Rolling bearing lubricating method

A rolling bearing and lubricating grease technology, which is applied in the field of bearing lubrication, can solve problems such as scrapping, affecting bearing performance, and low-temperature tempering of bearings, and achieve the effects of avoiding excessive use, ensuring work performance, and improving work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

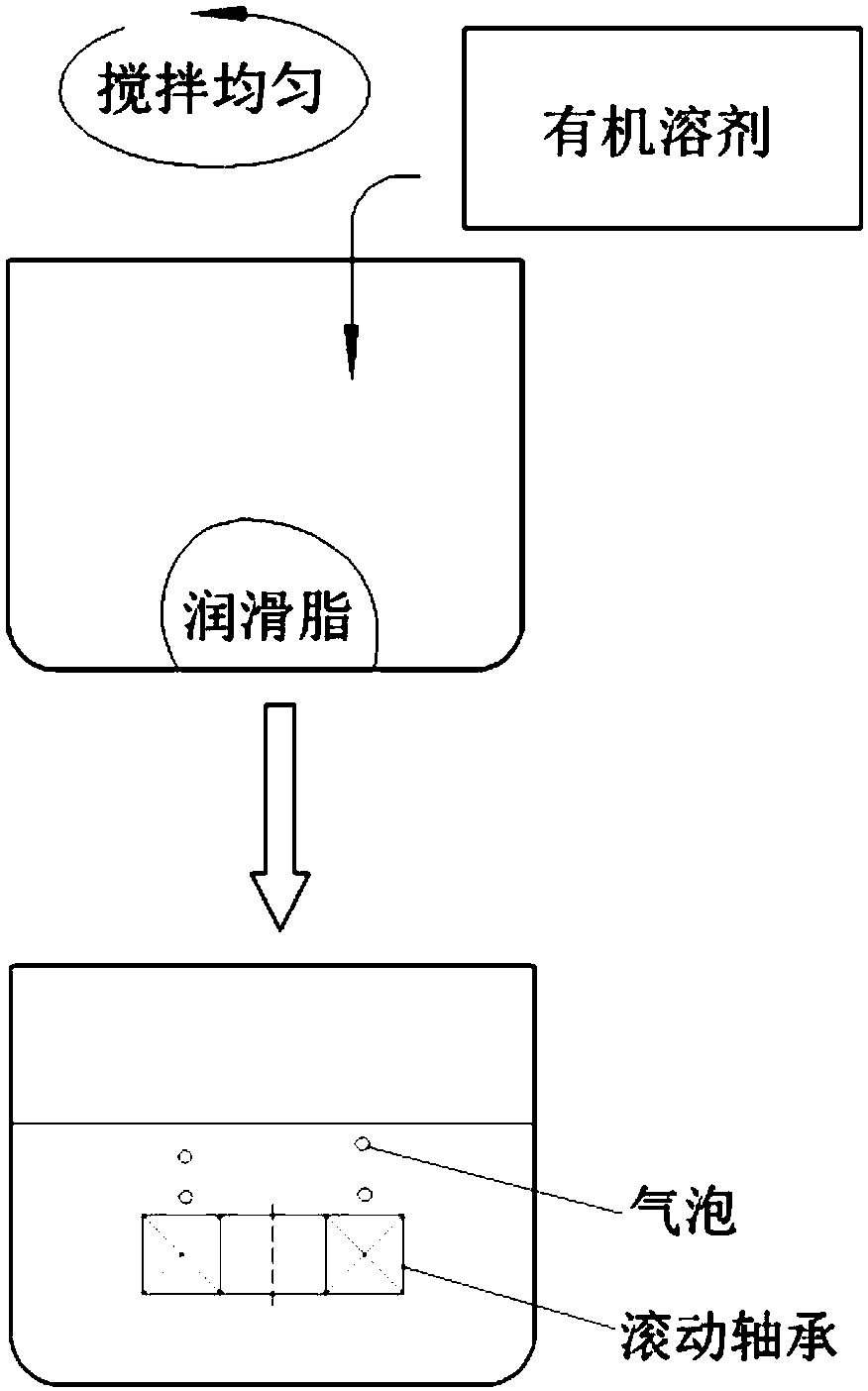

[0041] see figure 1 The flow shown is for rolling bearing lubrication, and the specific implementation is as follows:

[0042] 1), 200g of low-temperature lubricating grease (Sinopec Lubricating Oil Co., Ltd., Great Wall 7008 aviation grease) and 500mL of petroleum ether (Tianjin Tiantai Fine Chemical Co., Ltd., 90# solvent oil, Cas: 8032-32-4, boiling (range 60~90℃) to prepare a grease solution. During the preparation process, fully stir, stand for observation, and remove impurities and flocculent undissolved grease.

[0043] 2) Place the pre-cleaned sealed rolling bearing in the grease solution and stir the bearing until no bubbles appear on the liquid surface to ensure sufficient distribution of the solution in the sealing cover.

[0044] 3) Take out the bearing, put one side of it on a smooth and clean place, such as a glass plate, and let it dry or use a blower to dry it.

[0045] 4) Clean the grease on the bearing surface to avoid excessive accumulation of grease on no...

Embodiment 2

[0050] 1), 200g of low-temperature lubricating grease (Sinopec Lubricating Oil Co., Ltd., Great Wall 7008 aviation grease) and 500mL of petroleum ether (Tianjin Tiantai Fine Chemical Co., Ltd., 90# solvent oil, Cas: 8032-32-4, boiling (range 60~90℃) to make a grease solution. During the preparation process, fully stir, stand for observation, and remove impurities.

[0051] 2) Place the pre-cleaned unsealed rolling bearing in the grease solution, and complete the operation after fully immersing it.

[0052] 3) Take out the bearing, place it in a clean place, and let it dry in the air or with a blower.

[0053] 4) Clean the grease on the bearing surface to avoid excessive accumulation of grease on non-friction parts and complete the lubrication process. Taking the non-sealed deep groove ball bearing 6006 as an example, about 0.22g of grease can be adhered inside the bearing after completing the above steps

[0054] 5) If the amount of bearing grease does not meet the requireme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com