Anti-locking soil body frost heaving test sample tube

A technology of frost heave test and sample cylinder, which is applied in the field of frozen soil physics frost heave test, which can solve the problems of lack of authenticity of frost heave data and unfavorable prior control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further explained by specific examples below.

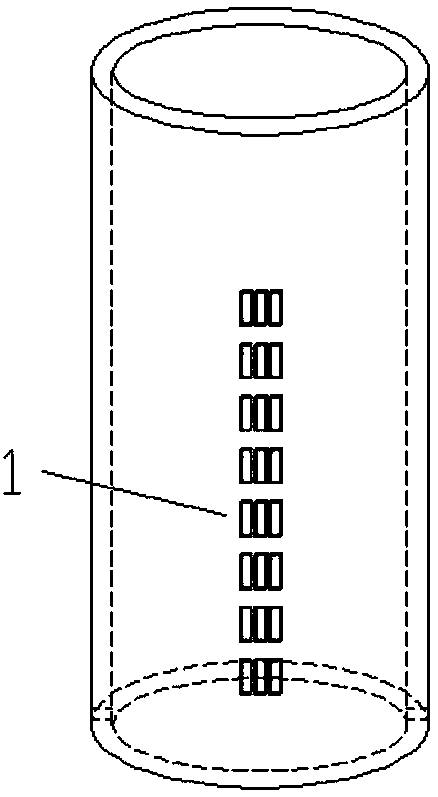

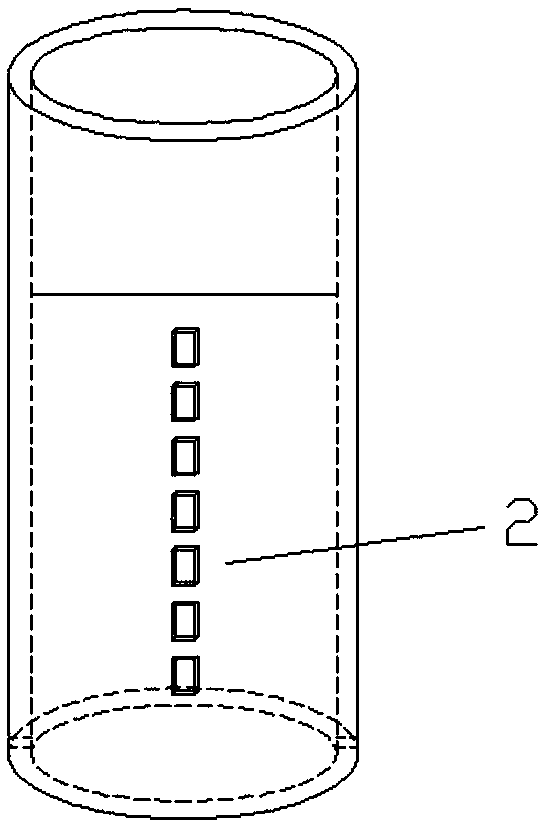

[0026] Before use, apply vaseline on the inner wall of the outer cylinder and the outer wall of all the structures of the inner cylinder, then put the lower structure of the inner cylinder into the outer cylinder, correspond to the position of the insertion hole of the sensor, fix the lower structure of the inner cylinder and the outer cylinder with fixing bolts, and then put the inner cylinder lower structure into the outer cylinder. The middle structure of the cylinder is installed according to the concave and convex openings. The important thing is that the position of the sensor insertion hole must be corresponding. Finally, put the upper structure of the inner cylinder into the outer cylinder and fix it with fixing bolts.

[0027] After assembling the test cylinder, apply vaseline inside it, and make soil samples in it. After the curing is completed under the test maintenance requirements,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com