Ammonia concentration distribution test device

A technology of distribution testing and ammonia gas concentration, which is applied to the electronic control of exhaust gas treatment devices, diagnostic devices of exhaust gas treatment devices, and exhaust gas treatment, etc. problems, to achieve the effect of convenient operation, high measurement accuracy and comprehensive measurement data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

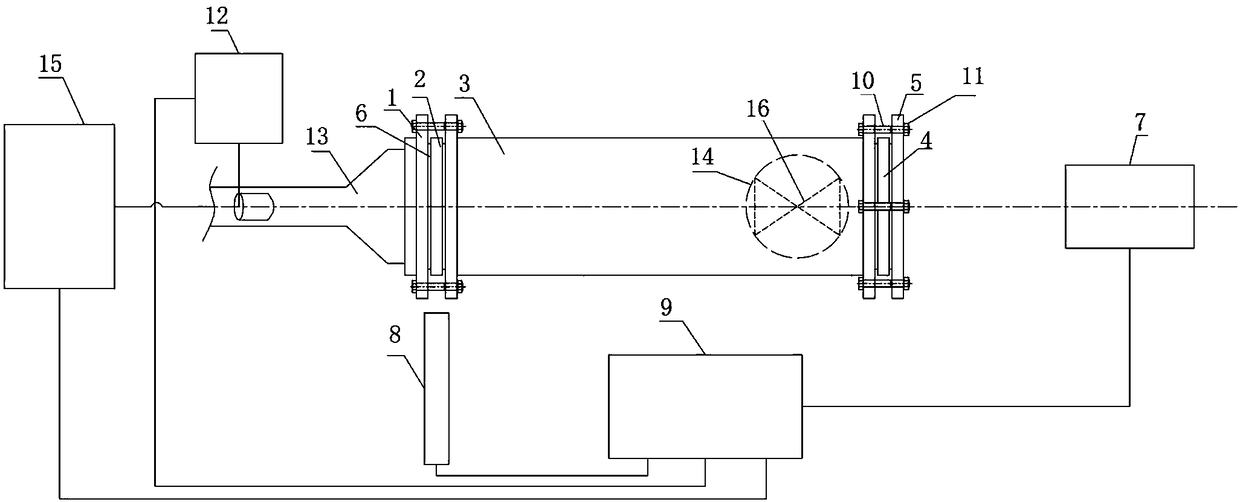

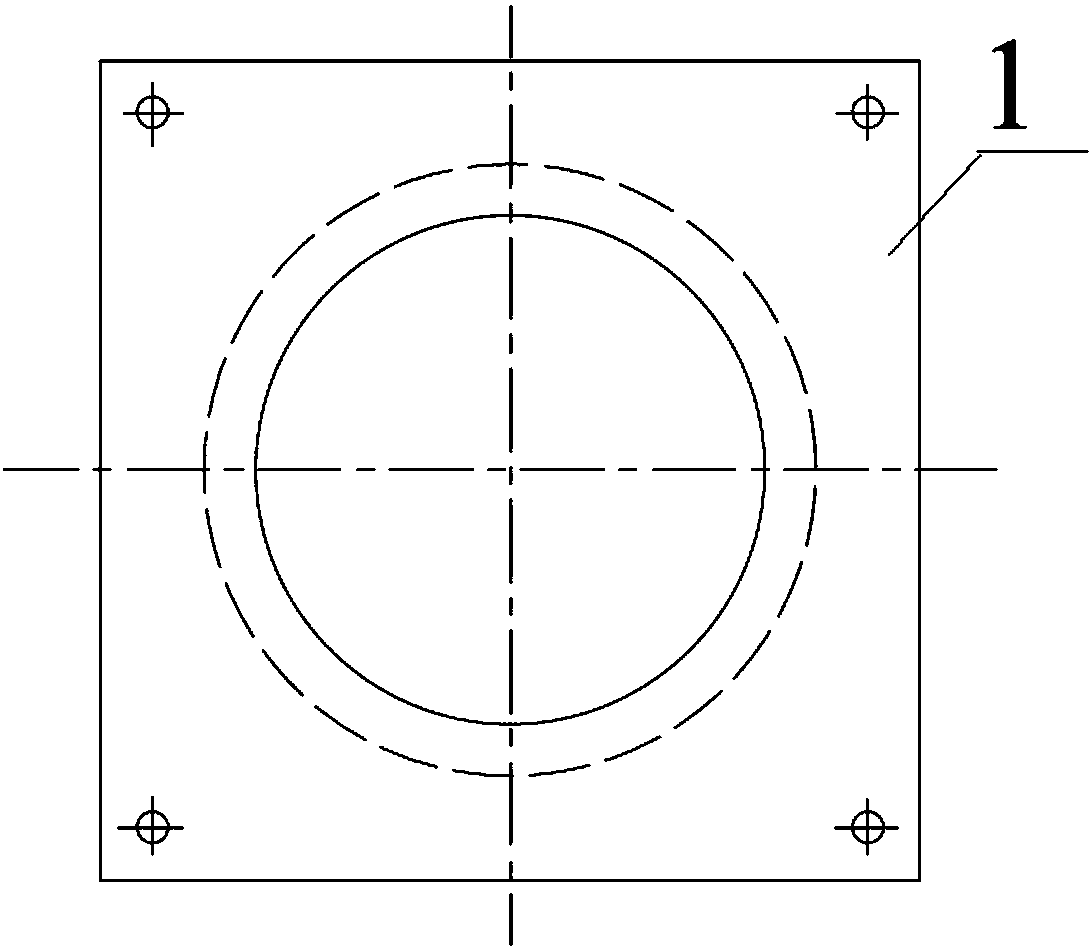

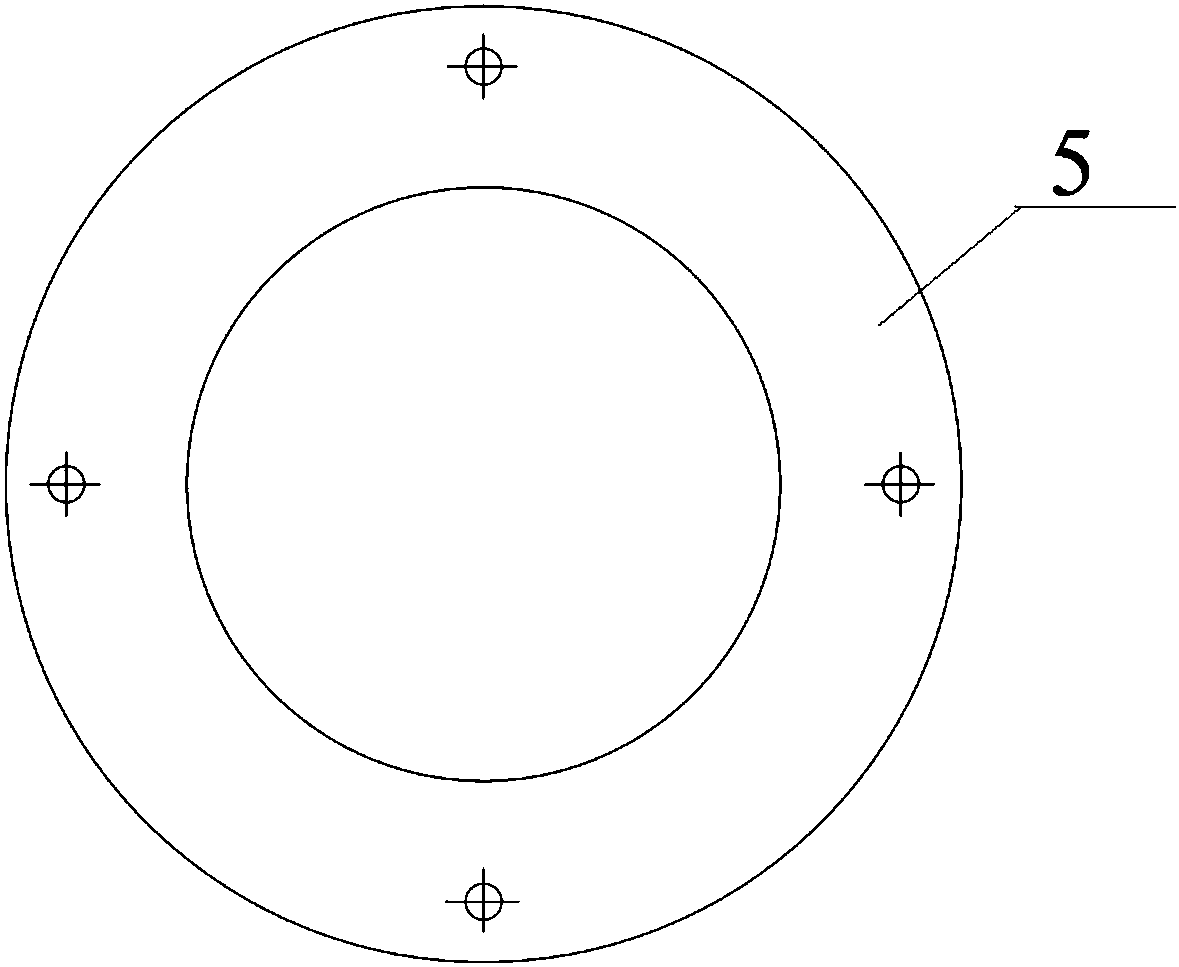

[0023] Such as figure 1 As shown, the preferred embodiment of the present invention mainly includes an image capture device, a controller 9 , a laser 8 , a first glass block, a circular tube 3 , a second glass block and an air duct 14 .

[0024] The first glass block is installed on one end of the round tube 3, and the first glass block has a through hole communicating with one end of the round tube 3; the second glass block is installed on the other end of the round tube 3; 14 is connected with the exhaust port of the round pipe 3; the laser 8 is in the same plane as the first glass block, and the laser light emitted by the laser 8 enters the round pipe 3 through the first glass block; the image pickup device is connected with the first glass block On the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com