Three-dimensional full-cross-section aeration step

A full-section, aerated sill technology, applied in water conservancy projects, marine engineering, coastline protection and other directions, can solve problems such as increasing project cost and increasing project construction difficulty, and achieve the effect of reducing construction difficulty and saving project cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention is further defined below in conjunction with specific embodiments:

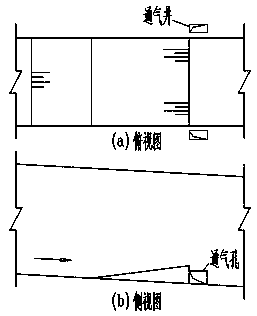

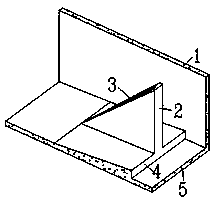

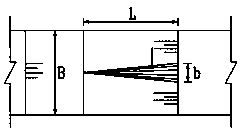

[0023] The invention provides a three-dimensional full-section aeration sill (see figure 2 ), including a side wall 1 and a bottom plate 5, the bottom plate 5 is provided with an aerated bottom sill 4, and the thickness of the aerated bottom sill 4 increases gradually along the water flow direction;

[0024] A wedge-shaped middle pier 2 is arranged vertically in the middle of the above-mentioned aerated sill 4. The longitudinal height of the wedge-shaped middle pier 2 gradually increases with the direction of water flow, and its transverse width gradually widens with the direction of water flow, so that the originally continuous water body is divided into left-right and symmetrical sections. Due to the existence of the piers in the wedge-shaped body, a natural cavity will be formed between the water flows on both sides, and it will naturally communicate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com