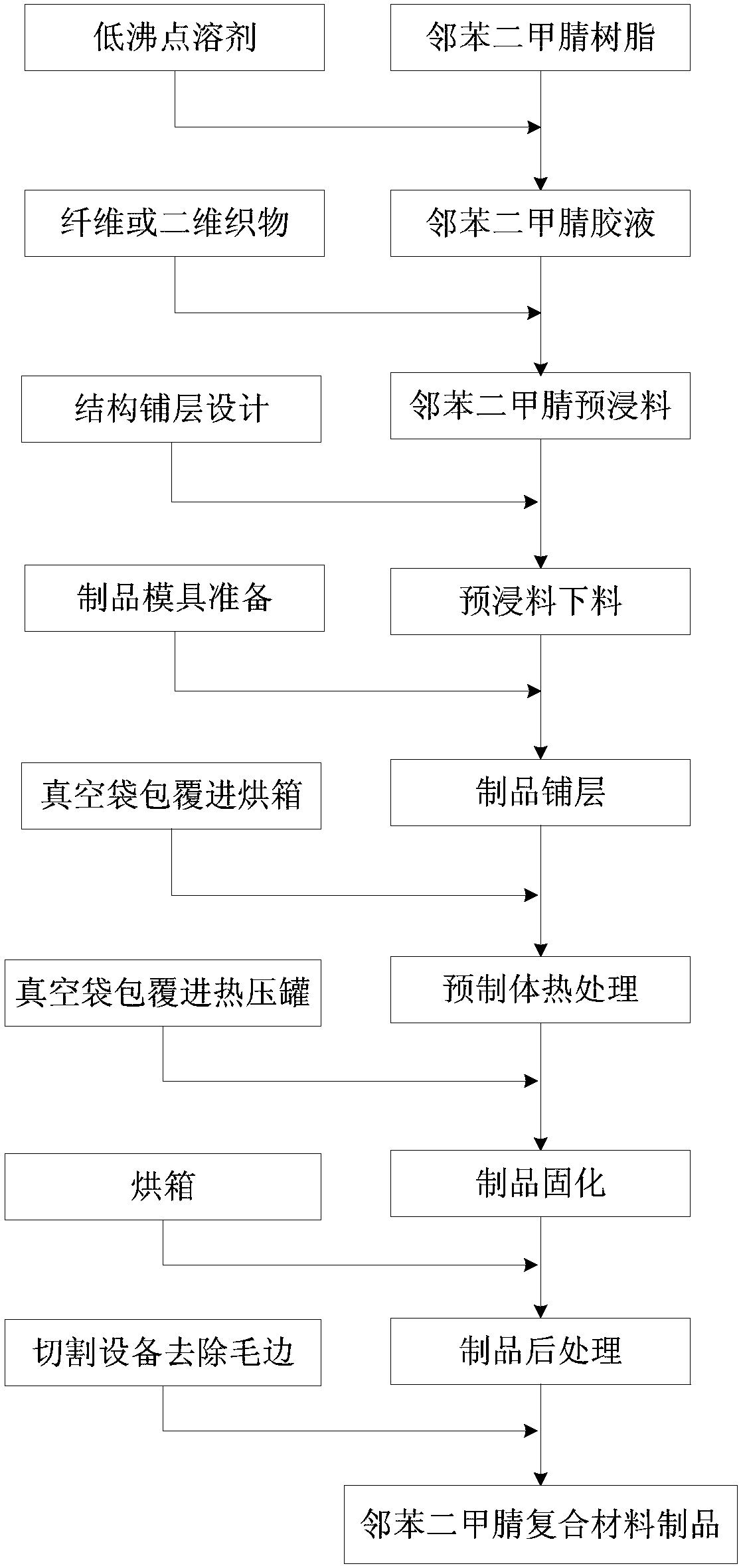

[0047] The phthalonitrile composite material of the present invention is prepared from the above-mentioned phthalonitrile resin prepreg, such as figure 1 Shown is the phthalonitrile prepreg preparation and curing process flow chart of the present invention, the specific preparation method of the phthalonitrile composite material of the present invention comprises the following steps:

[0048] (1) Preparation of phthalonitrile prepreg

[0049] The phthalonitrile resin is diluted with a low-boiling point solvent at room temperature, and evenly brushed on the fiber cloth in proportion, and the number of brushing is ≥ 2 times, and the prepared prepreg is fully allowed to stand at room temperature until the volatile content (low Boiling point solvent) mass percentage content≤4%, to ensure that the low boiling point solvent in the prepreg is fully volatilized.

