Manufacturing method for polypyrrole/conductive carbon cloth combined electrode, and application thereof

A composite electrode, conductive carbon cloth technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve problems such as poor cycle stability and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Weigh 0.56g NaClO 4 Dissolve in 20mL deionized water and stir until fully dissolved.

[0028] (2) Add 1mL of pyrrole monomer to the above solution and stir thoroughly for 60min to prepare a solution containing 0.2M NaClO 4 And 5% (V / V) PPy electrolyte. figure 1 b is the SEM image of the sample.

[0029] (3) In the three-electrode system controlled by the electrochemical workstation, the constant potential method was selected, and the conductive carbon cloth was used as the working electrode, the platinum electrode was used as the counter electrode, and the saturated calomel electrode was used as the reference electrode, and placed in the above electrolyte. Set the initial voltage to 0.8V, and the electrochemical deposition time to 2min. After the deposition, it was rinsed repeatedly with deionized water and left to dry in a natural environment.

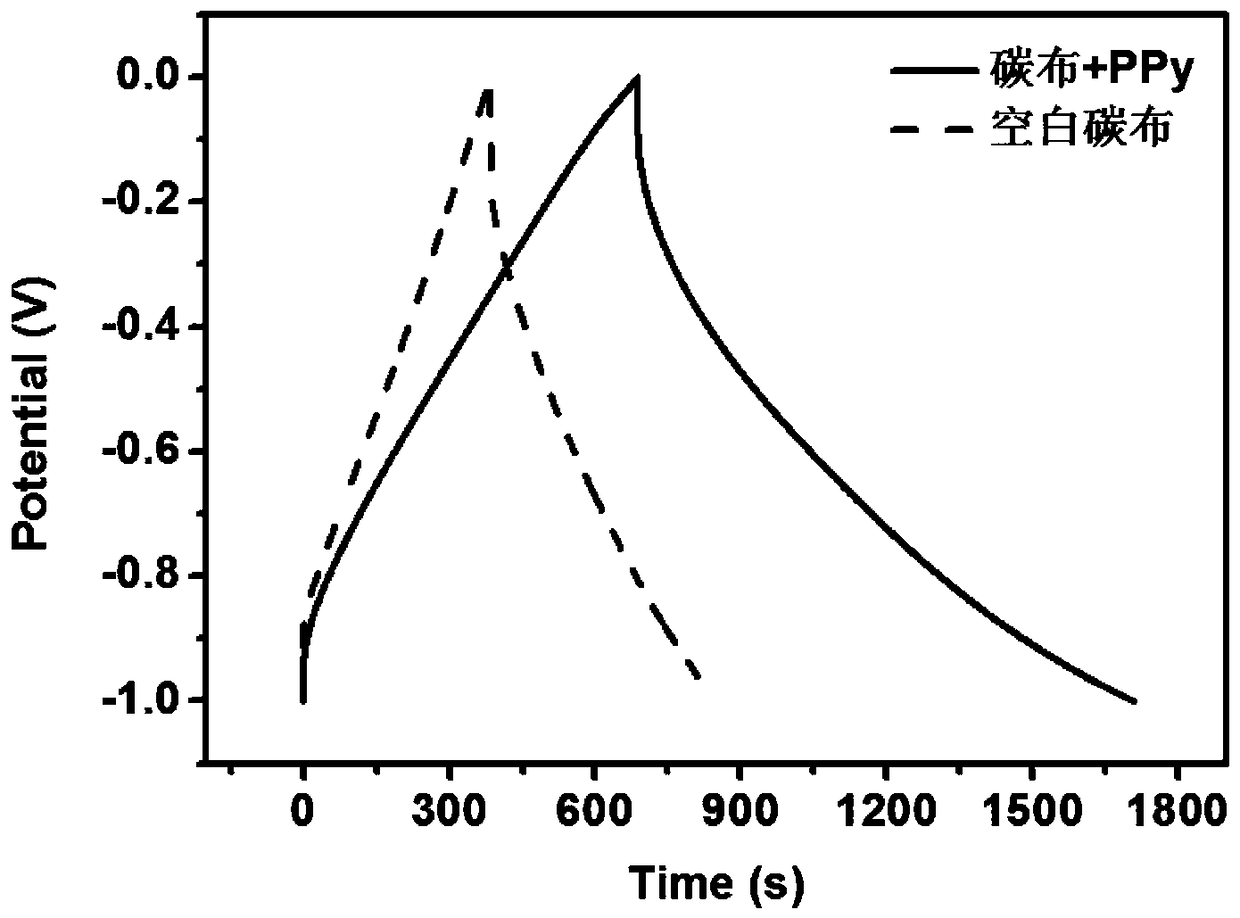

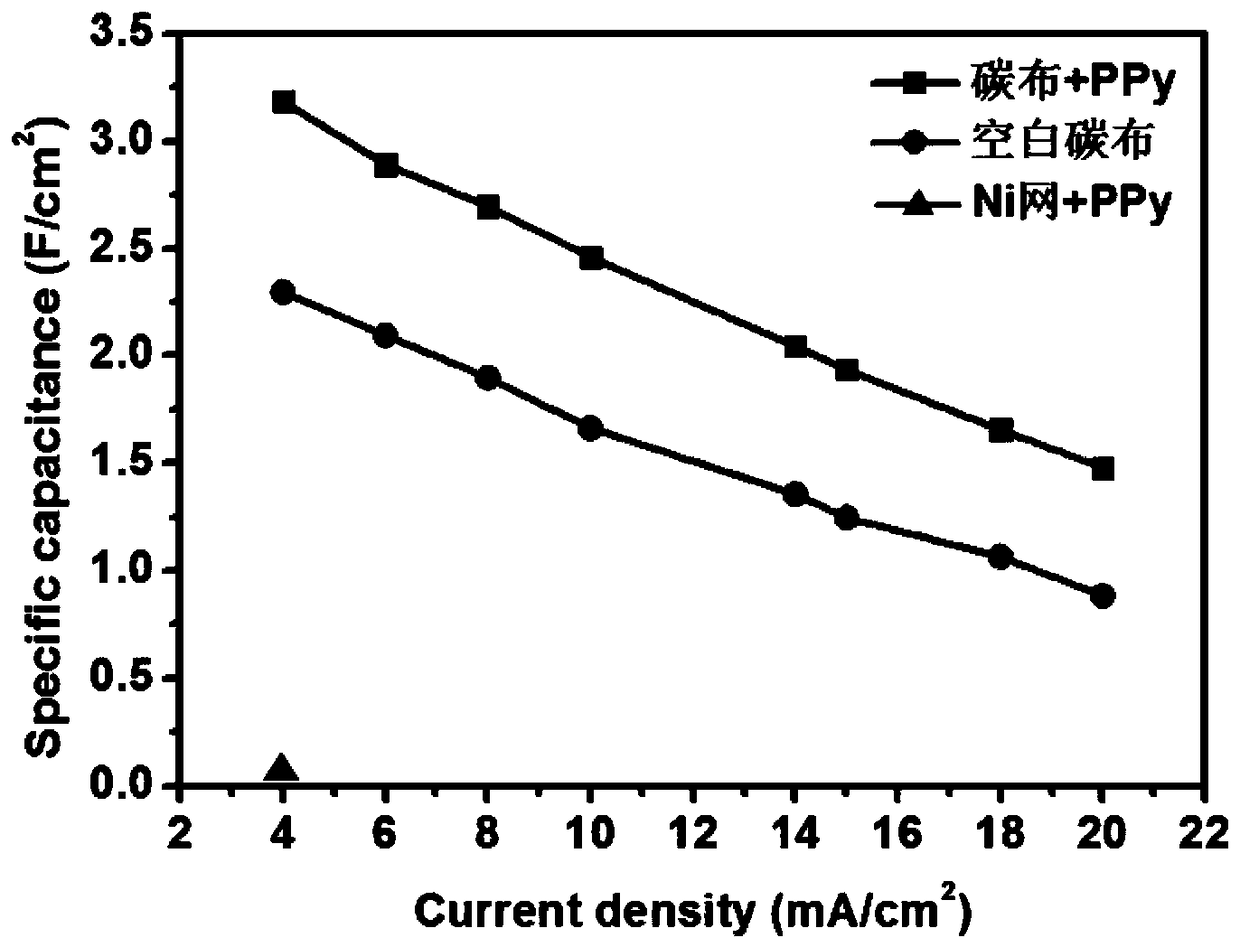

[0030] (4) Use this electrode as the negative electrode, use the platinum electrode as the counter electrode, and the...

Embodiment 2

[0033] (1) Weigh 0.56g NaClO 4 Dissolve in 20mL deionized water and stir until fully dissolved.

[0034](2) Add 1mL of pyrrole monomer to the above solution and stir thoroughly for 60min to prepare a solution containing 0.2M NaClO 4 And 5% (V / V) PPy electrolyte. figure 1 b is the SEM image of the sample.

