Desulfurization and denitrification effect control system in intelligent flue gas treatment

A flue gas treatment, desulfurization and denitrification technology, applied in general control system, control/regulation system, electrical program control, etc., can solve the problem that the separator cannot achieve the oxygen separation effect, the effect is poor, and it cannot provide a basis for reasonable governance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0115] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

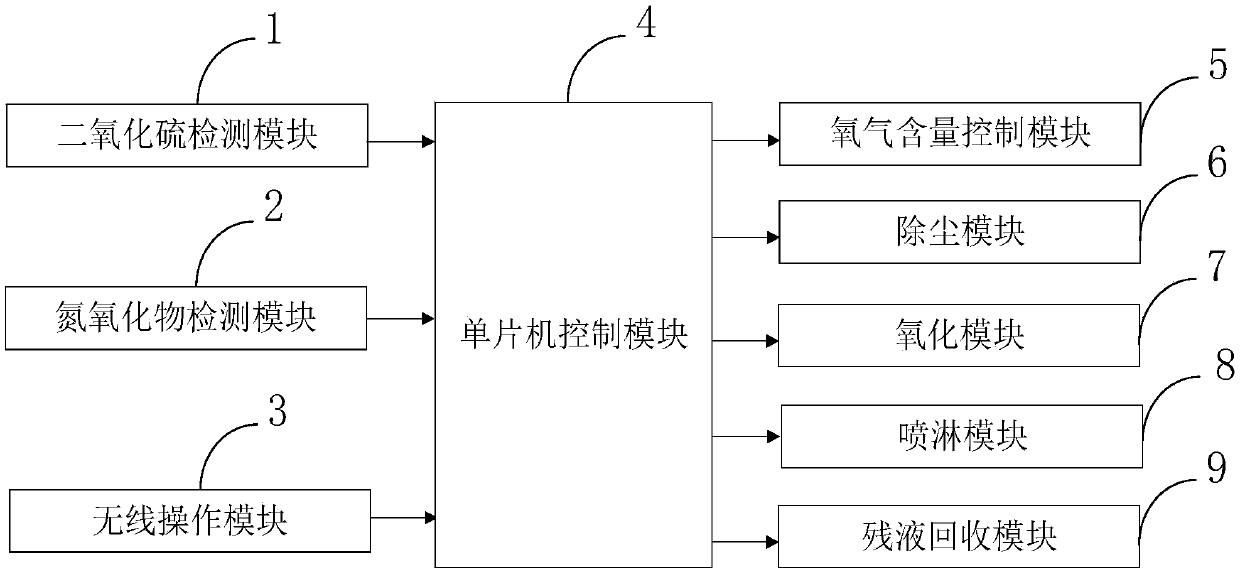

[0116] Such as figure 1 As shown, the control system for the desulfurization and denitration effect in the intelligent flue gas treatment provided by the embodiment of the present invention includes: a sulfur dioxide detection module 1, a nitrogen oxide detection module 2, a wireless operation module 3, a single-chip microcomputer control module 4, and an oxygen content control module 5 , dust removal module 6, oxidation module 7, spray module 8, residual liquid recovery module 9.

[0117] The sulfur dioxide detection module 1 is connected with the single-chip microcomputer control module 4, and is used for detecting the sulfur dioxide content in the flue gas;

[0118] The nitrogen oxide detection module 2 is connected with the single-chip microcomputer cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com