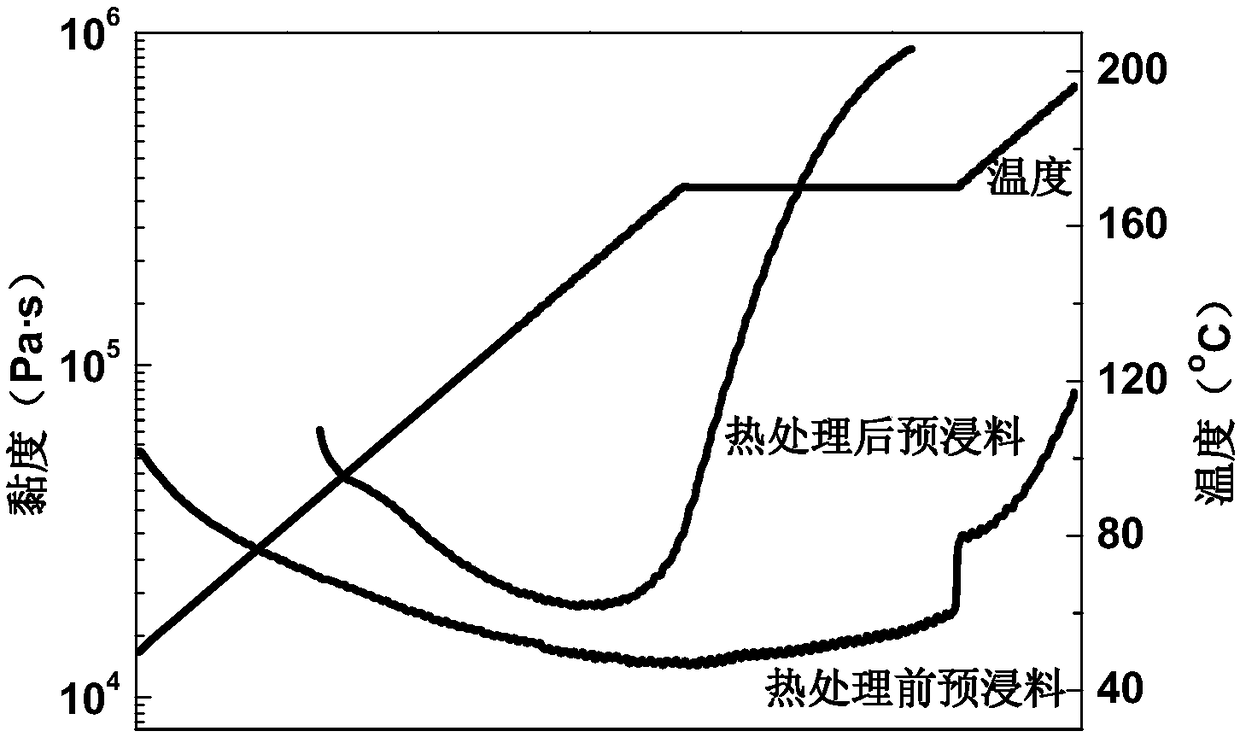

[0050] (2) Phthalonitrile prepreg preheating treatment

[0051] Lay the phthalonitrile prepreg to the desired thickness ac...