[0035] (3) In the three-electrode system controlled by the electrochemical workstation, the constant potential method was selected, and the conductive carbon cloth was used as the working electrode, the platinum electrode was used as the counter electrode, and the saturated calomel electrode was used as the reference electrode, and placed in the above electrolyte. Set the initial voltage to 0.8V, and the electrochemical deposition time to 6min. After the deposition, it was rinsed repeatedly with deionized water and left to dry in a natural environment.

[0036] (4) Use this electrode as the negative electrode, use the platinum electrode as the counter electrode, and the ...

Embodiment 3

[0039] (1) Weigh 0.56g NaClO 4 Dissolve in 20mL deionized water and stir until fully dissolved.

[0040] (2) Add 1mL of pyrrole monomer to the above solution and stir thoroughly for 60min to prepare a solution containing 0.1M NaClO 4 And 5% (V / V) PPy electrolyte. figure 1 b is the SEM image of the sample.

[0041] (3) In the three-electrode system controlled by the electrochemical workstation, the constant potential method was selected, and the conductive carbon cloth was used as the working electrode, the platinum electrode was used as the counter electrode, and the saturated calomel electrode was used as the reference electrode, and placed in the above electrolyte. Set the initial voltage to 0.8V, and the electrochemical deposition time to 2min. After the deposition, it was rinsed repeatedly with deionized water and left to dry in a natural environment.

[0042] (4) Use this electrode as the negative electrode, use the platinum electrode as the counter electrode, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com