Highway environment-friendly epoxy biological asphalt material and preparation method thereof

A bio-asphalt, environmentally friendly technology, used in building thermal insulation materials, building structures, building components, etc., can solve problems such as difficulty in taking into account high and low temperature performance and long curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

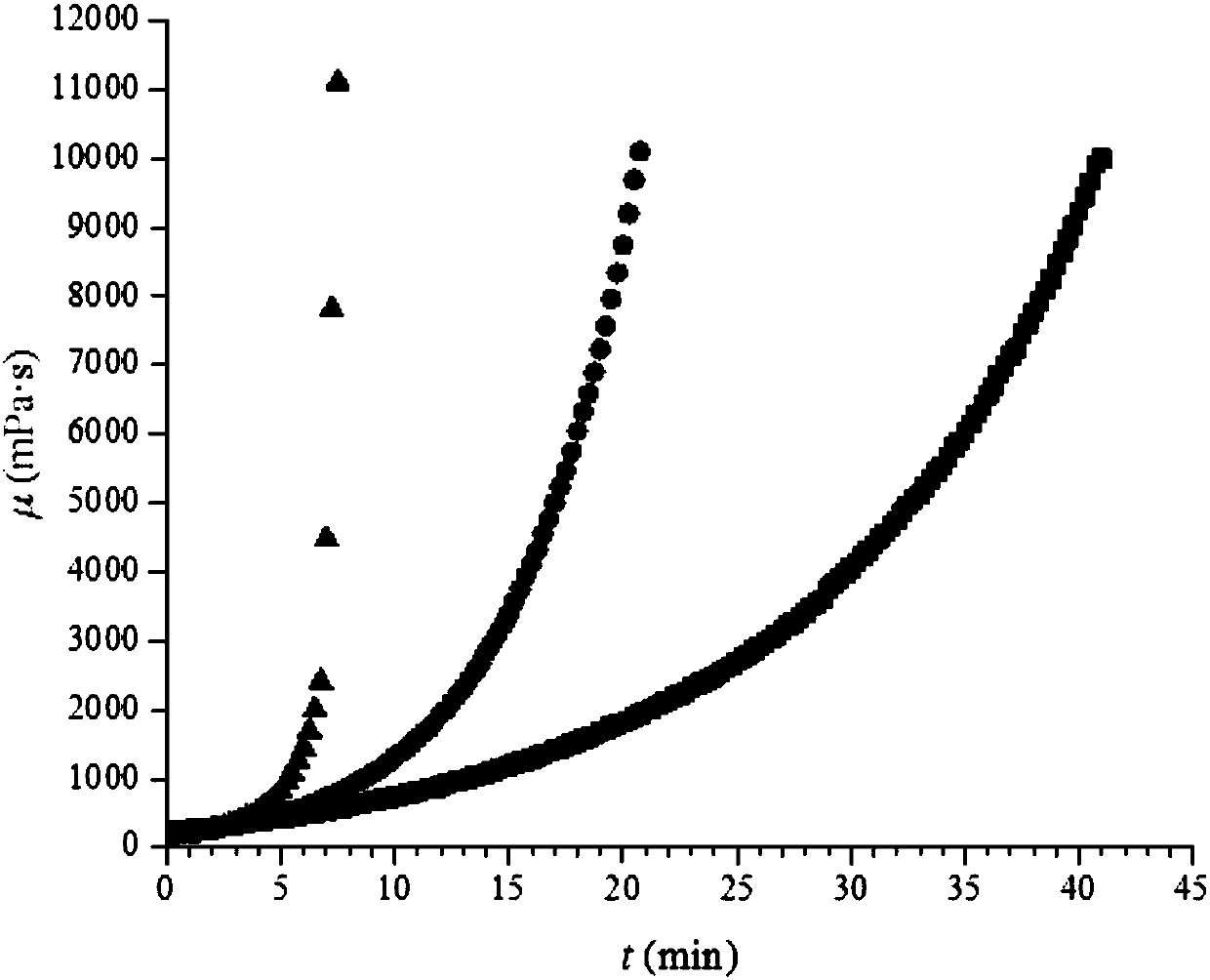

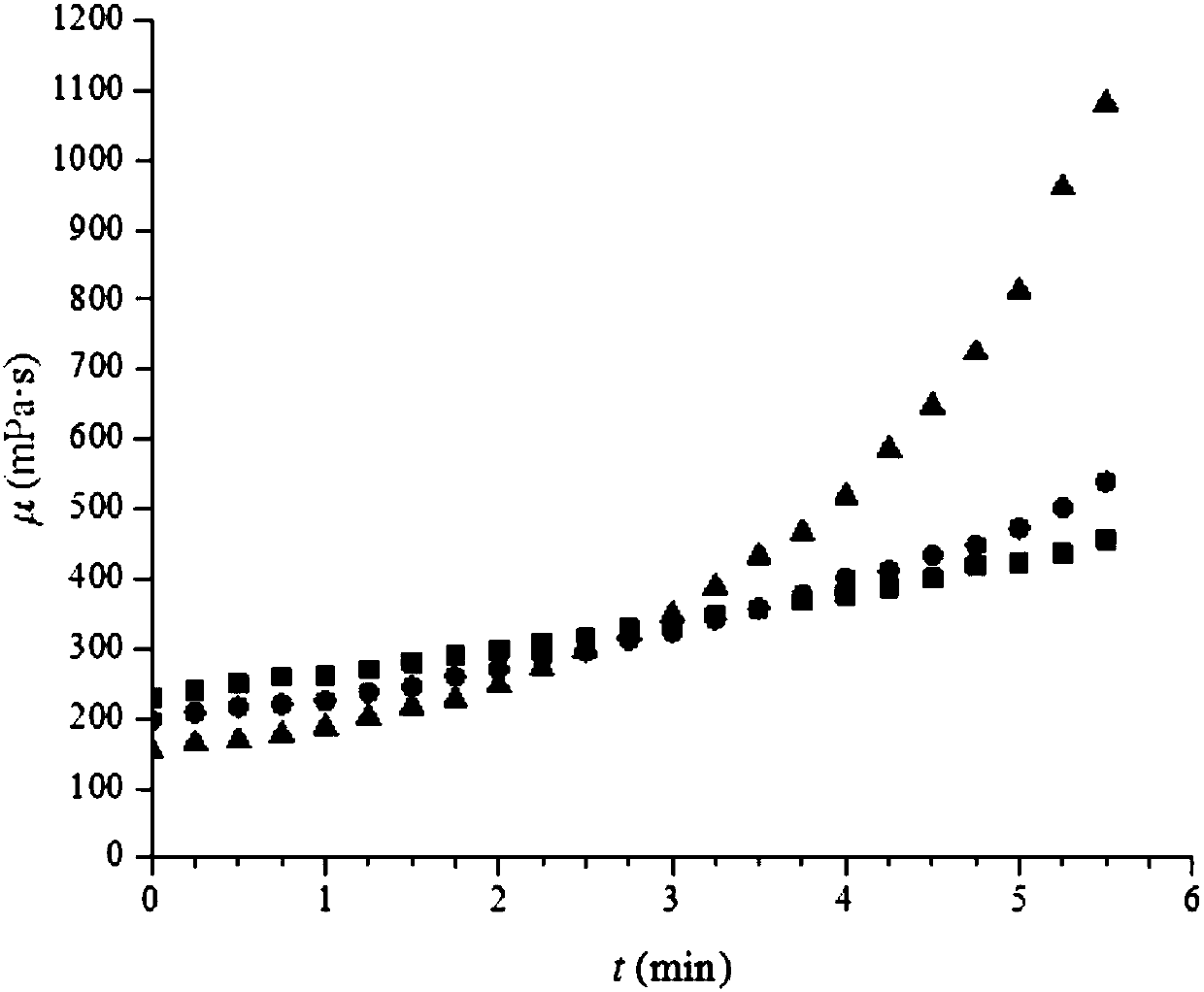

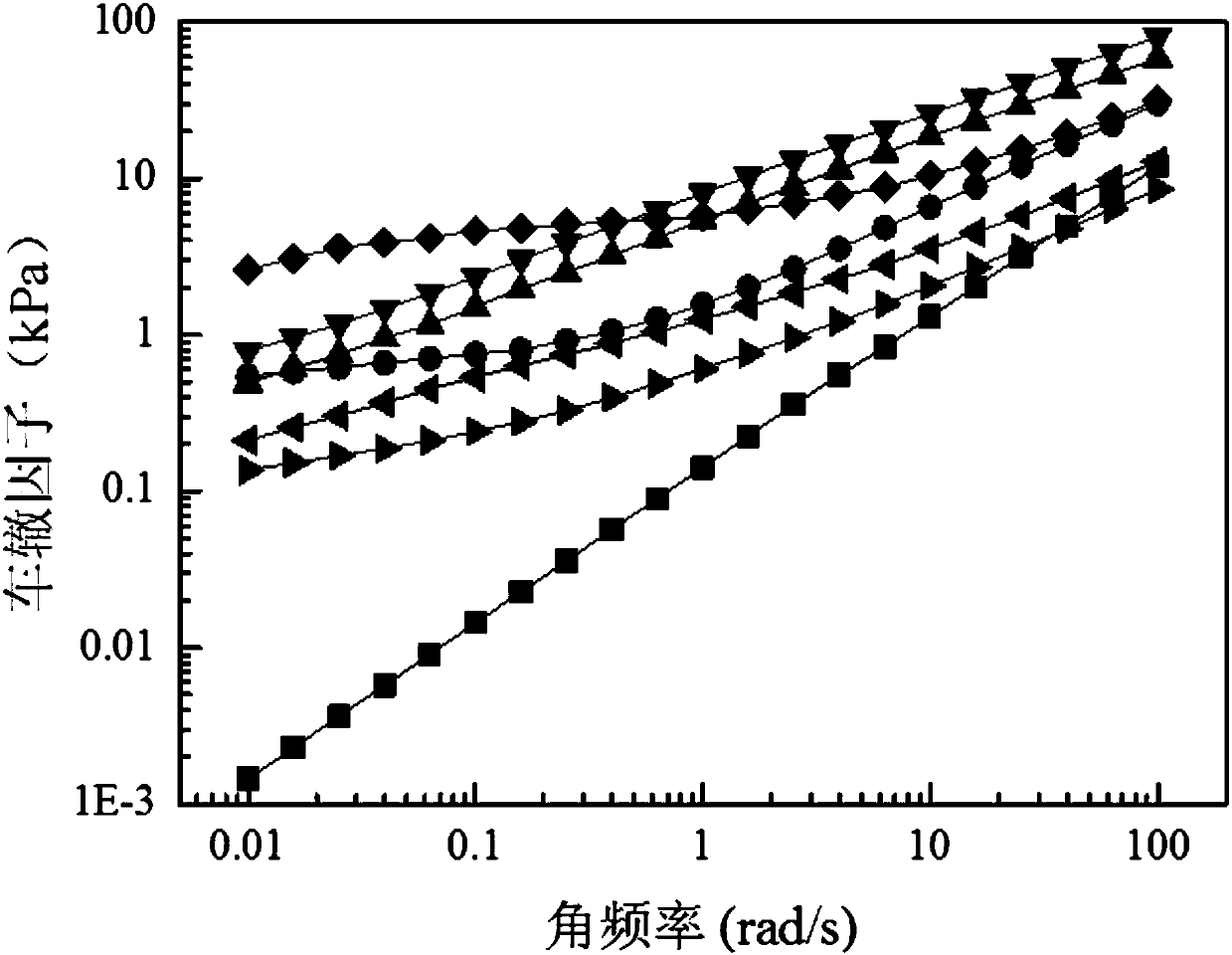

[0017] Specific implementation mode 1: In this embodiment, the environment-friendly epoxy bio-asphalt material for road use is composed of 100 parts by mass of bio-asphalt, 35-60 parts of curing agent, 1-2 parts of strong alkali, 0.5-1 part of defoamer and 20 parts by mass. ~34 parts of epoxy resin, wherein the curing agent is an adduct of diethylenetriamine and butyl glycidyl ether.

[0018] In this embodiment, the high temperature performance and low temperature performance of the components are separated and different components are used to meet the requirements of material performance, and an epoxy bio-asphalt material with excellent high and low temperature performance, which can be quickly cured and used to repair key parts of the road is prepared. .

specific Embodiment approach 2

[0019] Embodiment 2: This embodiment is different from Embodiment 1 in that the strong base is granular or powdered sodium hydroxide or potassium hydroxide.

specific Embodiment approach 3

[0020] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the defoamer is a mineral oil defoamer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com