Embodiment 1

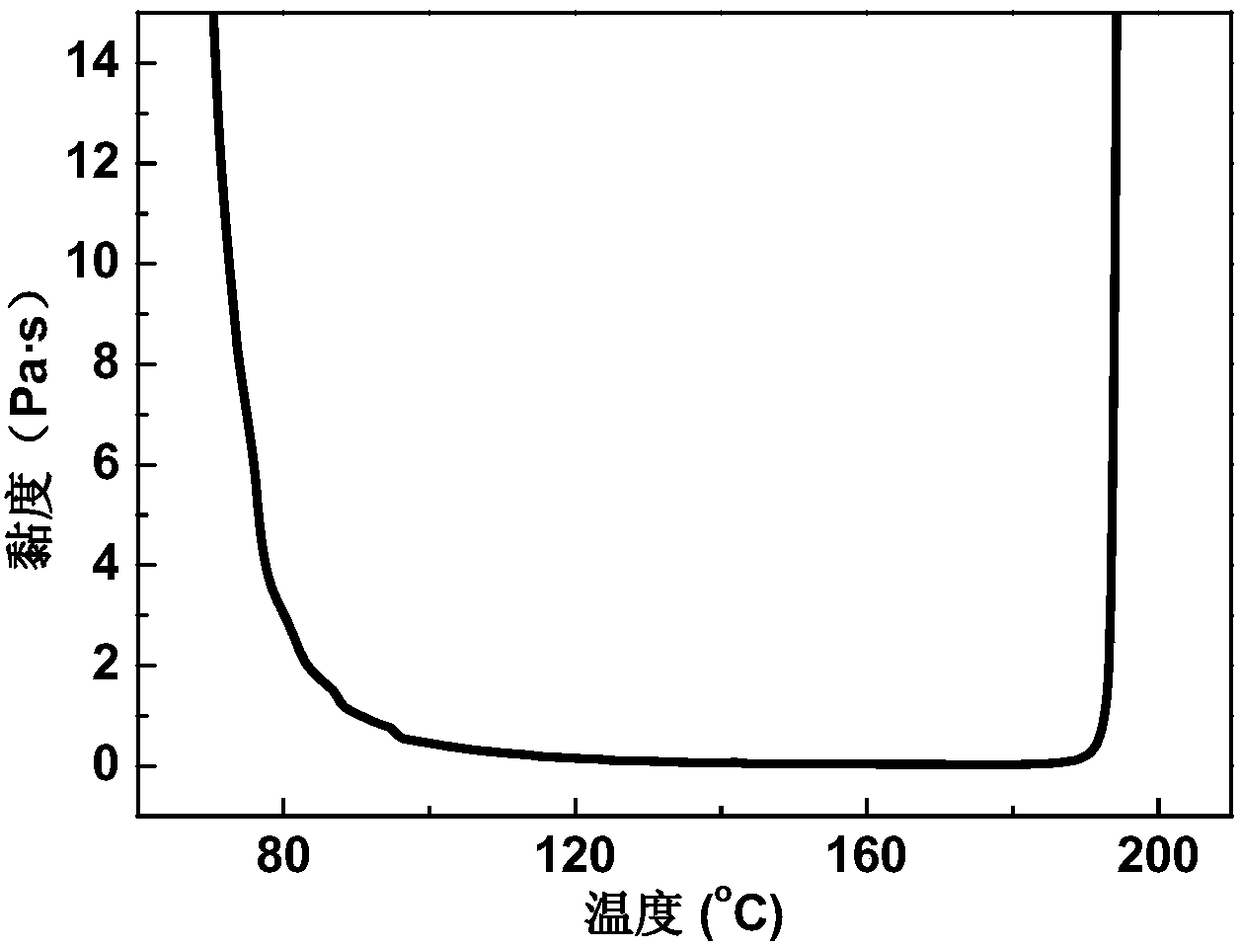

[0058] A phthalonitrile resin prepreg, which is prepared by mixing phthalonitrile resin and acetone in a mass ratio of 100:120 to make a glue solution, and then uniformly coating the glue solution on 120 parts of carbon fiber cloth to make a prepreg Dipping material, the number of times of brushing is 2 times, and it is fully aired until the volatile content in it drops below 4%. Wherein the viscosity temperature rise curve of phthalonitrile resin is as follows figure 2 As shown, the viscosity is less than 1Pa·s in a wide temperature range. The molding steps of the phthalonitrile composite material are as follows: (1) Prepreg is cut according to the requirements, and 8 layers of carbon cloth are used to lay layers along the shape of the mold; (2) The product is covered with 250°C-resistant auxiliary materials and vacuum bags ;(3) Put it in an oven and heat it to 170°C for 1h; (4) Put the product into an autoclave for curing under the condition of vacuuming, the curing system...

Embodiment 2

[0060] A phthalonitrile resin prepreg, which is prepared by mixing phthalonitrile resin and acetone at a mass ratio of 100:185 to make a glue solution, which is then poured into a glue tank, and wet-process yarn-discharging equipment is used for non-toxic For the preparation of weft prepreg, the resin content is controlled at 44±4% of the total weight of the prepreg; another phthalonitrile resin prepreg is composed of phthalonitrile resin and acetone in a mass ratio of 100 : 120 to make a glue solution, and then evenly coat the glue solution on 120 parts of carbon fiber fabric cloth to make a prepreg, and the number of times of painting is 2 times. The prepreg is fully aired at room temperature until the volatile content in it falls below 4%. The forming steps of the phthalonitrile composite material are as follows: (1) The phthalonitrile carbon fiber non-weft prepreg and the fabric cloth prepreg are respectively cut according to the requirements, according to [carbon cloth / 90...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com