Complex frozen soil hydrate storage polyvinyl alcohol drilling fluid

A polyvinyl alcohol and drilling fluid technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of not considering the use of compound hydrate inhibitors, so as to avoid serious expansion of pore size, reduce damage, The effect of good rheology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1, the content of each component in the drilling fluid is: the mass ratio of polyvinyl alcohol is 2.8%, the mass ratio of sodium chloride is 9%, the mass ratio of ethylene glycol is 19%, and the mass ratio of sulfonated phenolic resin SMP-2 is 1.8%, the mass ratio of potassium polyacrylate is 1.8%, the mass ratio of xanthan gum is 0.4%, the mass ratio of polyvinylpyrrolidone K90 is 0.8%, the mass ratio of polyethylene oxide is 0.8%, the mass ratio of propylene glycol phenyl ether is 0.8%, and the rest The component is preparation water.

Embodiment 2

[0040] Embodiment 2, the content of each component in the drilling fluid is: the mass ratio of polyvinyl alcohol is 3%, the mass ratio of sodium chloride is 10%, the mass ratio of ethylene glycol is 20%, and the mass ratio of sulfonated phenolic resin SMP-2 is 2%, the mass ratio of potassium polyacrylate is 2%, the mass ratio of xanthan gum is 0.5%, the mass ratio of polyvinylpyrrolidone K90 is 1%, the mass ratio of polyethylene oxide is 1%, the mass ratio of propylene glycol phenyl ether is 1%, and the rest The component is preparation water.

Embodiment 3

[0041] Embodiment 3, the content of each component in the drilling fluid is: the mass ratio of polyvinyl alcohol is 3.2%, the mass ratio of sodium chloride is 11%, the mass ratio of ethylene glycol is 21%, and the mass ratio of sulfonated phenolic resin SMP-2 is 2.2%, the mass ratio of potassium polyacrylate is 2.2%, the mass ratio of xanthan gum is 0.6%, the mass ratio of polyvinylpyrrolidone K90 is 1.2%, the mass ratio of polyethylene oxide is 1.2%, the mass ratio of propylene glycol phenyl ether is 1.2%, and the rest The component is preparation water.

[0042] The first, second, and third drilling fluid configuration methods in the above-mentioned embodiments are conventional drilling fluid configuration methods, and are evaluated by the following experimental methods:

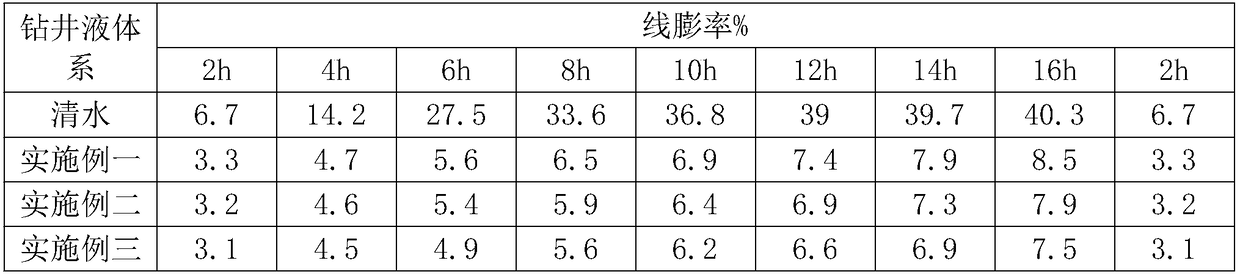

[0043] 1 Evaluation of drilling fluid shale hydration inhibition

[0044] In the indoor evaluation of the relevant performance of the drilling fluid, the inhibition evaluation experiment is an important p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com