An atomization dedusting system and method for an industrial plant

A technology for dust removal systems and industrial plants, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as endangering the health of workers, increasing enterprise cost investment, and large investment, achieving high energy utilization, Easy to promote, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

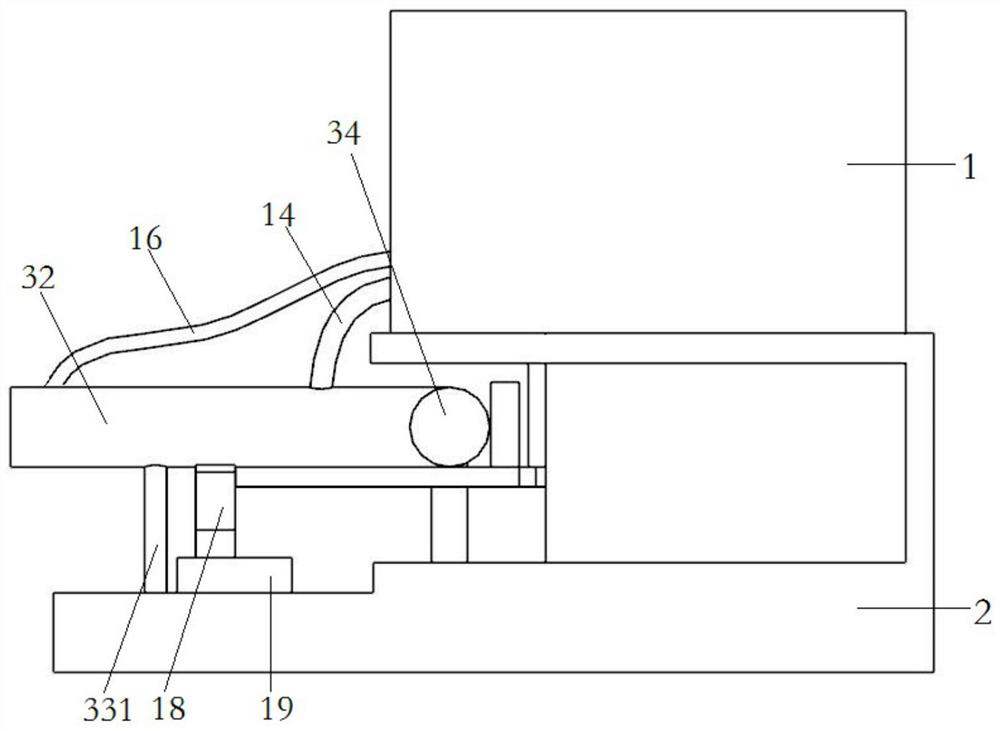

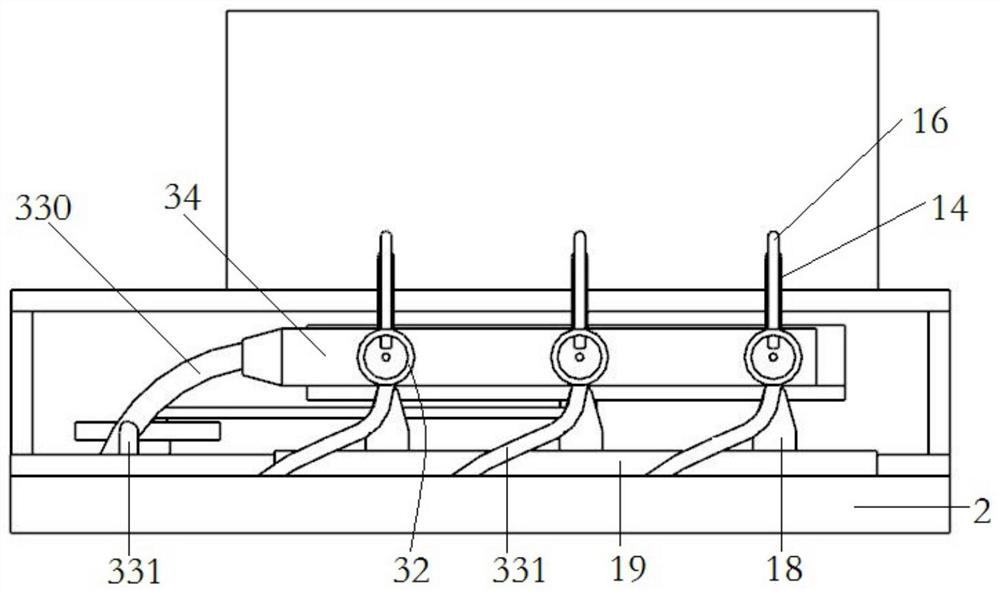

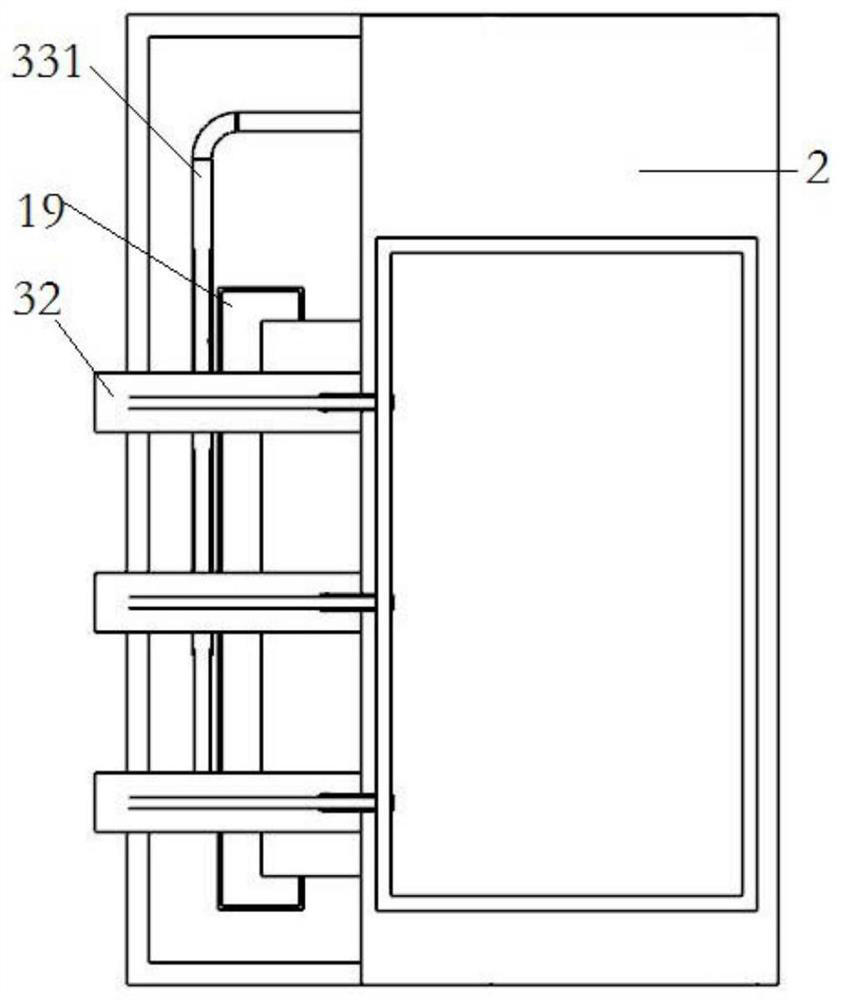

[0031] as attached figure 1 to attach Figure 5 As shown, an atomization and dust removal system for an industrial plant includes a water tank 1, a base 2, a swing device 11 and an atomization device 3, the base 2 is arranged on the top of the plant, and the base 2 is placed horizontally U-shaped structure, the swing device 11 is arranged in the U-shaped cavity 12 on the base 2, the swing device 11 includes a swing plate 10, the swing plane of the swing plate 10 is a horizontal plane, and the swing plate 10 reciprocates Swing in the U-shaped cavity 12, the swing plate 10 is provided with an atomizing device 3, the atomizing device 3 is arranged on the opening side of the U-shaped cavity, and the mist outlet extends to the outside of the U-shaped cavity, the The atomizing device 3 swings back and forth following the oscillating plate 10, and the mist outlet 30 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com