Combination type processing process integrated measurement method based on vision laser

A technology of processing process and measurement method, applied in the field of geometric measurement, can solve problems such as poor adaptability of processing site and insufficient measurement accuracy, and achieve the effects of high measurement range robustness, high measurement accuracy, and measurement intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

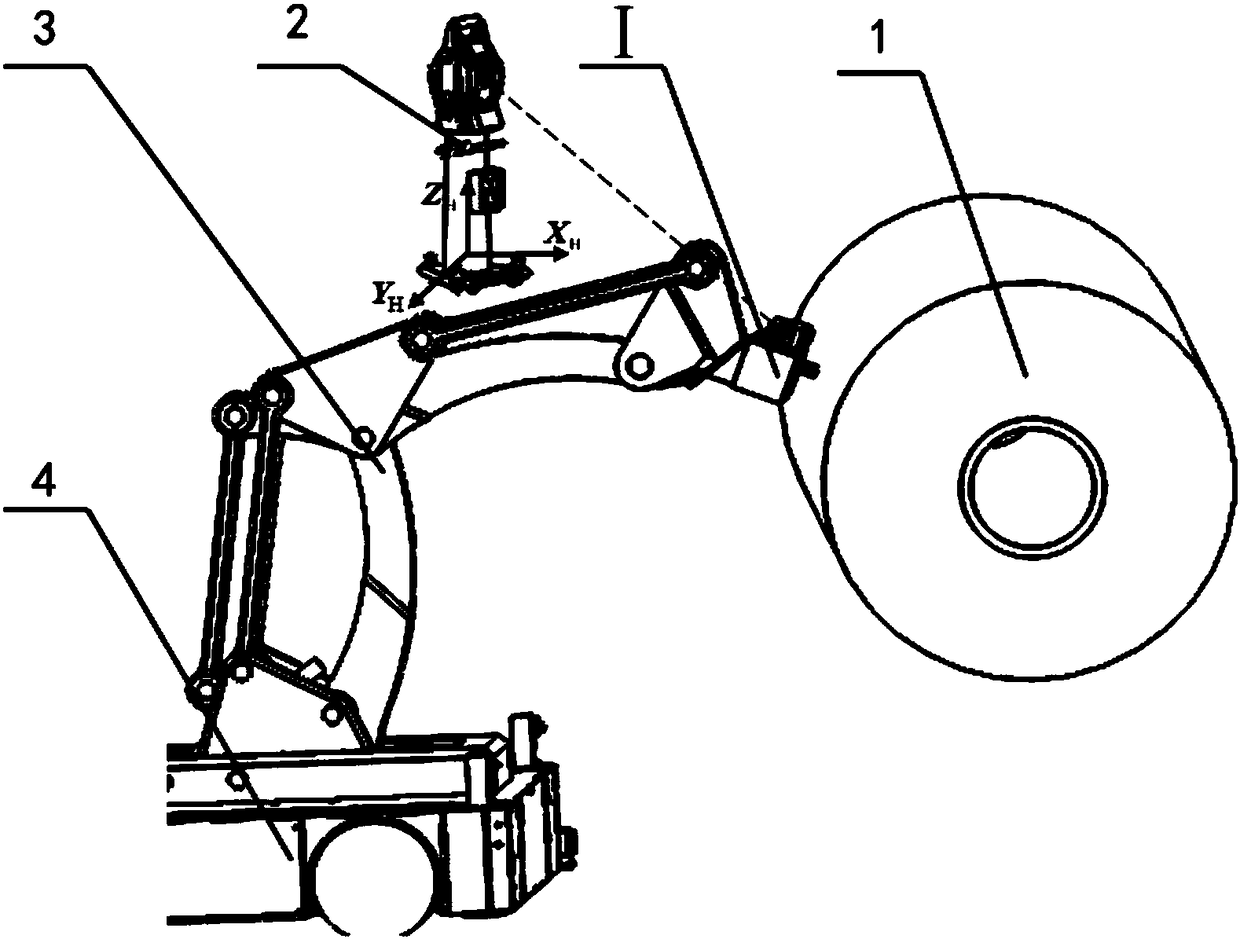

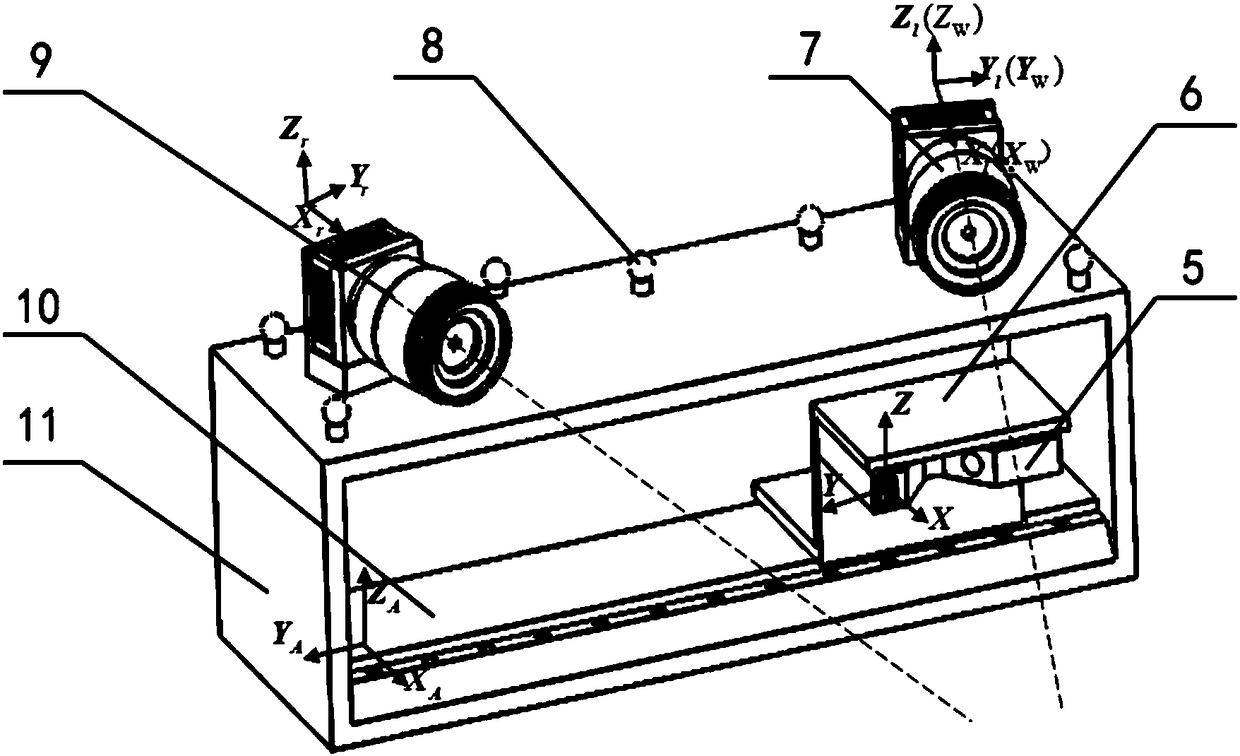

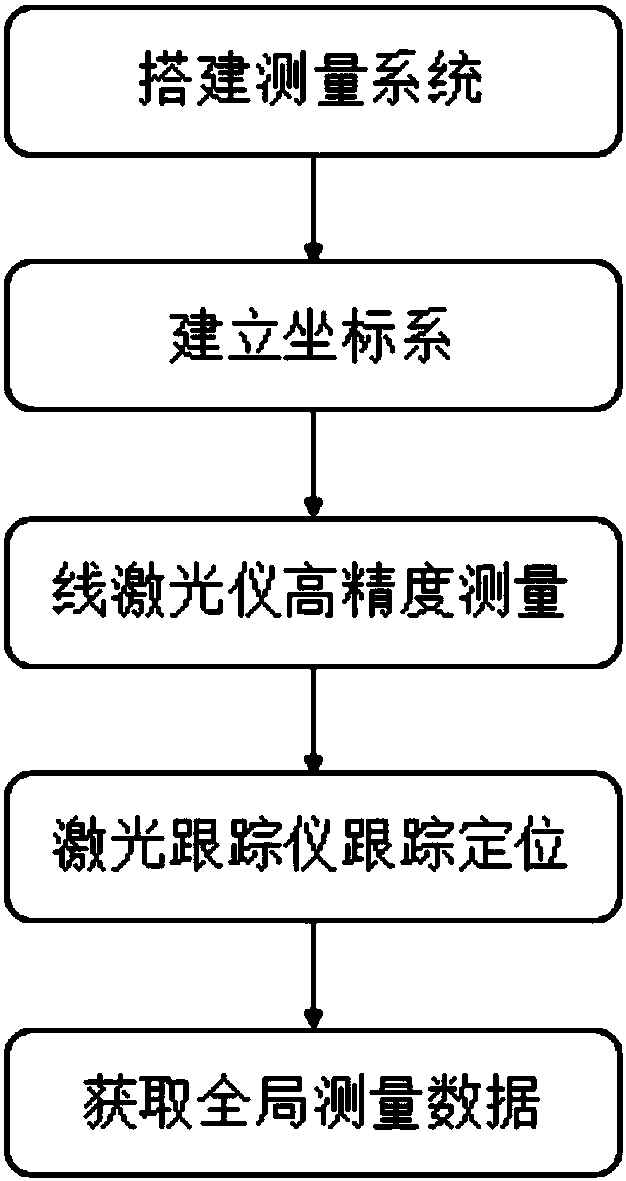

[0030] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0031] The line laser scanner 5 used in this embodiment is the LJ-V7060 type measuring instrument of Keyence Corporation, and its repeatability in the X-axis direction is 5 μm, and the repeatability in the Z-axis direction is 0.4 μm. The electric control platform 10 adopts the M521.DD model precision mobile platform of PI Company, and its repeated positioning accuracy is 0.2 μm. The laser tracker 2 is AT960 of Leica Company, and its measurement uncertainty is ±15 μm+6 μm / m. The models of cameras 7 and 9 in the binocular vision system are vieworks VC‐12MC‐M / C 65 cameras, resolution: 4096×3072, image sensor: CMOS, frame rate: full frame, up to 64.3fps. The lens model is EF16‐35mmf / 2.8LIIUSM, lens focal length: f=16‐35, APS focal length: 25.5‐52.5, aperture: F2.8. The shooting conditions are as follows: the pixel of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com